Method for recovering lithium ion battery wastes by using thermal cracking

A lithium-ion battery, ion battery technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of complex process, high cost, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

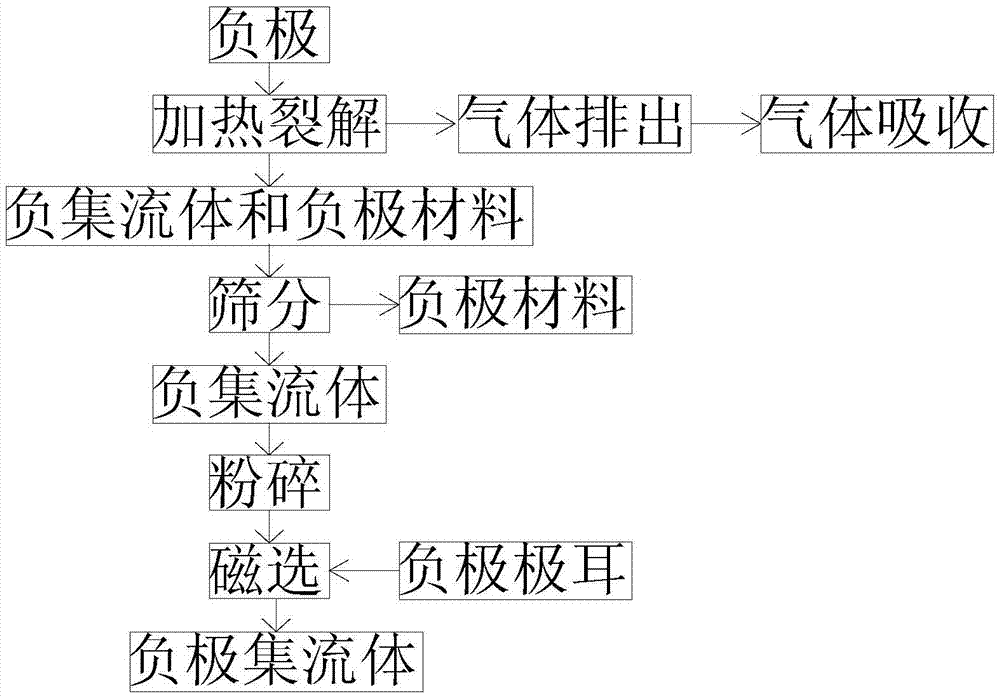

[0026] Reference figure 1 As shown, this embodiment provides a process for recycling the negative electrode of a waste lithium ion battery. The specific process is as follows:

[0027] The negative electrode produced in production or separated from the waste lithium ion battery is put into a high-temperature pyrolysis furnace for heating, and the binder bonding the negative electrode material and the negative electrode current collector is broken by heating, so that the negative electrode material is separated from the current collector On and off. Since the binder usually used to bond the negative electrode material and the negative electrode current collector is polyvinylidene tetrafluoroethylene, and polyvinylidene tetrafluoroethylene starts to decompose from 390 degrees, so the temperature of the high temperature cracking furnace is generally controlled at 400-450 degrees. Exhaust the gas produced by heating and cracking, absorb the exhaust gas, and then comprehensively utili...

Embodiment 2

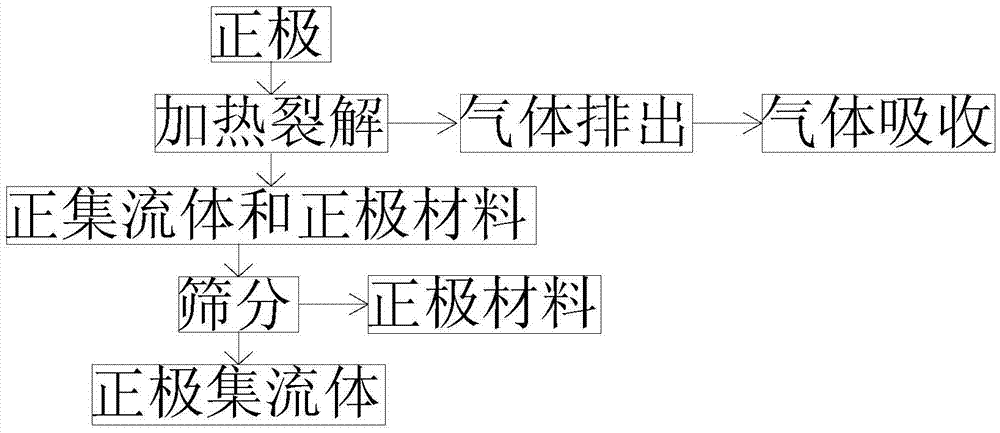

[0029] Reference figure 2 As shown, this embodiment provides a process for recycling the anode of a waste lithium-ion battery. The specific process is as follows:

[0030] The positive electrode produced from the production or separated from the waste lithium ion battery is put into a high-temperature pyrolysis furnace for heating, and the binder bonding the positive electrode material and the positive electrode current collector is cracked by heating, so that the positive electrode material is collected from the positive Separated from the fluid. Since the binder usually used to bond the positive electrode material and the positive electrode current collector is polyvinylidene tetrafluoroethylene, and polyvinylidene tetrafluoroethylene starts to decompose from 390 degrees, so the temperature of the high temperature cracking furnace is generally controlled at 400-450 degrees. The gas produced by thermal cracking is discharged, and the discharged gas is absorbed and comprehensive...

Embodiment 3

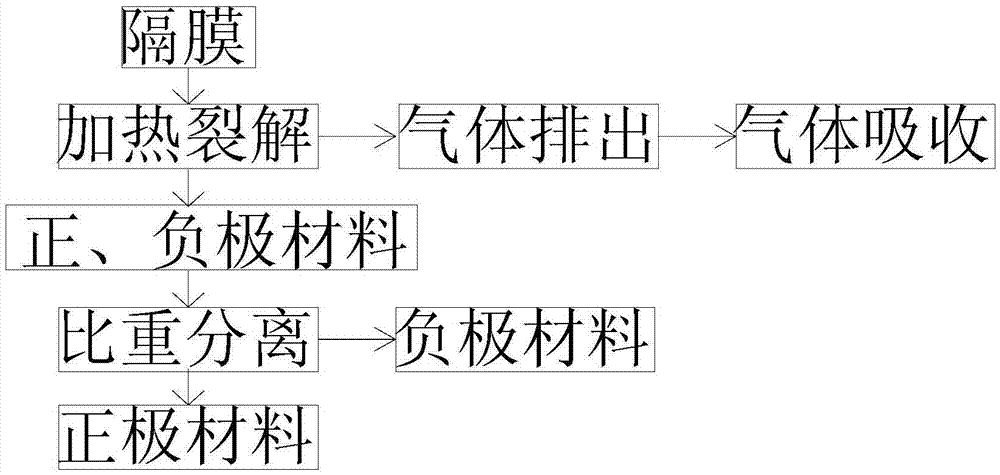

[0032] Reference image 3 As shown, this embodiment provides a process for recycling the separators of waste lithium-ion batteries. The specific process is as follows:

[0033] The separator separated from the waste lithium ion battery is put into a high-temperature thermal cracking furnace for heating, and the separator is cracked by heating. Since the commonly used diaphragm is made of polyethylene or polypropylene, and the decomposition temperature of polyethylene or polypropylene is 400-430 degrees, the furnace temperature is controlled at 400-450 degrees. Exhaust the gas produced by thermal cracking, absorb the exhaust gas, and then comprehensively utilize it; what is left in the furnace is the mixture of the positive electrode material and the negative electrode material falling off the diaphragm. The positive electrode material and the negative electrode material can be made by the principle of specific gravity. Phase separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com