Permanently-stable heat insulating brick for limekiln

A stable, lime kiln technology, used in the field of refractory materials, can solve the problems of complex masonry process, and achieve the effects of excellent refractory performance, low density and excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

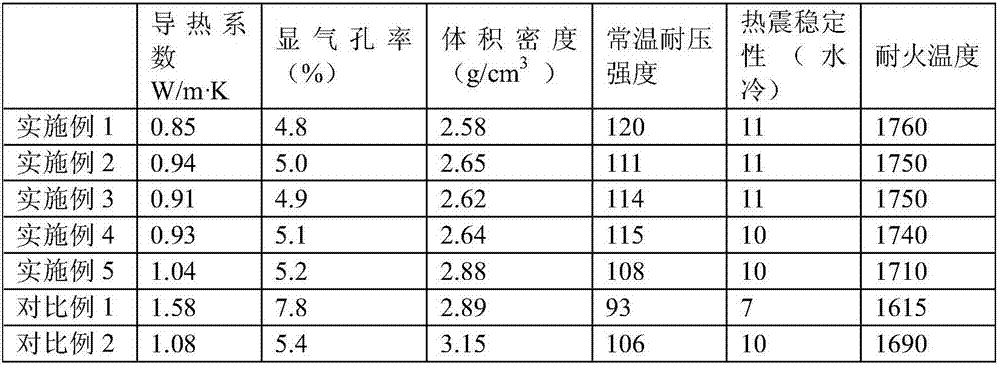

Examples

Embodiment 1

[0013] A permanent and stable heat insulating brick for lime kiln, which is composed of the following components in parts by mass: 12.5 parts of burnt gems with a particle size of less than 1 mm, 12.5 parts of burnt gems with a particle size of 3-5 mm, and 12.5 parts of burnt gems with a particle size of less than 5 parts of 1mm ceramsite, 10 parts of ceramsite with a particle size between 1-3mm, 15 parts of ceramsite with a particle size of 3-8mm, 7.5 parts of kaolinite clay, 12.5 parts of floating beads, barium aluminate cement 20 parts, 5 parts of barium-zirconium aluminate cement, 4 parts of sintered magnesia.

Embodiment 2

[0015] A permanent and stable heat insulating brick for lime kiln, which is composed of the following components in parts by mass: 12.5 parts of burnt gems with a particle size of less than 1 mm, 12.5 parts of burnt gems with a particle size of 3-5 mm, and 12.5 parts of burnt gems with a particle size of less than 5 parts of 1mm ceramsite, 10 parts of ceramsite with a particle size between 1-3mm, 15 parts of ceramsite with a particle size of 3-8mm, 7.5 parts of kaolinite clay, 12.5 parts of floating beads, barium aluminate cement 20 parts, 5 parts of barium-zirconium aluminate cement.

Embodiment 3

[0017] A permanent and stable heat insulating brick for lime kiln, which is composed of the following components in parts by mass: 10 parts of burnt gems with a particle size of less than 1 mm, 10 parts of burnt gems with a particle size of 3-5 mm, and 10 parts of burnt gems with a particle size of less than 1 mm. 4 parts of 1mm ceramsite, 8 parts of ceramsite with a particle size between 1-3mm, 12 parts of ceramsite with a particle size of 3-8mm, 5 parts of kaolinite clay, 10 parts of floating beads, barium aluminate cement 16 parts, 4 parts of barium-zirconium aluminate cement, and 3 parts of sintered magnesia. The ceramsites are ultra-light density ceramsites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com