Method for producing carbon, gas, tar and liquor by biomass pyrolysis

A biomass pyrolysis and production method technology, applied in the production field of biomass pyrolysis charcoal gas oil, can solve the problems of poor continuity, environmental pollution, long carbonization time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

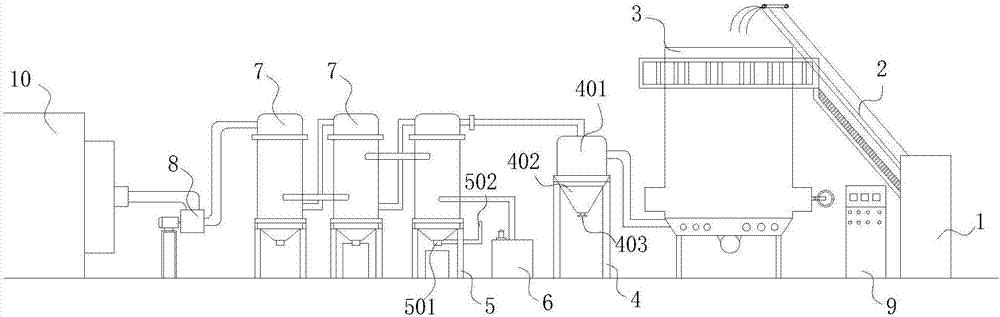

[0030] See attached figure 1 , the equipment of the production line that the production method of biomass pyrolysis carbon gas oil liquid of the present invention adopts comprises:

[0031] Material drying equipment 1, the material drying equipment 1 is used to dry the material to be carbonized;

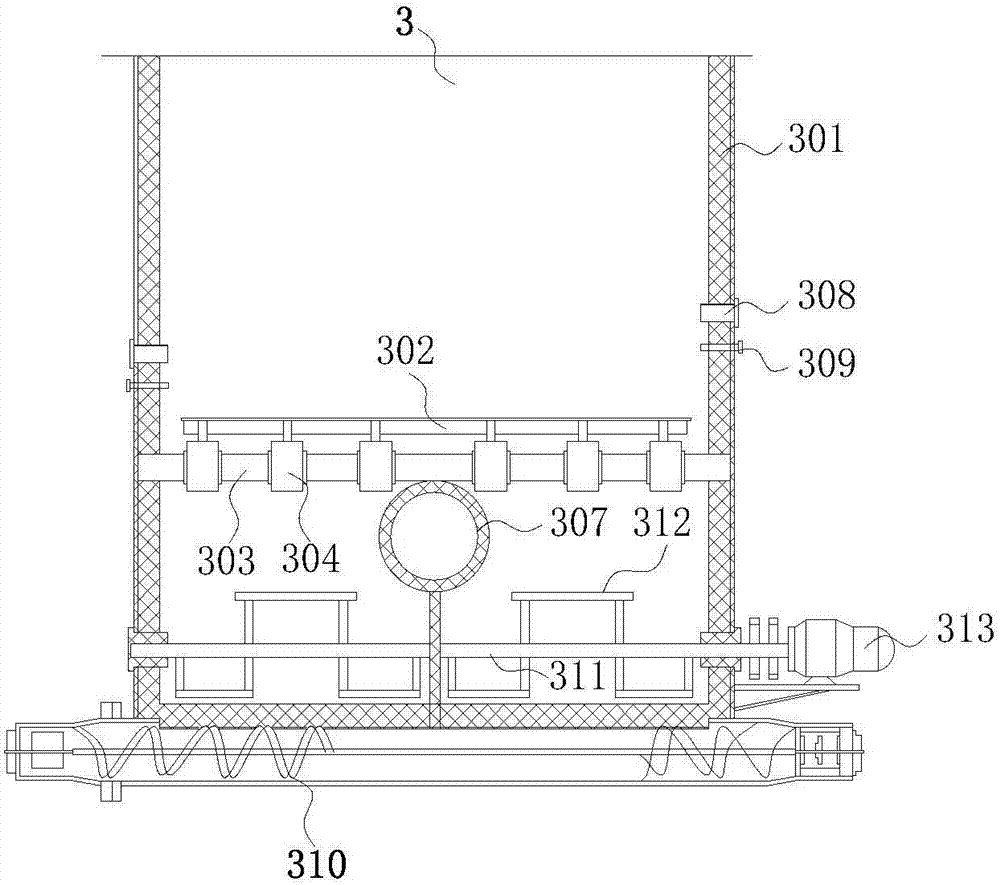

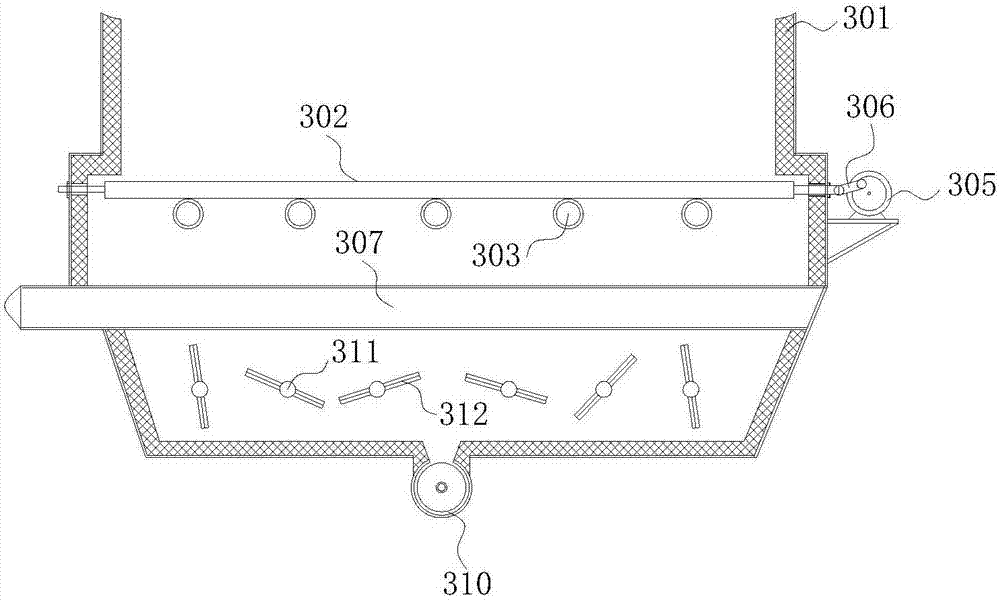

[0032] The gas charcoal furnace 3 connected to the discharge port of the material drying equipment 1 through the material conveyor 2 at the feed port, the carbonization of the material is realized through the gas charcoal furnace 3, and the combustible gas is pyrolyzed at the same time;

[0033] The dust remover 4 connected with the gas charcoal furnace 3 furnace body 301 through a connecting pipe, the combustible gas generated in the gas charcoal furnace 3 enters the dust remover 4 to remove the dust in the combustible gas;

[0034] The wood vinegar liquid separator 5 that is connected with the air outlet of the dust remover 4 through the connecting pipe;

[0035] The spray tower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap