Heating system of marsh gas tank and the marsh gas tank

A heating system and biogas digester technology, applied in the field of biogas digester heating system and biogas digester, can solve the problems of low gas production rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

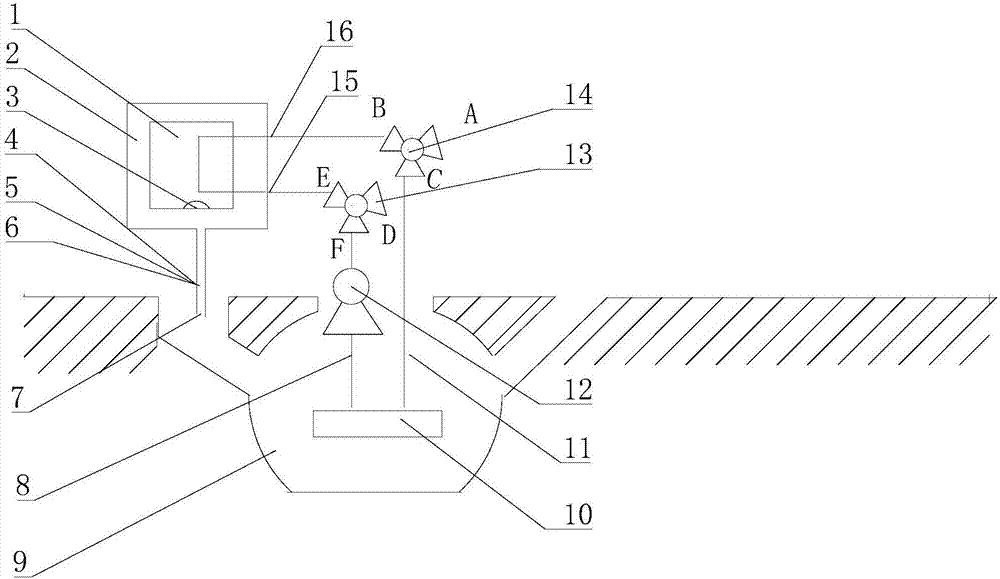

[0026] Embodiments of the present invention are as follows, see figure 1 The biogas digester heating system shown includes such as figure 2 The shown control system, heat exchange system and self-excitation system, more specifically, the control system includes a controller 17, the self-excitation system includes an outflow pipeline 15 and a return pipeline 16 communicated with the outflow pipeline 15, and the self-excitation system includes The self-exciting device 2 and the combustion chamber 1 communicate with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com