Full-ecological, intelligent and multifunctional environmental protection methane generator

A biogas generator, multi-functional technology, applied in gas production bioreactors, biochemical instruments, bioreactor/fermenter combination, etc., can solve the problems of biogas generators such as low gas production rate, long cycle, and environmental pollution. To achieve the effect of shortening the gas production cycle, increasing the gas production rate and relieving the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

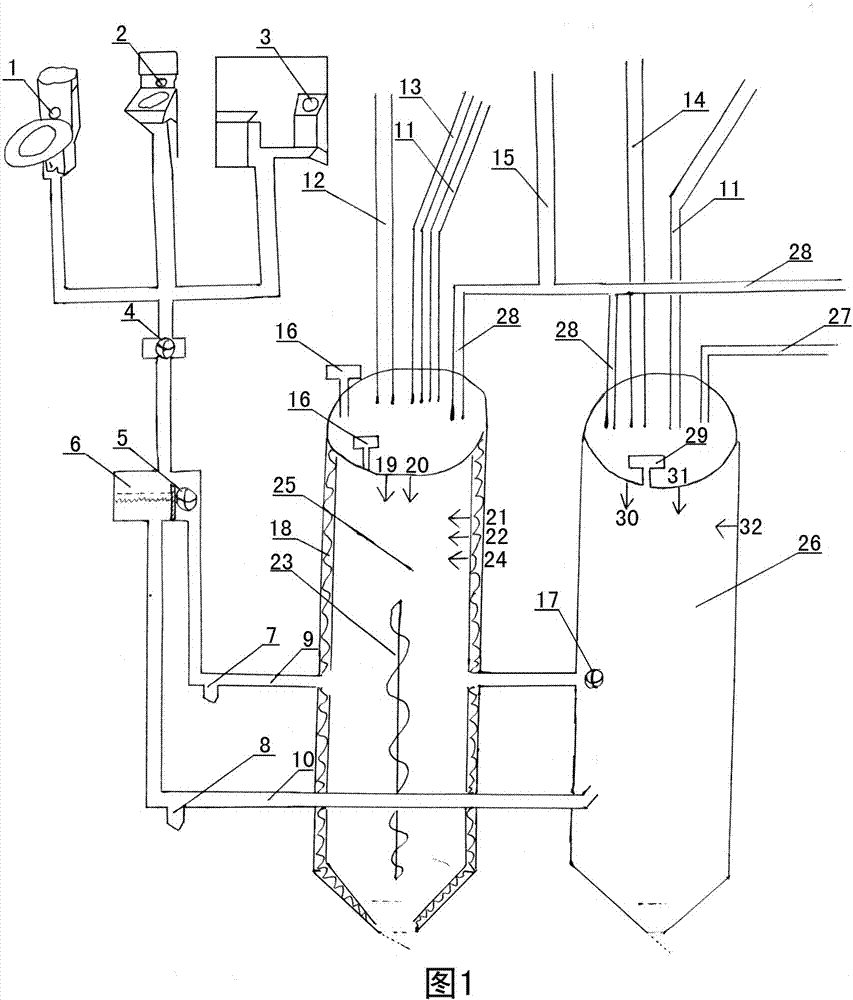

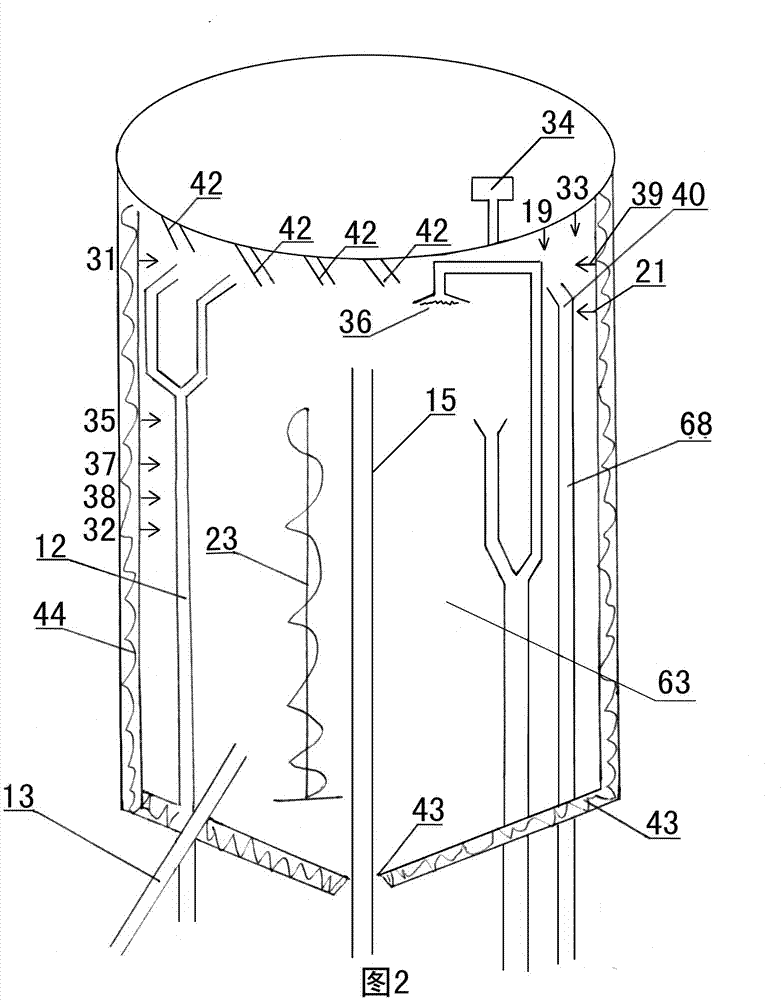

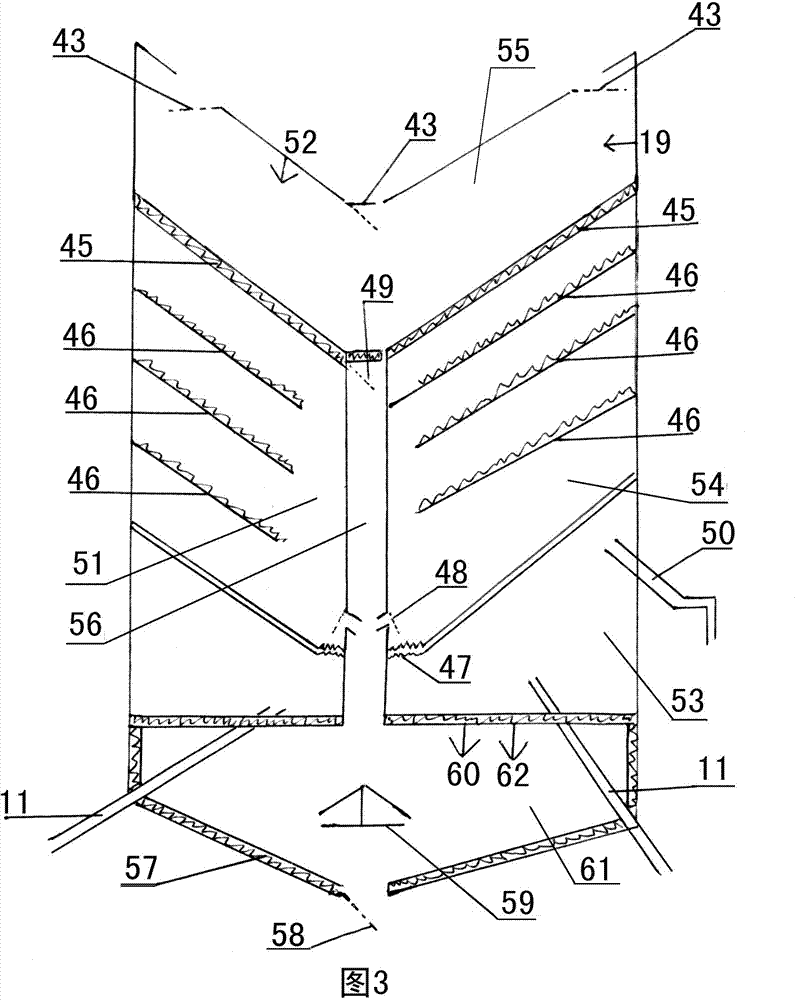

[0049] Examples see Figure 1-6 As shown, this fully ecologically intelligent, multifunctional and environmentally friendly biogas generator includes a tank body, which is distributed with an anaerobic digester 63, a solid-liquid separation chamber 55, a biogas slurry filter room 54, and a biogas slurry distillation chamber from top to bottom. Chamber 53, drying chamber 61, retting tank 25, water storage tank 26 and overflow tank 73.

[0050] see figure 1 As shown, the toilet, washbasin, and garbage bin outside the tank are respectively equipped with toilet infrared detector 1, washbasin infrared detector 2, straw, stem, garbage infrared detector 3, toilet, washbasin, garbage The tanks are all connected to the solid-liquid separation tank 6, and a siphon centrifugal pump 4 is installed on the connected main pipeline. A solid material pulverizer 5 is installed in the solid-liquid separation tank 6, and the solid-liquid separation tank 6 is connected to the inside of the tank t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com