Environment-friendly paper making equipment

A kind of papermaking equipment and environmental protection technology, applied in the field of environmental protection papermaking equipment, can solve the problems of paper waste waste, cost increase, high pollution, etc., and achieve the effect of reducing waste and paper production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples are provided to specifically describe the present invention. It is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention. Those skilled in the art according to the present invention SUMMARY OF THE INVENTION Some non-essential improvements and adjustments made to the present invention still belong to the protection scope of the present invention.

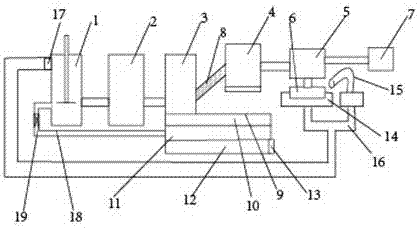

[0014] Such as figure 1 Shown: an environment-friendly papermaking equipment, including: paper scrap beater 1, pulp refiner 2, paper machine 3, dryer 4, calender 5, paper cutter 6, winder 7, perforated tube 8 , sewage sedimentation tank 9, filter layer 10, clear water layer 11, sedimentation layer 12, sewage outlet 13, waste paper recycling tank 14, ventilation equipment 15, conveyor belt 16, delivery port 17, water flow pipe 18, valve 19, the paper Chip beater 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com