Adaptive double reamer dredging device

A double reamer, self-adaptive technology, applied in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve problems such as silt splashing, secondary pollution, increased energy consumption, etc., to achieve Reduce leakage, improve adaptability, and increase the effect of inhalation concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

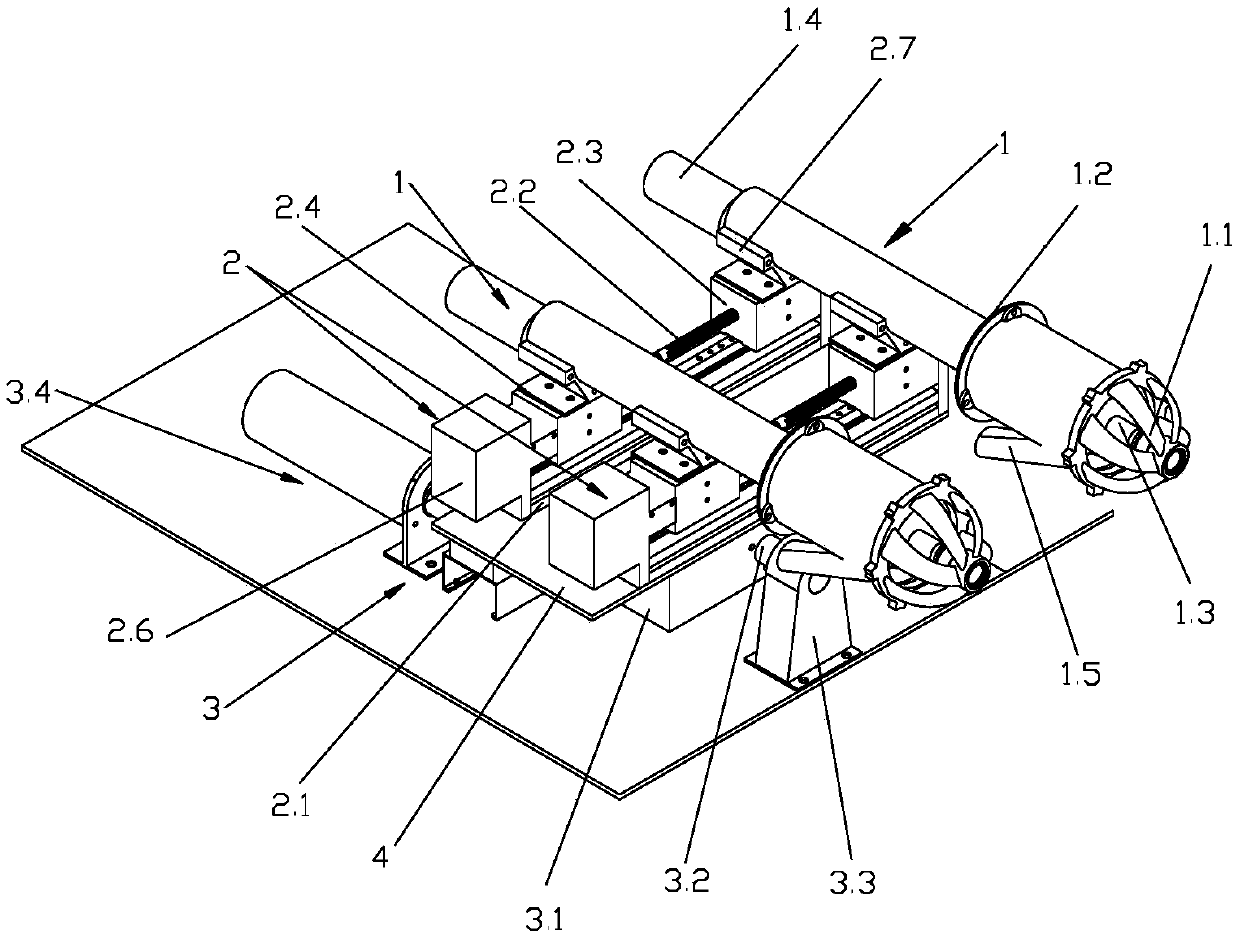

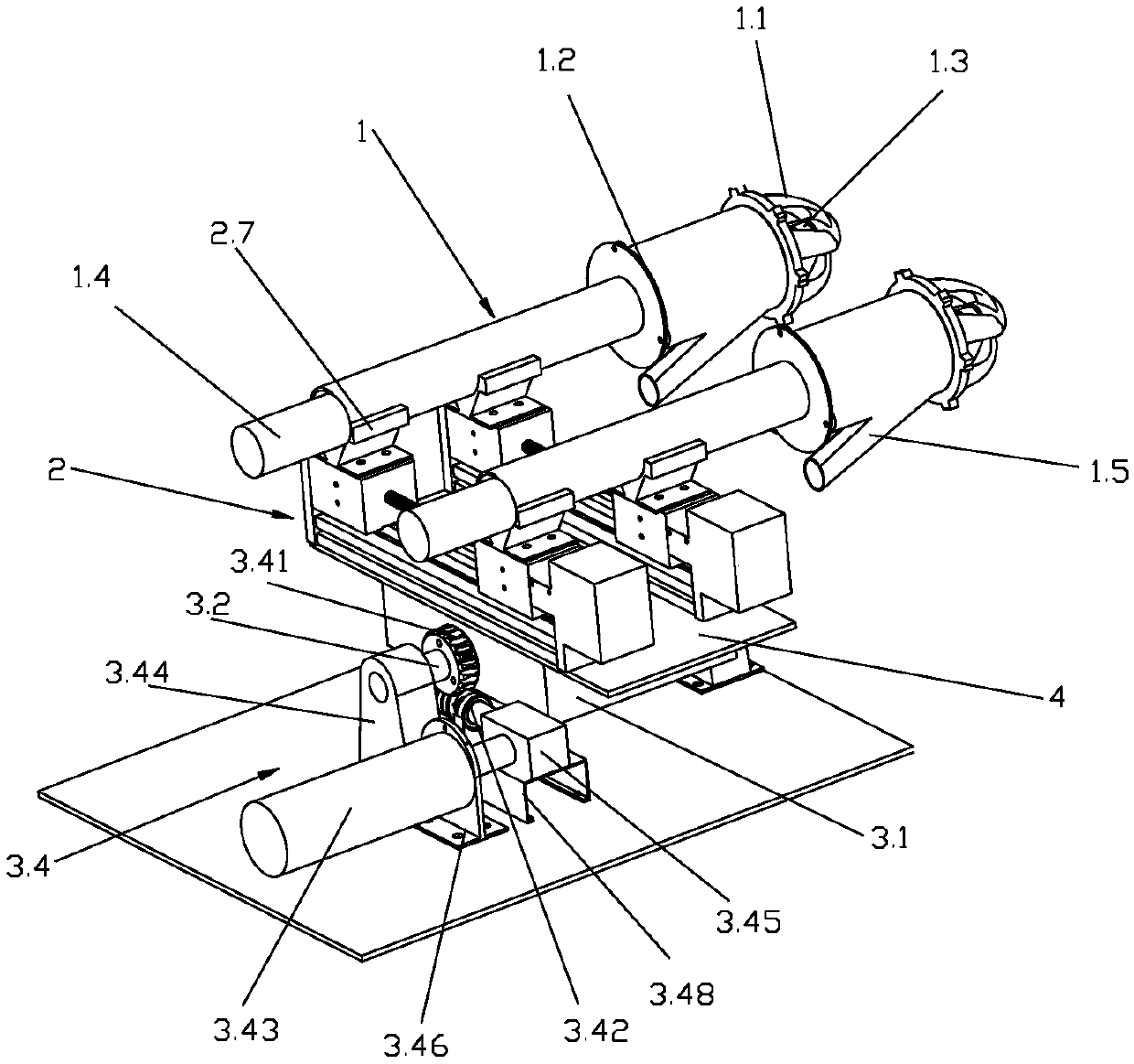

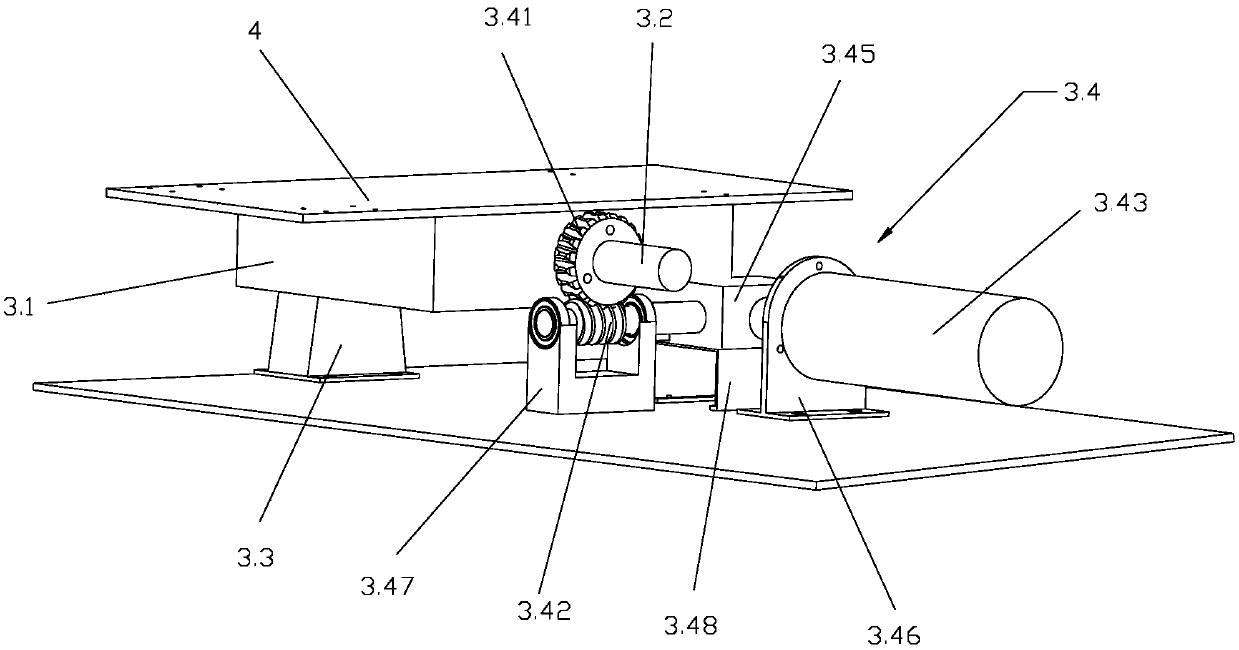

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0034]An adaptive double reamer dredging device shown in the figure includes two reamer mechanisms 1 arranged in parallel, two traverse mechanisms 2 arranged perpendicularly to the reamer mechanism 1, and a luffing mechanism 3; The reamer mechanism 1 includes a reamer 1.1, a sleeve 1.2, a reamer shaft 1.3 passing through the sleeve 1.2, and a first motor 1.4 for driving the reamer 1.1 to rotate. The suction port 1.5. The reamer 1.1 is crown-shaped, the wrapping angle of the knife arm is 30-45°, the diameter of the reamer is 80-100 mm, and the inner hole is 10-20 mm. One end of the reamer shaft 1.3 runs through the sleeve 1.2 and is fixedly connected to the center hole of the reamer 1.1, and the other end of the reamer shaft 1.3 is connected to the output shaft of the first motor 1.4; the reamer shaft 1.3 is installed on the sleeve through sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com