Manufacturing technological method of toilet bowl with artificial stone housing and ceramic liner integrally molded

A ceramic liner and manufacturing process technology, used in flush toilets, water supply devices, buildings, etc., can solve problems such as low yield, environmental pollution, waste of resources, etc., and achieve high deformation resistance and impact resistance. , the effect of large production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and embodiment the present invention is described further in detail:

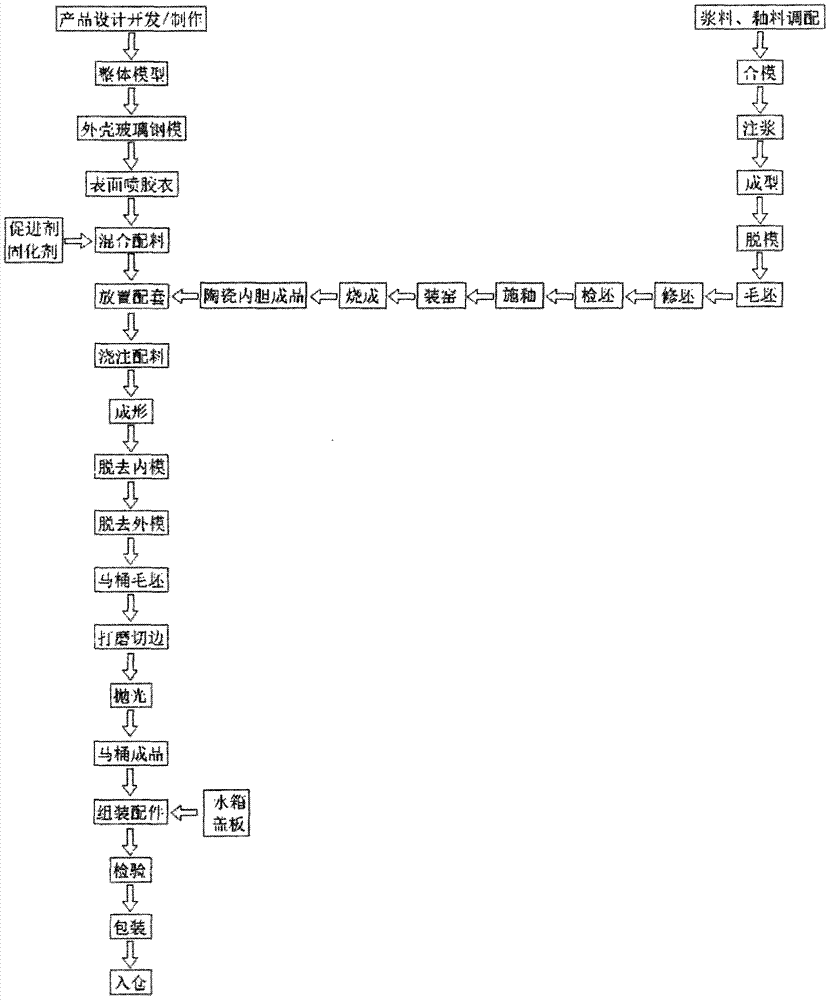

[0048] exist figure 1 , discloses a toilet manufacturing process method of the present invention with an integrally formed artificial stone shell and a ceramic liner. The process method is divided into two parts: process steps and process conditions. The process flow of the process steps is further divided into three processes, namely The first process of the artificial stone shell, the second process of the ceramic liner, and the third process of the synthesis of the shell and liner.

[0049] First, the process steps of running three processes:

[0050] Its first flow process process step is:

[0051] 1. Product design and development / manufacturing; 2. Overall model; 3. Shell FRP mold; 4. Surface spray gel coat; 5. Mixing ingredients (including accelerator and curing agent); 6. Placement and matching.

[0052] Its second flow process process step is:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com