In-vivo electrohydraulic lithotripter circuit and pulse discharge lithotripsy method

A lithotripsy instrument and circuit technology, applied in medical science, surgery, etc., can solve the problems of too large surgical operation site, inability to apply electric shock frequency and amplitude, and poor positioning accuracy, so as to increase applicability and improve lithotripsy effect , The effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

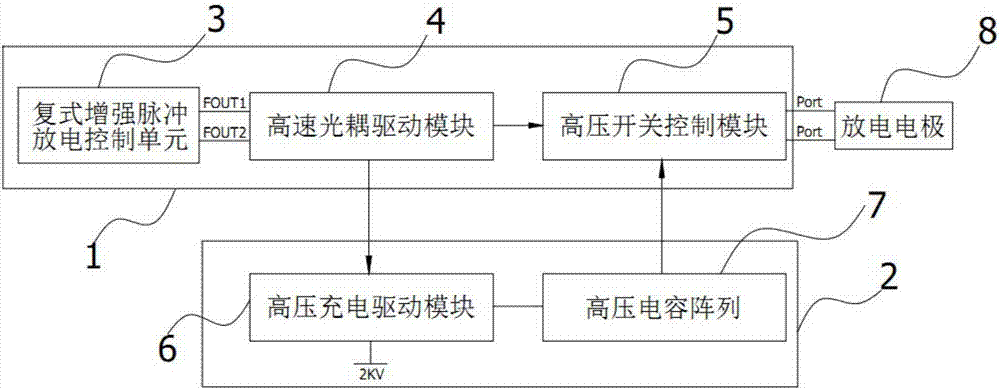

Method used

Image

Examples

Embodiment 1

[0051] In the optional scheme of this embodiment, such as Figure 5 As shown, preferably, the pulse discharge adopts three consecutive discharge pulses. The specific operation form is: the compound enhanced pulse discharge control unit 3 controls the high voltage switch control module 5 to output 3 consecutive discharge pulses, the discharge interval is 300 milliseconds, the discharge time is 0.5 microseconds, and the discharge voltage is 2000 volts. Due to the long interval between the three-strike discharge pulses and the continuous discharge times are only three times, it is suitable for shocking soft stones.

Embodiment 2

[0053] In the optional scheme of this embodiment, such as Image 6 As shown, preferably, the pulse discharge adopts ten consecutive discharge pulses. The specific operation form is: the compound enhanced pulse discharge control unit 3 controls the high voltage switch control module 5 to output 10 consecutive discharge pulses, the discharge interval is 14 milliseconds, the discharge time is 0.5 microseconds, and the discharge voltage is 2000 volts. Since the number of discharges of the ten-strike discharge pulse is more, the number of continuous discharges is ten times, which is suitable for shocking soft stones.

Embodiment 3

[0055] In the optional scheme of this embodiment, such as Figure 7 As shown, preferably, the pulsed discharge employs rapid cycle discharge pulses. The specific operation form is: the compound enhanced pulse discharge control unit 3 controls the high-voltage switch control module 5 to output a group of 5 continuous discharge pulses at intervals of 1 second, the discharge interval is 18 milliseconds, the discharge time is 0.5 microseconds, and the discharge voltage is 2000 volts . Because the rapid cycle discharge pulses output pulse discharges in groups, the number of discharge pulses is more and the interval time is shorter, which is suitable for shocking hard stones.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com