New method for determining process execution sequence in hydrogen network node hydrogen

A technology that executes the sequence and determines the process, applied in the field of hydrogen network, can solve the problem that the target of hydrogen consumption cannot be given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

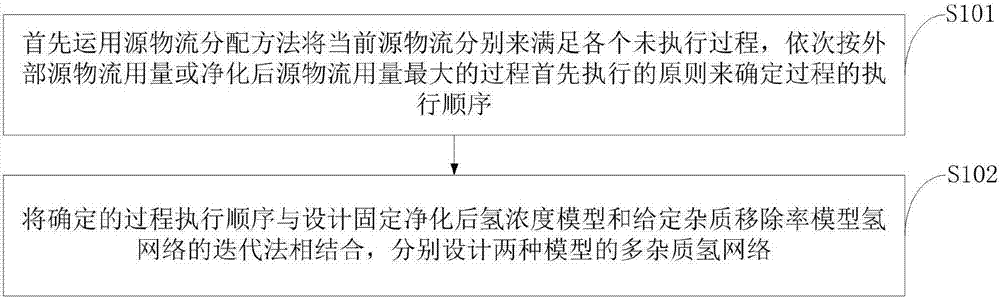

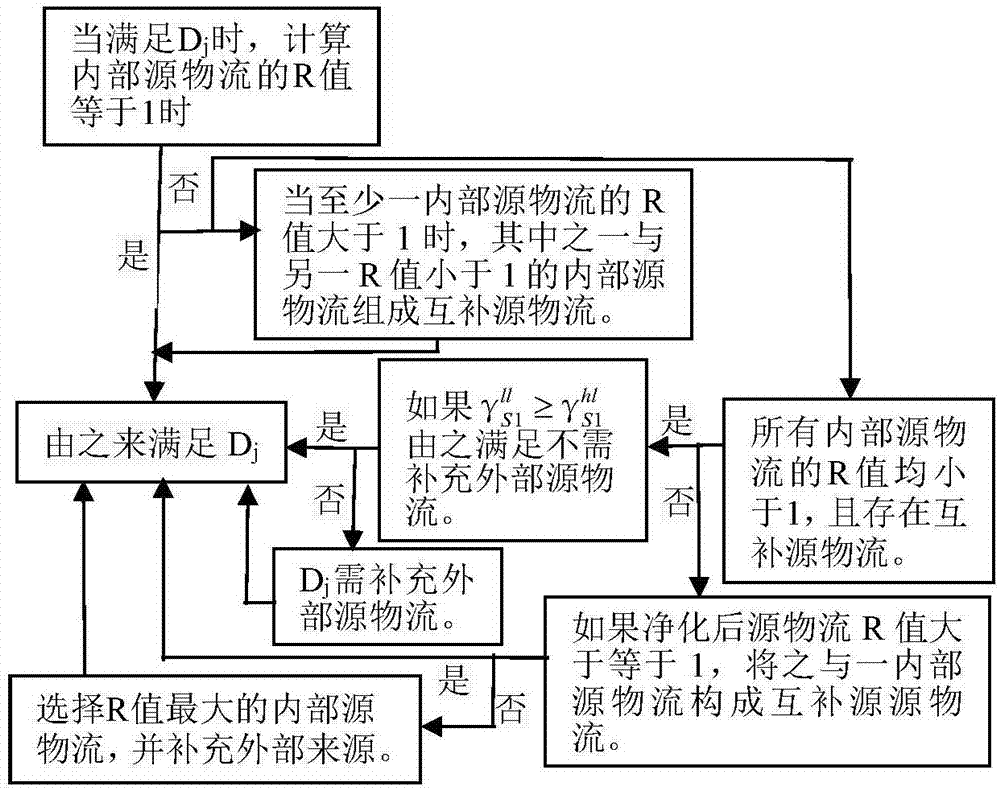

Method used

Image

Examples

example

[0124] The above example is designed according to the fixed concentration model after purification (HR=95%, Creg=(0.03,0.25,0.72)mol%) and the given impurity removal rate model (HR=95%, R=95%).

example 1

[0125] Example 1, it is known that the hydrogen recovery rate is HR=95%, and the impurity removal rate IR=95%.

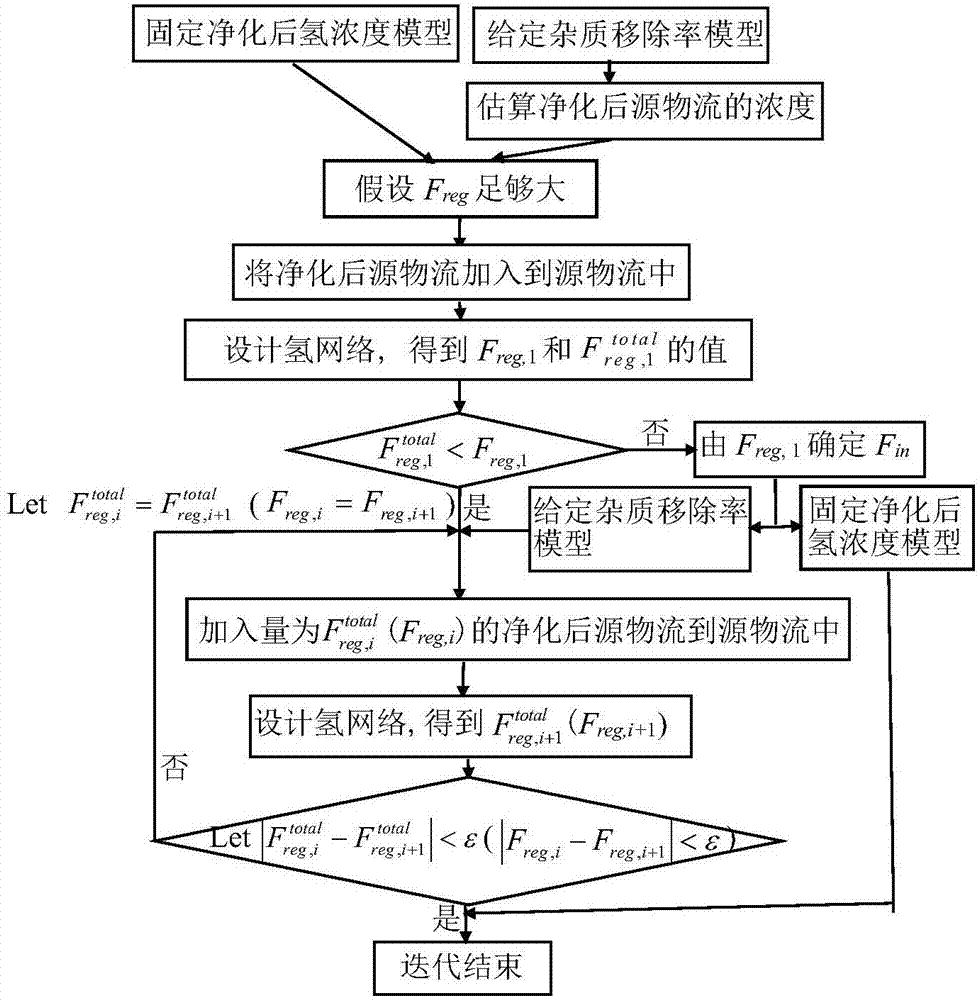

[0126] After determining the order of process execution, all processes are also satisfied, that is, the first iteration is completed. Because the amount of the last recycled source stream in the first iteration is 209.37 mol·s-1, the purified source stream is 175.38 mol·s-1 after purification. The amount of source stream after purification is 182.40 mol·s-1. Because of 175.38 <182.40, so use 175.38 as the initial value of the next iteration, and get the final design after four iterations. The results of each iteration are shown in Table 3.

[0127] Table 3. Iterative design results of Case 1

[0128]

[0129] See you in the final design Figure 4 , The designed external source stream consumption is 41.53mol·s-1, the source stream after purification is 172.89mol·s-1, the amount of the source stream before purification is 206.55mol·s-1, and the impurity concentration after...

example 2

[0130] Example 2: The impurity concentration of the source stream after purification is Creg=(0.03, 0.25, 0.72) mol%, and the hydrogen recovery rate is HR=95%.

[0131] Use the proposed method to design below.

[0132] The method of satisfying the process by the source logistics and the method of judging the execution order of the process are the same as above, and the design steps are similar to the above. Because the amount of the last recycled source stream in the first iteration is 192.60 mol·s-1, the amount of the source stream after its purification is 160.91 mol·s-1. The amount of source stream after purification is 200.47 mol·s-1. Because of 160.91 <200.47, so the amount of 160.91mol·s-1 of the purified source stream obtained from the purification of the source stream before the purification with the amount of 192.60mol·s-1 is not enough. Use it as the initial value of the next iteration and The final design is obtained in six iterations, and the results of each iteration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com