Continuous automatic quick cleaning and paste filling production line for lamb lungs

An automated sheep and production line technology, applied in slaughtering, meat processing equipment, food science, etc., can solve the problems of uneven quality and hygiene conditions, low standardization, time-consuming and labor-intensive problems, and achieve a high degree of automation and standardization, The effect of high health quality and safety and strong application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

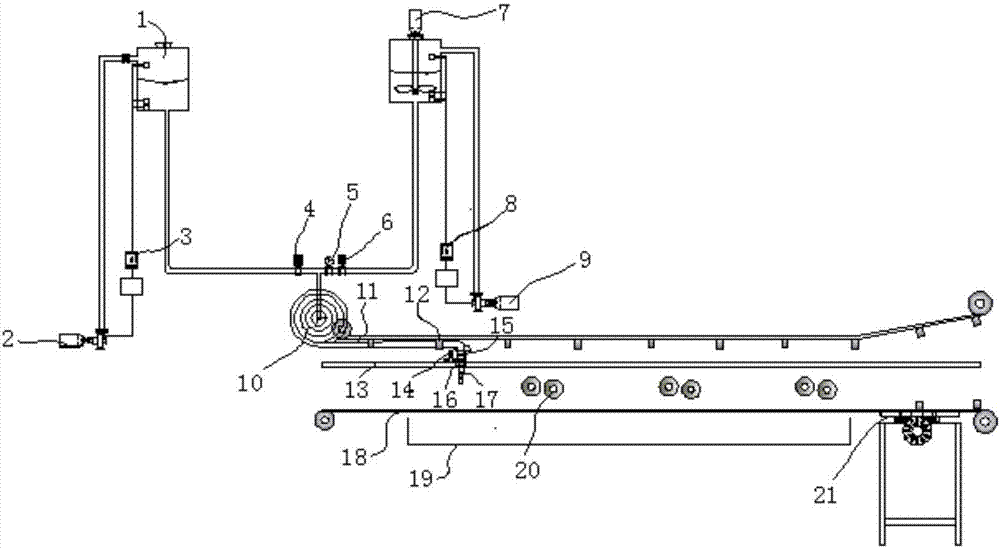

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0019] refer to figure 1 , a continuous automatic sheep lung fast cleaning grouting production line, including a main conveyor belt 18 and water storage tanks 1 for water storage and slurry storage respectively, and a water pipe for draining is installed at the outlet of each water storage tank 1, two One end of the water pipe far away from the water storage tank 1 is equipped with a spring coil spring water pipe 10 through a three-way interface, and a water outlet 17 is installed at the end of the spring coil spring water pipe 10 away from the water pipe, and a first electromagnetic valve 4 is installed on one of the water pipes. The second solenoid valve 6 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com