Yoghurt stabilizer containing flaxseed gum and application thereof in preparation of yoghurt

A technology of linseed gum and stabilizer, applied in dairy products, yogurt preparation, yogurt stabilizer field, can solve the problems of low viscosity and rough texture of yogurt, achieve strong water binding ability, delicate taste, and improve texture Effect of State and Viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

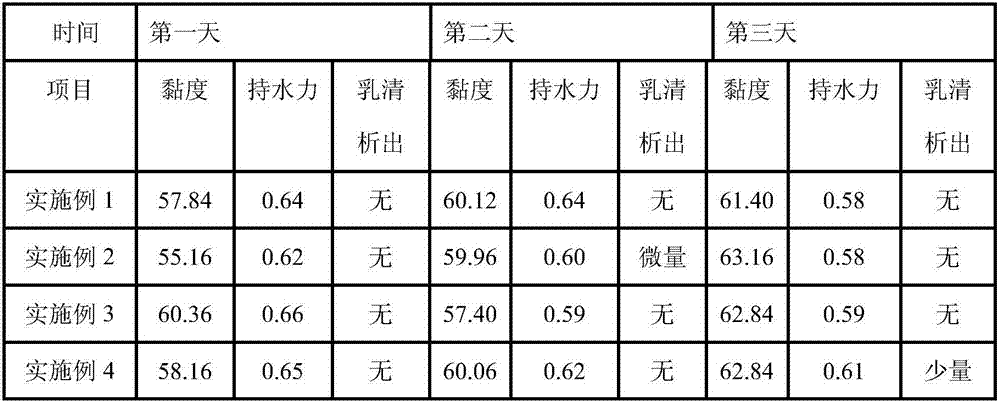

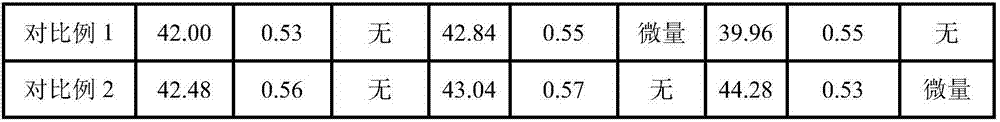

Embodiment 1

[0028] A yoghurt stabilizer comprises the following raw materials compounded and mixed uniformly, and calculated by weight percentage, it contains: 2% of linseed gum, 18% of pectin and 80% of modified starch. The yoghurt prepared by the above yoghurt stabilizer is prepared from the following raw materials in percentage by weight: 0.5% of yoghurt stabilizer, 6% of white sugar, 0.005% of fermentation bacteria, 9% of milk powder and 84.5% of water.

[0029] (1) Dissolution: Weigh 3.0g of yogurt stabilizer, 36g of white sugar, and 54g of milk powder, and add 507g of water to a constant temperature water bath at 70°C to fully dissolve to obtain a mixed solution;

[0030] (2) Homogenization: the mixed solution obtained in step (1) is homogenized under a pressure of 20MPa;

[0031] (3) Sterilization and cooling: heat the homogenized milk in step (2) at 95°C for 300s, and rapidly cool it to 45°C;

[0032] (4) Add strains: weigh 0.05g of bacterial powder, dissolve in 1mL of sterile wa...

Embodiment 2

[0036] A yoghurt stabilizer comprises the following raw materials compounded and mixed uniformly, and calculated by weight percentage, it contains: 3.0% of linseed gum, 8.8% of pectin, and 88.2% of modified starch. The yogurt prepared by the above-mentioned yogurt stabilizer is prepared from the following raw materials in percentage by weight: 0.68% of yogurt stabilizer, 7% of white sugar, 0.005% of fermented bacteria, 9% of milk powder, and 83.3% of water.

[0037] (1) Dissolution: Weigh 4.08g of yogurt stabilizer, 42g of white sugar, and 54g of milk powder, and add 499.8g of water to a constant temperature water bath at 70°C to fully dissolve to obtain a mixed solution;

[0038] (2) Homogenization: the mixed solution obtained in step (1) is homogenized under a pressure of 18MPa;

[0039] (3) Sterilization and cooling: heat the homogenized milk in step (2) at 95°C for 300s, and rapidly cool it to 45°C;

[0040] (4) Add strains: weigh 0.05g of bacterial powder, dissolve in 1m...

Embodiment 3

[0044] A yoghurt stabilizer is compounded and evenly mixed from the following raw materials, and calculated by weight percentage, it contains: 4.55% of linseed gum, 4.55% of pectin and 90.90% of modified starch. The yoghurt prepared by the yoghurt stabilizer is prepared from the following raw materials in percentage by weight: 0.88% of the yoghurt stabilizer, 5% of white sugar, 0.005% of fermented bacteria, 85% of fresh milk and 9.1% of water.

[0045] (1) Dissolution: Weigh 5.28g of yogurt stabilizer, 30g of white sugar, 510g of fresh milk, and 54.6g of water and fully dissolve in a constant temperature water bath at 60°C to obtain a mixed solution;

[0046] (2) Homogenization: the mixed solution obtained in step (1) is homogenized under a pressure of 22MPa;

[0047] (3) Sterilization and cooling: heat the homogenized milk in step (2) at 95°C for 300s, and rapidly cool it to 35°C;

[0048] (4) Add strains: weigh 0.05g of bacterial powder, dissolve in 1mL of sterile water, ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com