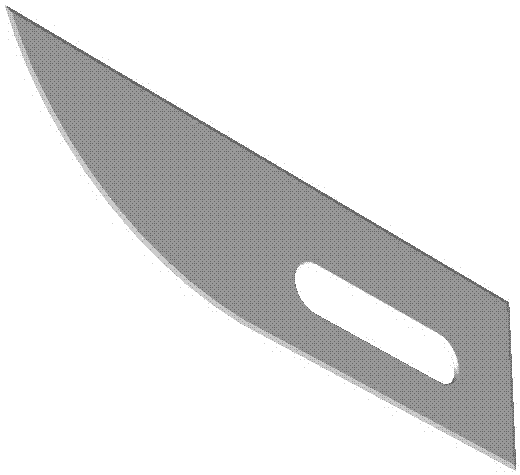

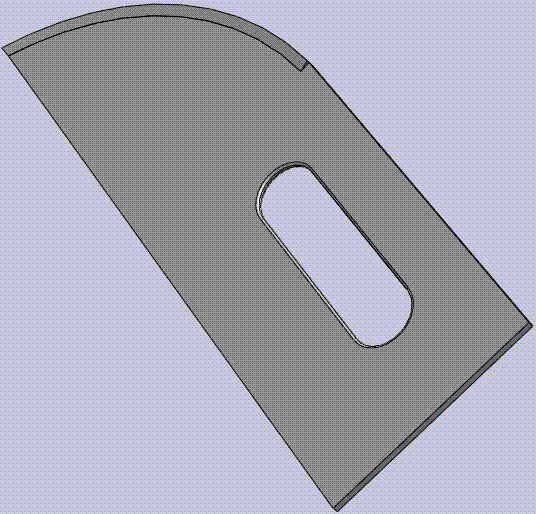

Nano-ceramic scalpel cutting edge sharpening technology and equipment

A scalpel and sharpening technology, which is applied in the field of medical devices, can solve the problems of low toughness, low yield, and easy edge chipping, etc., and achieve the effect of reducing manufacturing costs and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The above-mentioned ELID grinding process and equipment for manufacturing nano-ceramic scalpels is a typical and commonly used method. During specific implementation, some processes can be combined to improve efficiency and save man-hours. The following process flow is for reference:

[0068] 1. Coarsely grind the two sides of the nano-ceramic scalpel and reduce the thickness to 0.8mm. .

[0069] 2. Roughly and finely ground the cutting edge of the nano-ceramic scalpel, one side is qualified.

[0070] 3. Turn over the rough and finely ground nano-ceramic scalpel edge, and the other side is qualified.

[0071] 4. Fine grinding and ultra-precision grinding of both sides of the nano-ceramic scalpel, reducing the thickness to 0.3mm.

[0072] 5. Polished nano-ceramic scalpel with blunt sharp edge.

[0073] 6. Testing and packing.

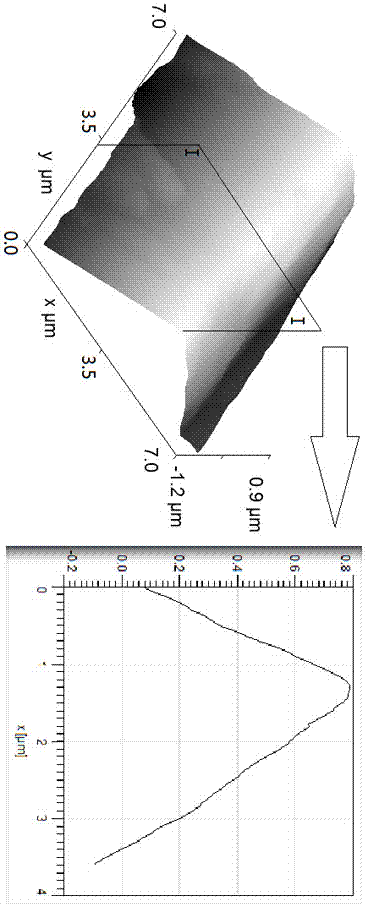

[0074] The surface roughness and cutting edge radius of the nano-ceramic scalpel manufactured by the above-mentioned ELID grinding process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com