High-temperature wear-resisting coating, female die and preparation method of female die

A high-temperature wear-resistant and coating technology, used in coatings, metal material coating processes, ion implantation plating, etc., can solve the problems of poor high temperature resistance and short life of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

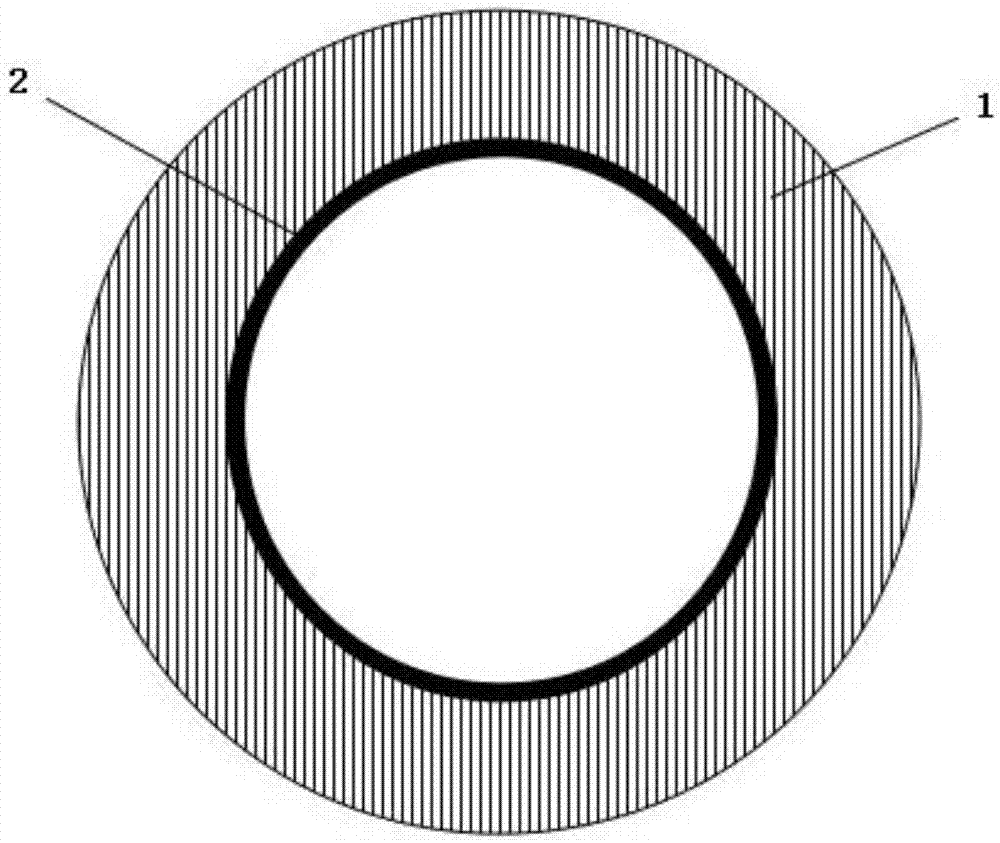

[0033] The present invention also provides a method for preparing a die, comprising:

[0034] Step 1: pretreating the surface of the matrix on the inner wall of the die;

[0035] Step 2: Etching and activating the surface of the inner wall substrate of the concave mold after pretreatment obtained in Step 1;

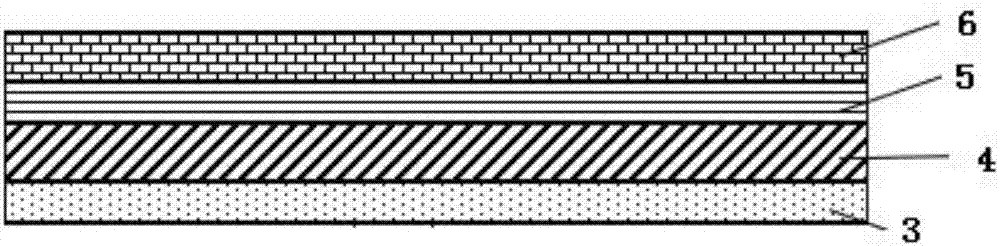

[0036] Step 3: Depositing a Cr bonding layer on the surface of the matrix inner wall of the concave mold after the etching activation treatment obtained in Step 2;

[0037] Step 4: Depositing a CrN transition layer on the surface of the Cr bonding layer obtained in Step 3;

[0038] Step 5: Depositing an AlCrN transition layer on the surface of the CrN transition layer obtained in step 4;

[0039] Step 6: Depositing an AlTiCr(Y)N coating on the surface of the AlCrN transition layer obtained in Step 5 to obtain a concave mold with a high-temperature-resistant and wear-resistant coating deposited on the inner wall.

[0040]According to the present invention, the surface o...

Embodiment 1

[0050] (1) Polish the inner wall of the concave mold made of 3Cr2W8V material to a roughness of less than 0.4 μm, put it into the pre-treatment cleaning line for cleaning, remove the oil stains, polishing wax and adsorbed particles on the surface of the concave mold, preheat after rapid drying After degassing, put it into the coating vacuum chamber, and pump the vacuum to less than 5.0×10 -3 Pa.

[0051] (2) Turn on the heating in the vacuum chamber, the workpiece reaches 440°C, and the backside is vacuumed to less than 5.0×10 -3 After Pa, continue to keep warm for 80 minutes, then pass argon gas into the coating chamber, control the pressure at 1.0Pa, apply a -200V pulse bias voltage on the workpiece; turn on the ion source, adjust the current to 3.5A, and use argon plasma to treat the matrix surface of the die. Bombard cleaning for 65 minutes to clean and activate the coating surface. Then adjust the pressure at 0.45Pa, turn on the Cr arc target, target current 72A, apply ...

Embodiment 2

[0057] (1) Polish the inner wall of the concave mold made of 4Cr3Mo2WMnVNb material to a roughness of less than 0.4μm, put it into the pre-treatment cleaning line for cleaning, remove the oil, polishing wax and adsorbed particles on the surface of the concave mold, preheat after rapid drying After degassing, put it into the coating vacuum chamber, and pump the vacuum to less than 5.0×10 -3 Pa.

[0058] (2) Turn on the heating in the vacuum chamber, the workpiece reaches 450°C, and the backside is vacuumed to less than 5.0×10 -3 After Pa, continue to keep warm for 90min. Then pass argon gas into the coating chamber, control the pressure at 1.1Pa, and apply a -200V pulse bias voltage on the workpiece; turn on the ion source, adjust the current to 4A, and use argon plasma to bombard and clean the matrix surface of the die for 75 minutes to clean and activate the coating surface. Then the pressure was adjusted to 0.5Pa, the Cr arc target was turned on, the target current was 75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com