Copper foil electrolyte, copper foil production method and copper foil electrolysis equipment

A technology of electrolysis equipment and production methods, applied in the direction of electrolysis, electroforming, etc., can solve problems such as infirmity, chemical corrosion, and weak bonding, and achieve the effects of reducing production costs, improving production efficiency, and avoiding surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

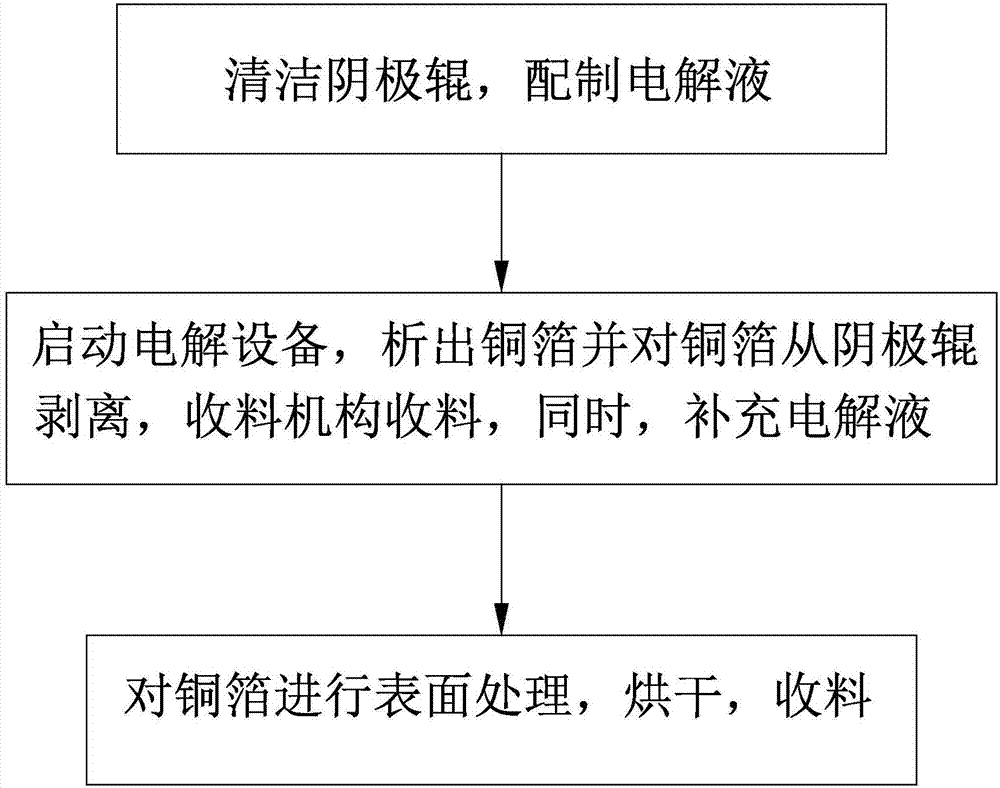

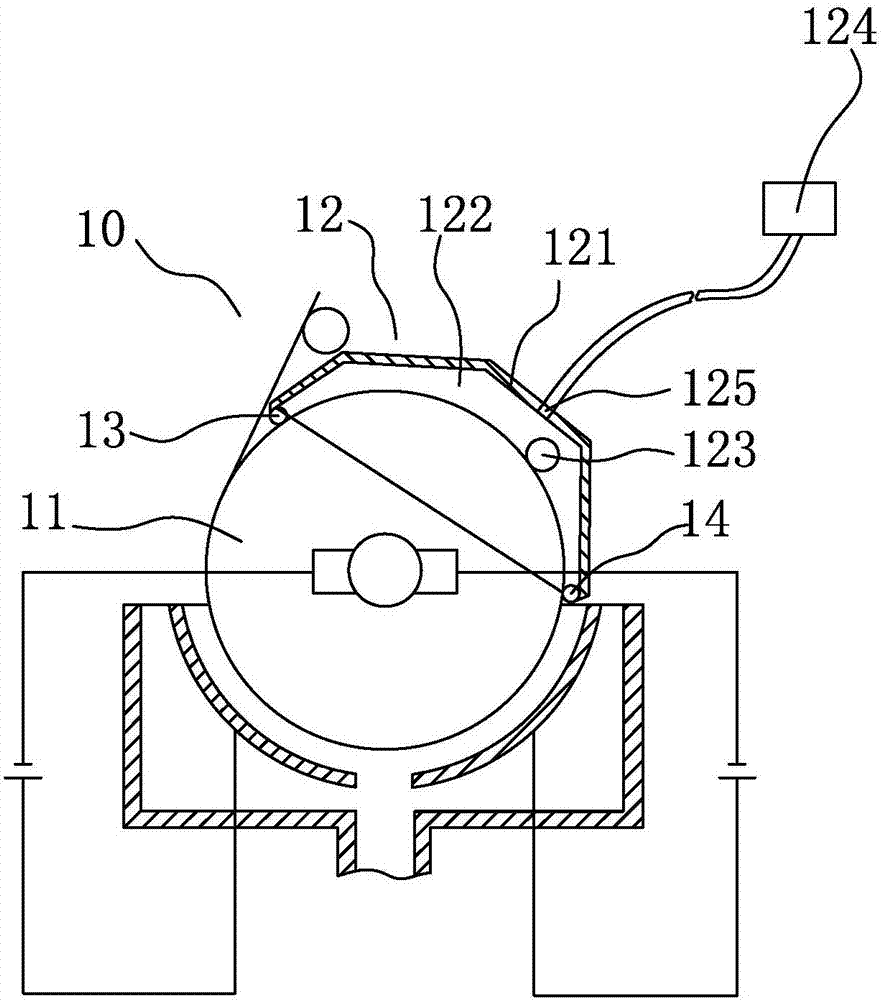

Method used

Image

Examples

Embodiment Construction

[0035] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

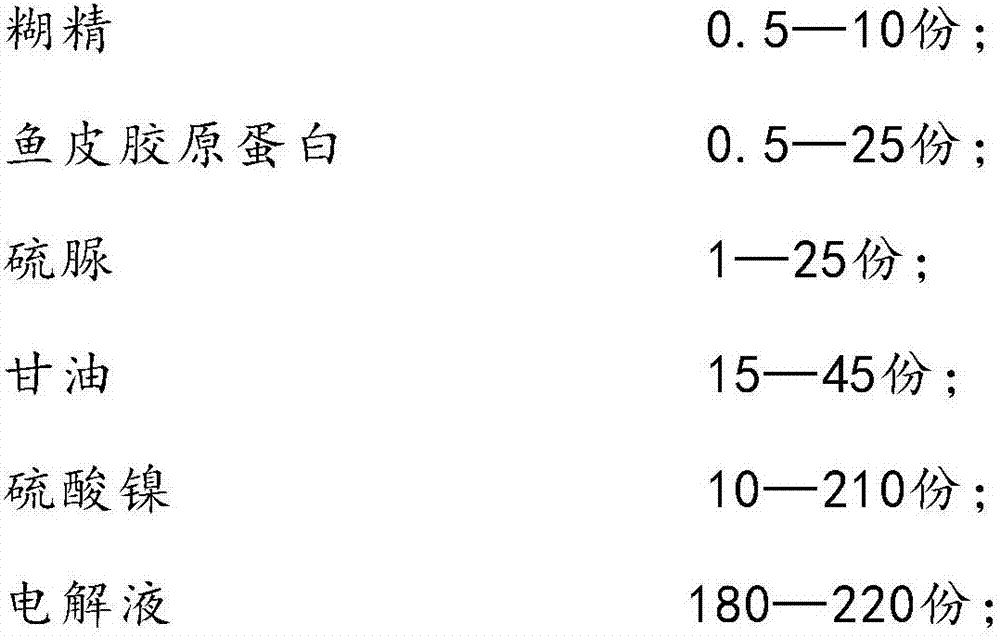

[0036] A copper foil electrolyte, comprising the following composition by weight:

[0037]

[0038]

[0039] Wherein, dextrin, fish skin collagen, thiourea, glycerin, and nickel sulfate are dissolved in the electrolyte, so that the concentration of each component of the electrolyte is:

[0040]

[0041] Among them, the concentration of sulfuric acid in the electrolyte is 60-110g / L, and the concentration of copper ions is 60-90g / L.

[0042] Preferably, a copper foil electrolyte comprises the following composition by weight:

[0043]

[0044] Wherein, dextrin, fish skin collagen, thiourea, glycerin, and nickel sulfate are dissolved in the electrolyte, so that the concentration of each component of the electrolyte is:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com