A magneto-rheological torsional vibration damper for an engine

A torsional vibration damper and magneto-rheological technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as shortened service life, unstable power supply, and increased energy loss, and achieve Adaptive damping force, relatively low cost, and the effect of adjusting the damping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

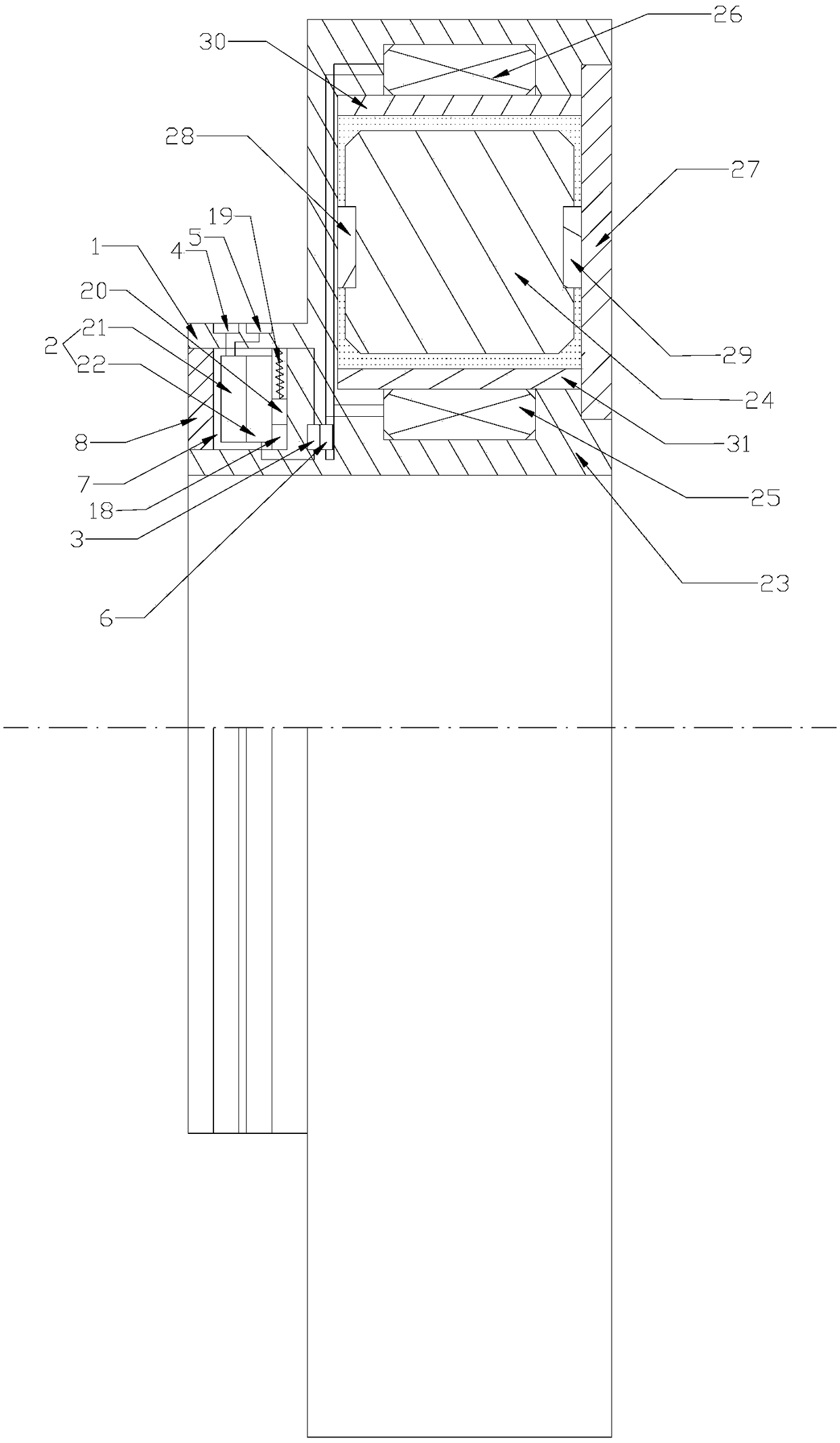

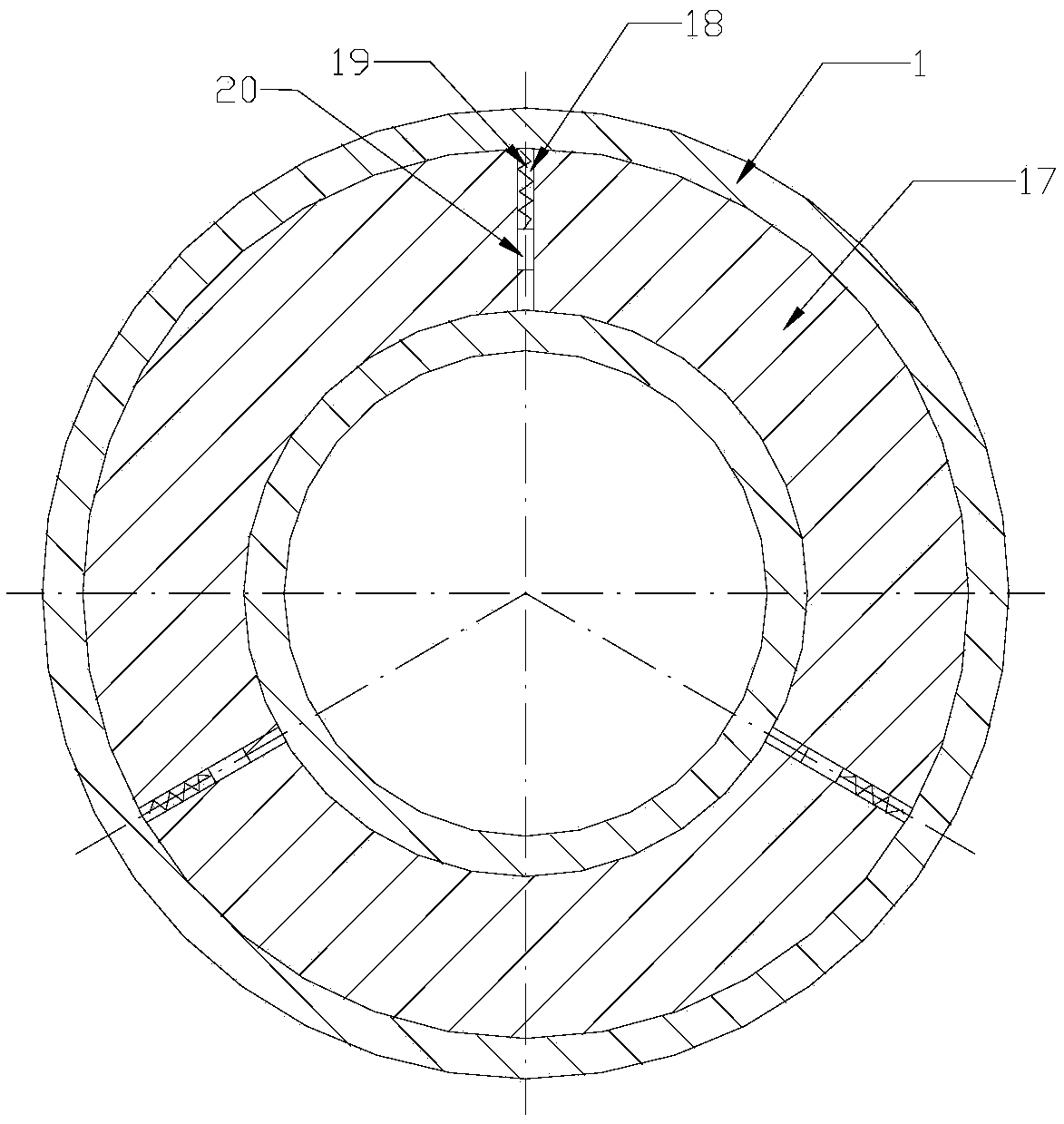

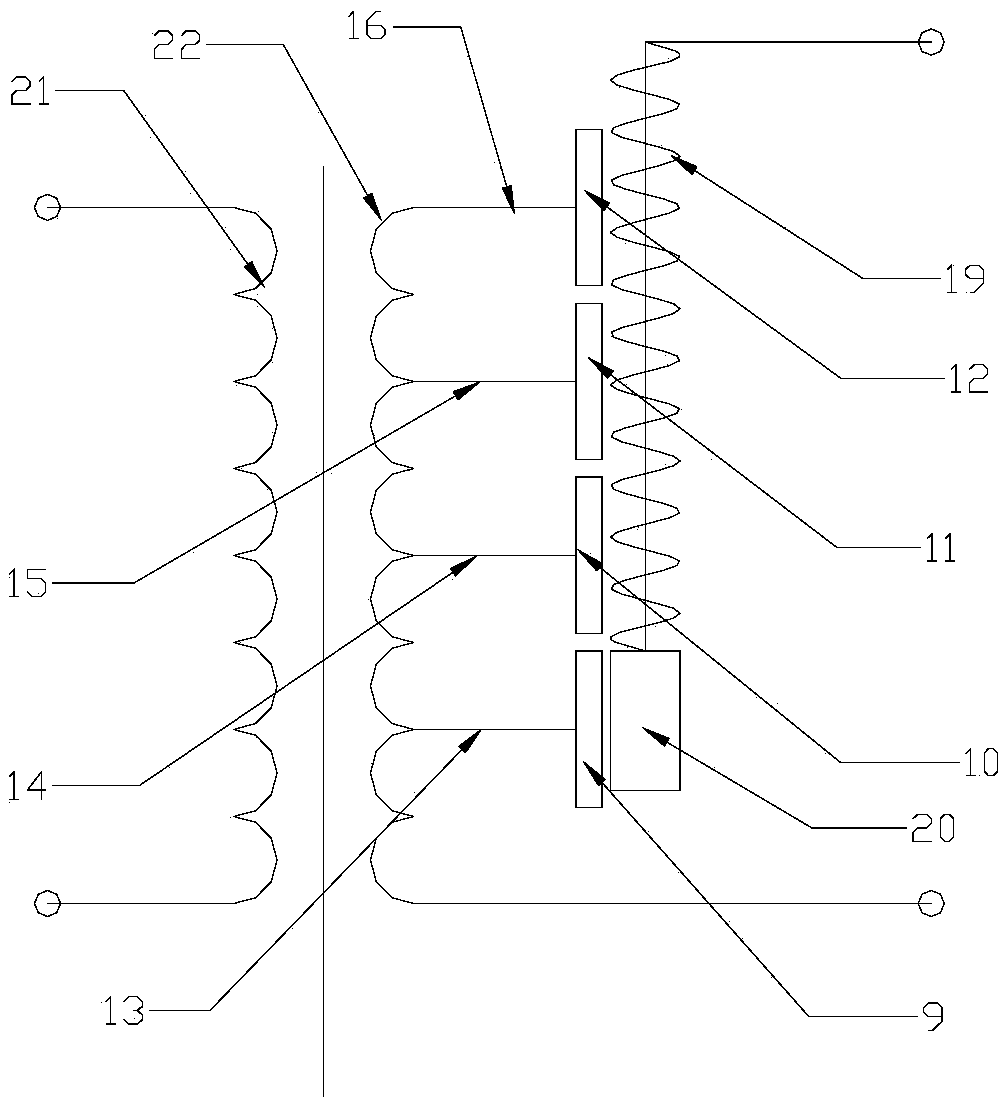

[0015]Embodiment 1: As shown in the figure, an engine magneto-rheological torsional vibration damper includes a main structure of the magnetorheological torsional vibration damper, and the engine magnetorheological torsional vibration damper also includes an adaptive voltage regulation module, The adaptive voltage regulation module includes a first annular casing 1, a control transformer 2, a voltage comparator 3, a first collector ring 4, a second collector ring 5, an AC-DC converter 6 and an adaptive brush assembly, the voltage The comparator 3 has a first input terminal, a second input terminal, a third input terminal, a fourth input terminal and an output terminal, and the first slip ring 4 and the second slip ring 5 are arranged on the first annular casing 1 respectively. On the outer wall, the first annular housing 1 is provided with a first annular cavity 7 with an open left end, and the opening of the first annular cavity 7 is provided with a first cover plate 8 coverin...

Embodiment 2

[0016] Embodiment 2: As shown in the figure, an engine magneto-rheological torsional vibration damper includes a main structure of the magnetorheological torsional vibration damper, and the engine magnetorheological torsional vibration damper also includes an adaptive voltage regulation module, The adaptive voltage regulation module includes a first annular casing 1, a control transformer 2, a voltage comparator 3, a first collector ring 4, a second collector ring 5, an AC-DC converter 6 and an adaptive brush assembly, the voltage The comparator 3 has a first input terminal, a second input terminal, a third input terminal, a fourth input terminal and an output terminal, and the first slip ring 4 and the second slip ring 5 are arranged on the first annular casing 1 respectively. On the outer wall, the first annular housing 1 is provided with a first annular cavity 7 with an open left end, and the opening of the first annular cavity 7 is provided with a first cover plate 8 coveri...

Embodiment 3

[0018] Embodiment 3: As shown in the figure, an engine magneto-rheological torsional vibration damper includes a main structure of the magnetorheological torsional vibration damper, and the engine magnetorheological torsional vibration damper also includes an adaptive voltage regulation module, The adaptive voltage regulation module includes a first annular casing 1, a control transformer 2, a voltage comparator 3, a first collector ring 4, a second collector ring 5, an AC-DC converter 6 and an adaptive brush assembly, the voltage The comparator 3 has a first input terminal, a second input terminal, a third input terminal, a fourth input terminal and an output terminal, and the first slip ring 4 and the second slip ring 5 are arranged on the first annular casing 1 respectively. On the outer wall, the first annular housing 1 is provided with a first annular cavity 7 with an open left end, and the opening of the first annular cavity 7 is provided with a first cover plate 8 coveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com