Microalloyed steel mechanical property prediction method based on global additive model

A technology of alloy steel mechanics and micro-alloy steel, which is applied in metal rolling, dynamic trees, instruments, etc., can solve the problems of inability to guarantee extrapolation ability, inconvenient research on the influence of composition, and high accuracy of training samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] The following takes hot rolling Nb-containing microalloy steel as an example to carry out mechanical property prediction modeling.

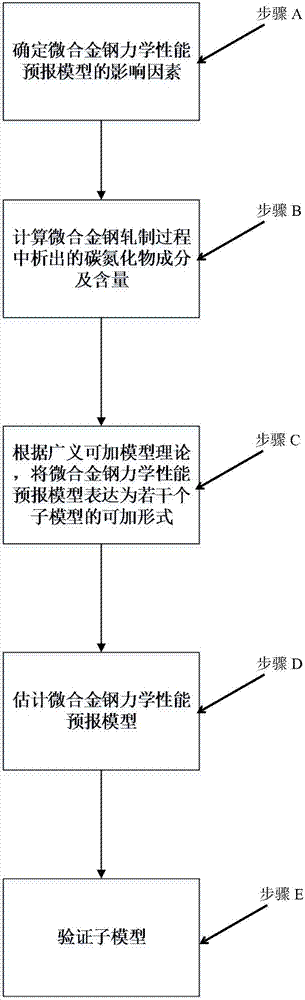

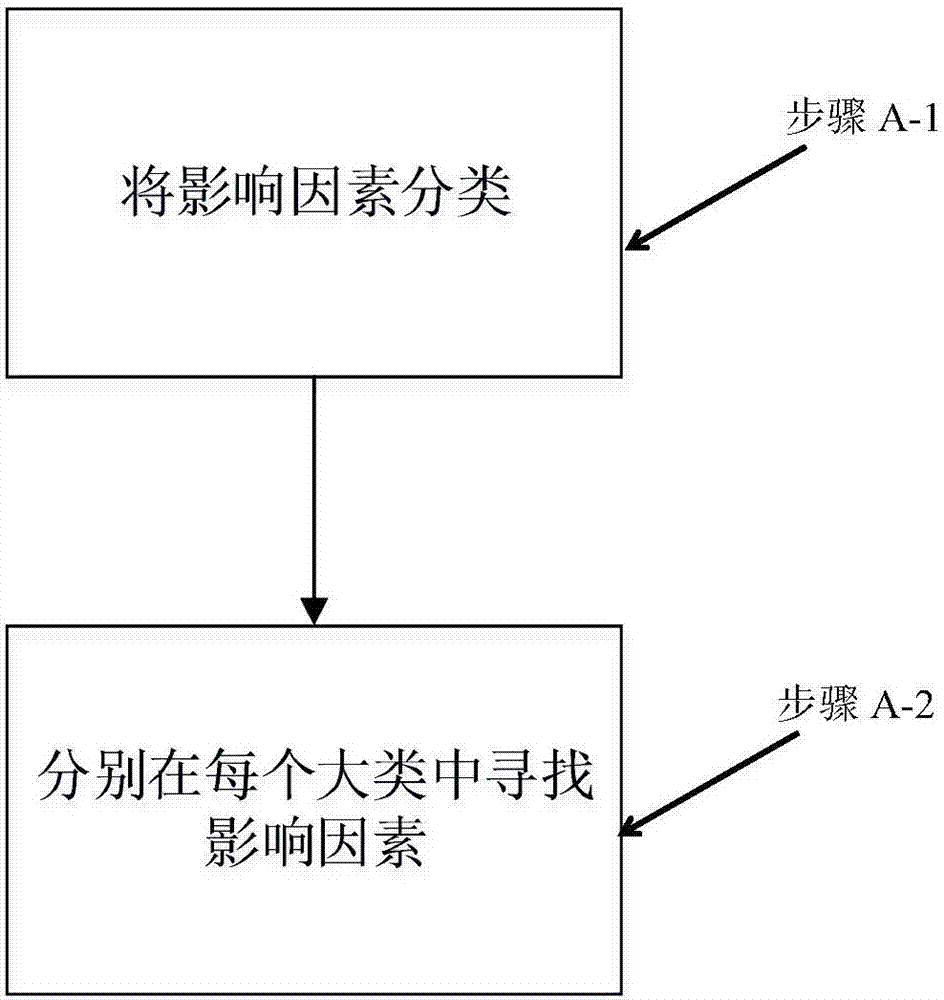

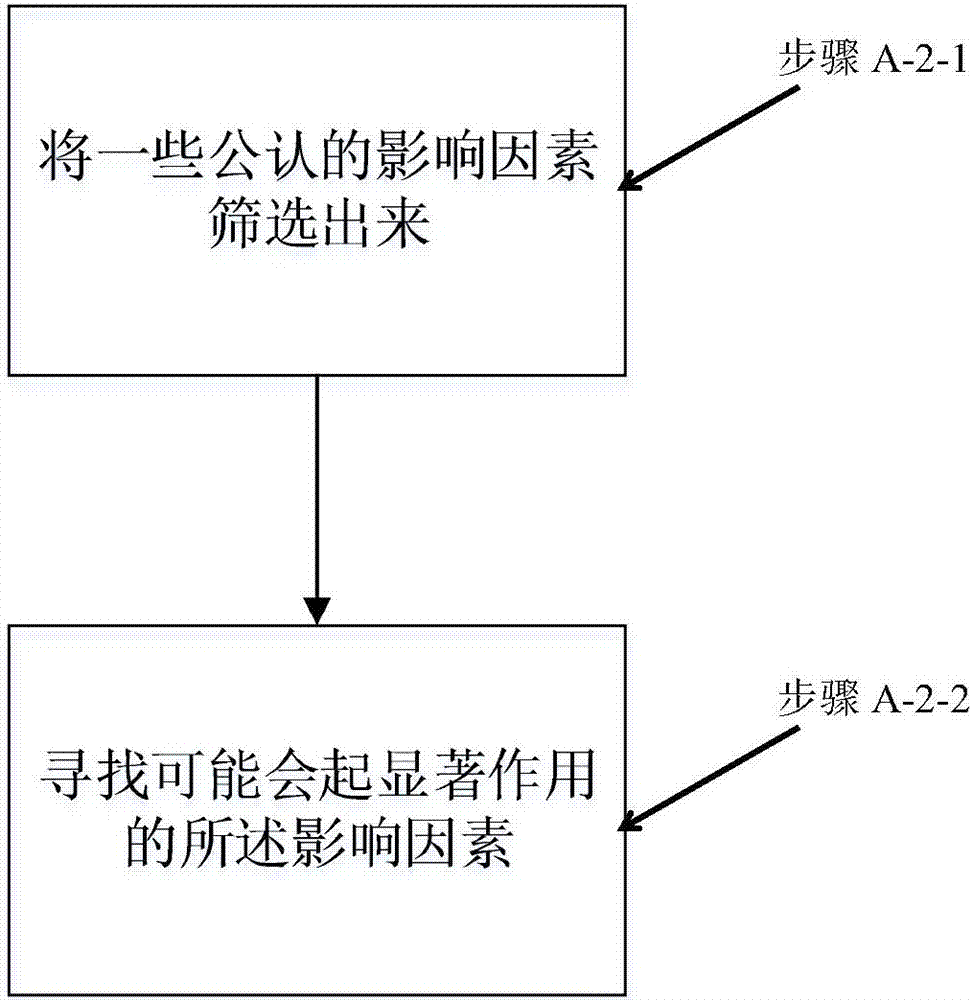

[0073] Such as figure 1 , figure 2 and image 3 As shown, step A: Determine the influencing factors of the mechanical property prediction model of the microalloyed steel, and proceed to step B.

[0074] Conduct industrial big data analysis on mechanical property prediction process parameters to find suitable influencing factors. Due to the diversity and complexity of the influencing factors, the process of finding the influencing factors is a process of repeated correction. Through analysis methods such as random forest and Bayesian method, combined with metallurgical mechanism and prior knowledge, the chemical components such as carbon, silicon, manganese, phosphorus and niobium in strip steel, as well as the furnace temperature TF, rough rolling temperature TR, finishing temperature, etc., were selected. The rolling process paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com