Jellyfish driving infrasonic wave acoustic generator

A technology of infrasonic wave and sound generator, which is applied in the field of infrasonic wave sound generator, which can solve the problems of low cost-effectiveness and low efficiency of infrasonic sound generation, and achieve the effects of improving power tolerance, good water resistance, and high electroacoustic conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

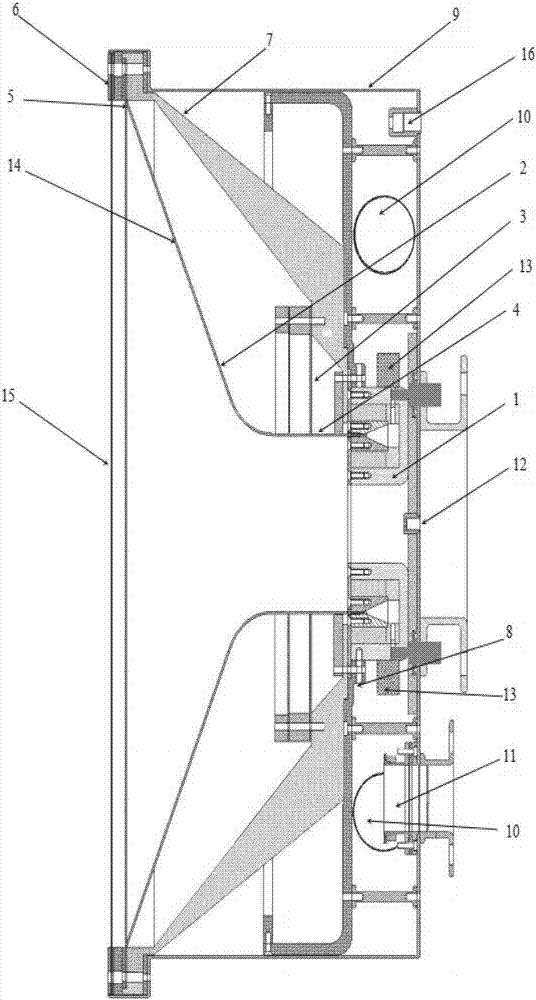

[0038]A pot horn type infrasonic sound generator for repelling jellyfish, such as figure 1 As shown, it includes electric driver 1, water-resistant diaphragm 2, elastic wave 3, vibration coil 4, water-resistant folding ring 5, watertight pressure ring 6, driver basin frame 7, terminal post 8, water-resistant and pressure-resistant cavity 9, pressure equalization Oil bag 10, pressure equalizing oil nozzle 11, oil injection nozzle 12, heat exchanger 13, waterproof biofilm 14, anti-filing net 15 and watertight connector 16, electric driver 1 is located at the bottom of the water-resistant and pressure-resistant cavity 9. The installation is fixed, the heat exchanger 13 is installed on the outside of the electric driver 1, the vibration coil 4 is installed in the middle of the magnetic gap of the electric driver 1, the vibration coil 4 is bonded with the water-resistant diaphragm 2 and the elastic wave 3, and the water-resistant diaphragm 2 It is seamlessly connected with the wate...

Embodiment 2

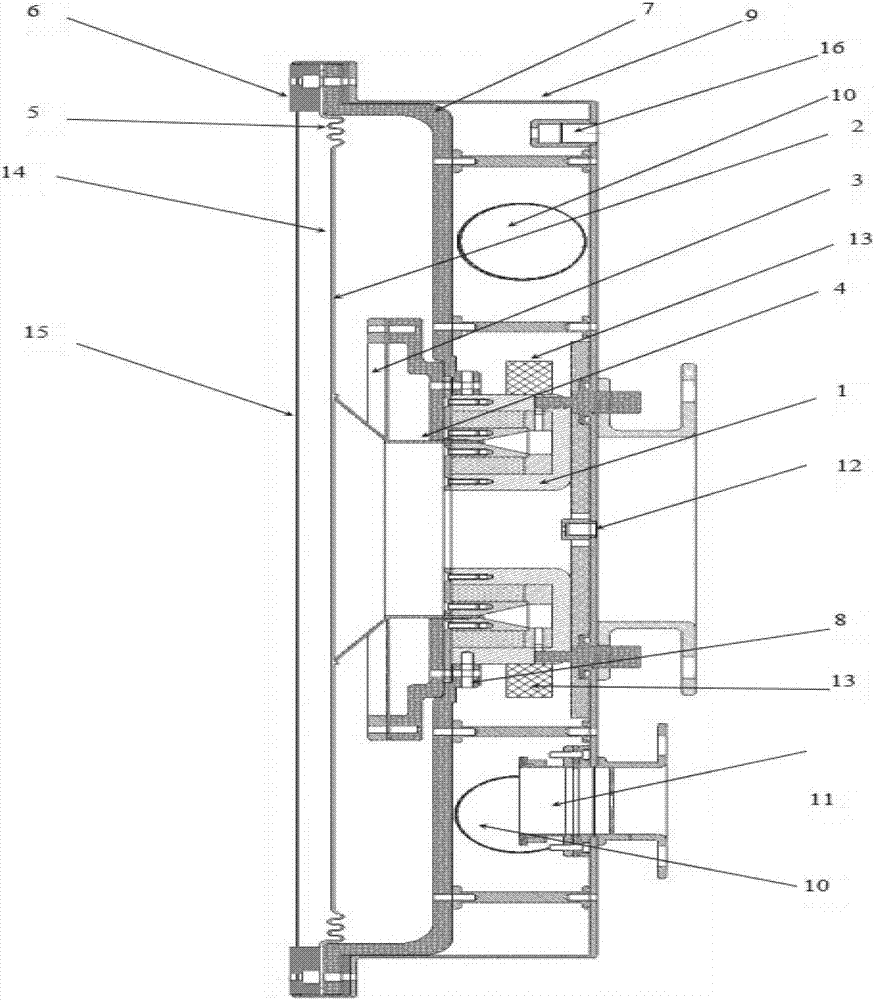

[0040] A disc-type plate type infrasonic sounder for repelling jellyfish, different from Embodiment 1 in that the water-resistant and pressure-resistant cavity is shallow, there is no basin frame, and the water-resistant diaphragm is flat-plate type, such as figure 2 As shown, it includes an electric driver 1, a water-resistant diaphragm 2, an elastic wave 3, a vibration coil 4, a water-resistant fold ring 5, a water-tight pressure ring 6, a terminal post 8, a water-resistant and pressure-resistant cavity 9, a pressure equalizing oil bag 10, and an equalizing Oil pressure nozzle 11, oil injection nozzle 12, heat exchanger 13, waterproof biofilm 14, anti-filing net 15 and watertight connector 16, electric drive 1 is located at the bottom of the water and pressure resistant cavity 9 and is suspended and fixed in the center. A heat exchanger 13 is installed on the outside of the driver 1, and a vibration coil 4 is installed in the middle of the magnetic gap of the electric driver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com