Device and method for treating waste gas of quenched and tempered viscosity-adjusting steam jet pump

A technology for conditioning, viscosity, and treatment devices, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as environmental pollution, and achieve the effects of improving the environment, reducing odor, and reducing the content of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below through specific examples, but the present invention is not limited only to the following examples.

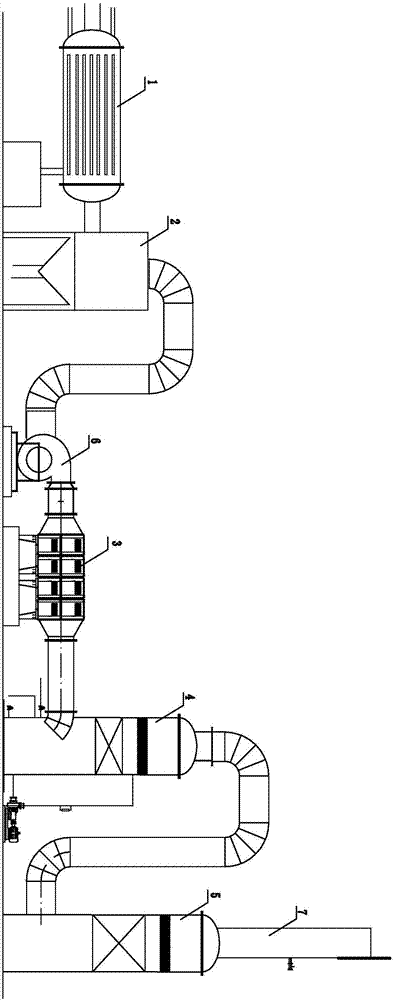

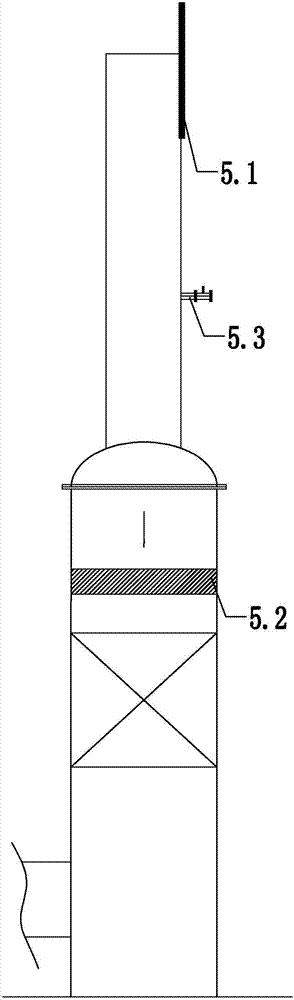

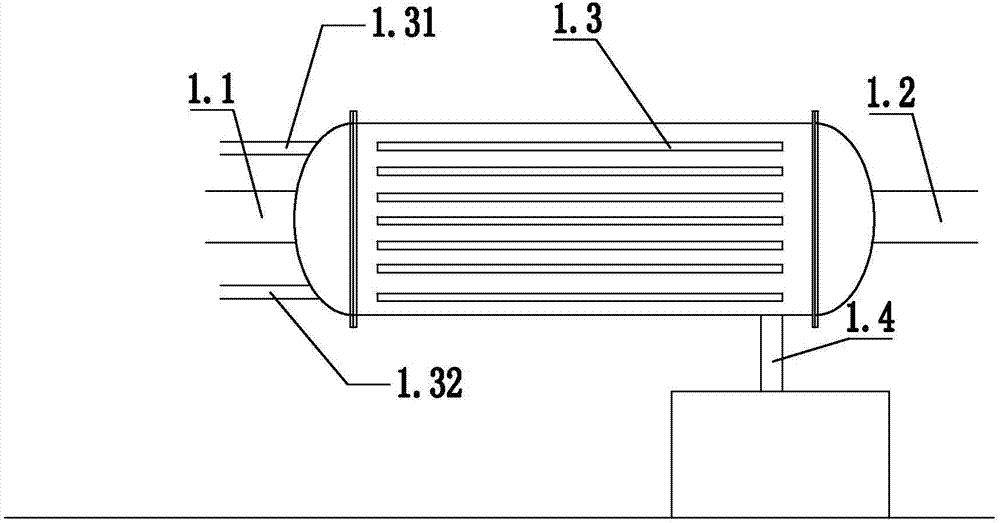

[0025] as attached figure 1 Shown: a treatment device for the waste gas of a steam jet pump for conditioning, tempering and viscosity-adjusting of the present invention, the device includes a condenser 1 communicated with the exhaust gas discharge pipe, a cooling tank 2 communicated with the condenser, and an integrated dewatering tank communicated with the cooling tank Odor device 3, the ozone reduction tower 4 that is communicated with integrated deodorization device, the activated carbon adsorption device 5 that is communicated with ozone reduction tower; Fan 6 is arranged between described cooling tank and integrated deodorization device, and described activated carbon An exhaust pipe 7 is arranged on the adsorption device.

[0026] With the above structure, the exhaust gas at 80-90°C generated from the tempered, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com