Two-phase mixing reactor and applications thereof

A mixed reactor and reactor technology, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, refining with alkaline aqueous solution, etc., can solve low mass transfer coefficient, fiber filament pollution, mass transfer Efficiency reduction and other problems, to achieve the effect of enhanced mass transfer performance, strong pressure resistance, and easy sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

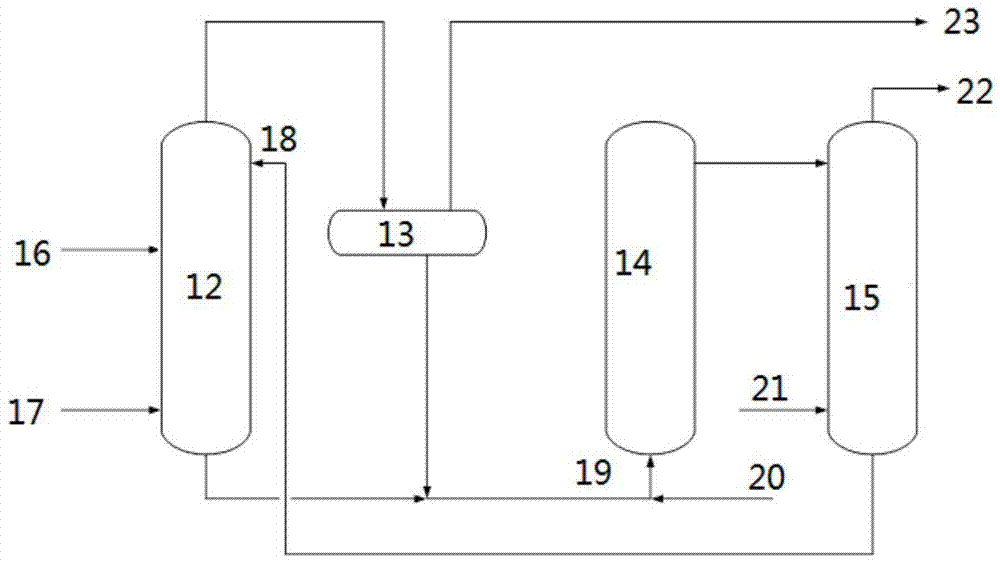

[0088] In this embodiment, the two-phase mixed reactor described in the present invention is used to desulfurize light hydrocarbons, specifically as follows:

[0089] The liquefied petroleum gas containing mercaptan and the alkali solution contact in the alkali cleaning unit, and the mercaptan reacts with the NaOH in the alkali solution to form sodium mercaptide which is dissolved in the alkali solution. The liquefied gas discharged from the alkaline cleaning unit enters the settling unit and is separated from part of the alkali liquor entrained to complete the purpose of sweetening. The lye discharged from the settling unit enters the oxidation regeneration unit, and in the packed bubbling bed reactor, the lye reacts with air to convert sodium mercaptide into disulfide. The desulfurized lye discharged from the oxidation regeneration unit enters the back extraction unit, contacts with gasoline, removes the entrained disulfide, and obtains the regenerated lye. The regenerated ...

Embodiment 2

[0100] In this embodiment, the two-phase mixed reactor described in the present invention is used to desulfurize light hydrocarbons, specifically as follows:

[0101] The light hydrocarbon desulfurization method in this embodiment is similar to that in Example 1, and the two-phase mixed reactor also includes 11 groove structures, the difference is:

[0102] The light hydrocarbon in this example is light gasoline, and there is only one two-phase mixed reactor in the alkali washing unit and the stripping unit.

[0103] The selected light gasoline was obtained from Jiujiang Petrochemical, and its hydrocarbon volume percentage composition is shown in Table 2.

[0104] Table 2: Volume percentage composition of light gasoline hydrocarbons

[0105] n-paraffin / % Isoparaffin / % Olefin / % Diene / % C4 2.141 0.978 5.237 0 C5 13.368 41.388 29.821 0.039 C6 0 5.889 1.140 0

[0106] The total amount of acid mercaptans in light gasoline is determine...

Embodiment 3

[0112] In this embodiment, the two-phase mixed reactor described in the present invention is used to desulfurize light hydrocarbons, specifically as follows:

[0113] The method of light hydrocarbon desulfurization in the present embodiment is similar to that in embodiment 2, difference is:

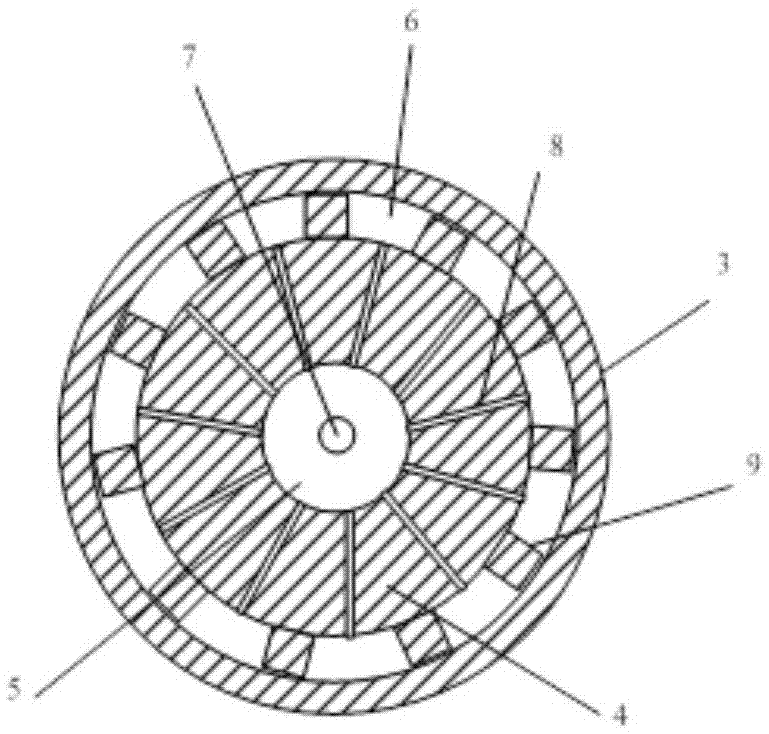

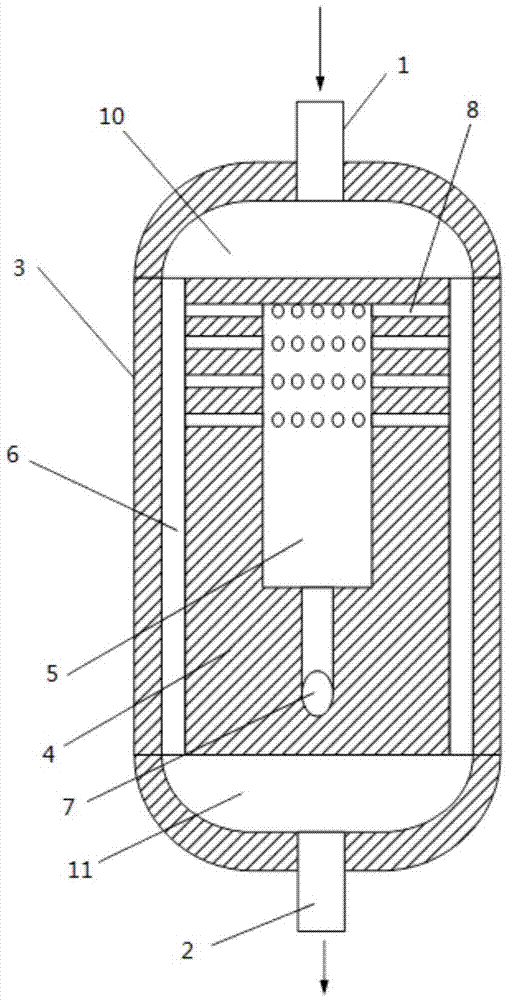

[0114] In the alkaline cleaning unit: according to the flow direction of the lye in the cavity unit, the diameters of the distribution holes are 1mm, 0.7mm and 0.4mm respectively, the depth of the distribution holes is 1mm, and the distance between the centers of two adjacent distribution holes is 27mm. The cross-sectional area of the cavity unit perpendicular to the flow direction of lye is 280mm 2 , the cross-sectional area of the mixing channel perpendicular to the flow direction of sulfur-containing light hydrocarbons is 6mm 2 , the length of the mixing channel is 1000mm. The temperature in the two-phase mixing reactor was 50° C. and the pressure was 1.2 MPa. The superficial f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com