Calcium-magnesium combined desulphurization and denitrification method realizing deep removal of flue gas pollutants

A technology for desulfurization, denitrification, and deep desulfurization, which is applied in separation methods, chemical instruments and methods, and gas treatment, and can solve the problems of calcium desulfurization that is difficult to meet the requirements of ultra-low emissions, high cost, and difficult to apply to large-scale desulfurization. Achieve the effect of not easy to corrode, improve desulfurization efficiency and reduce maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

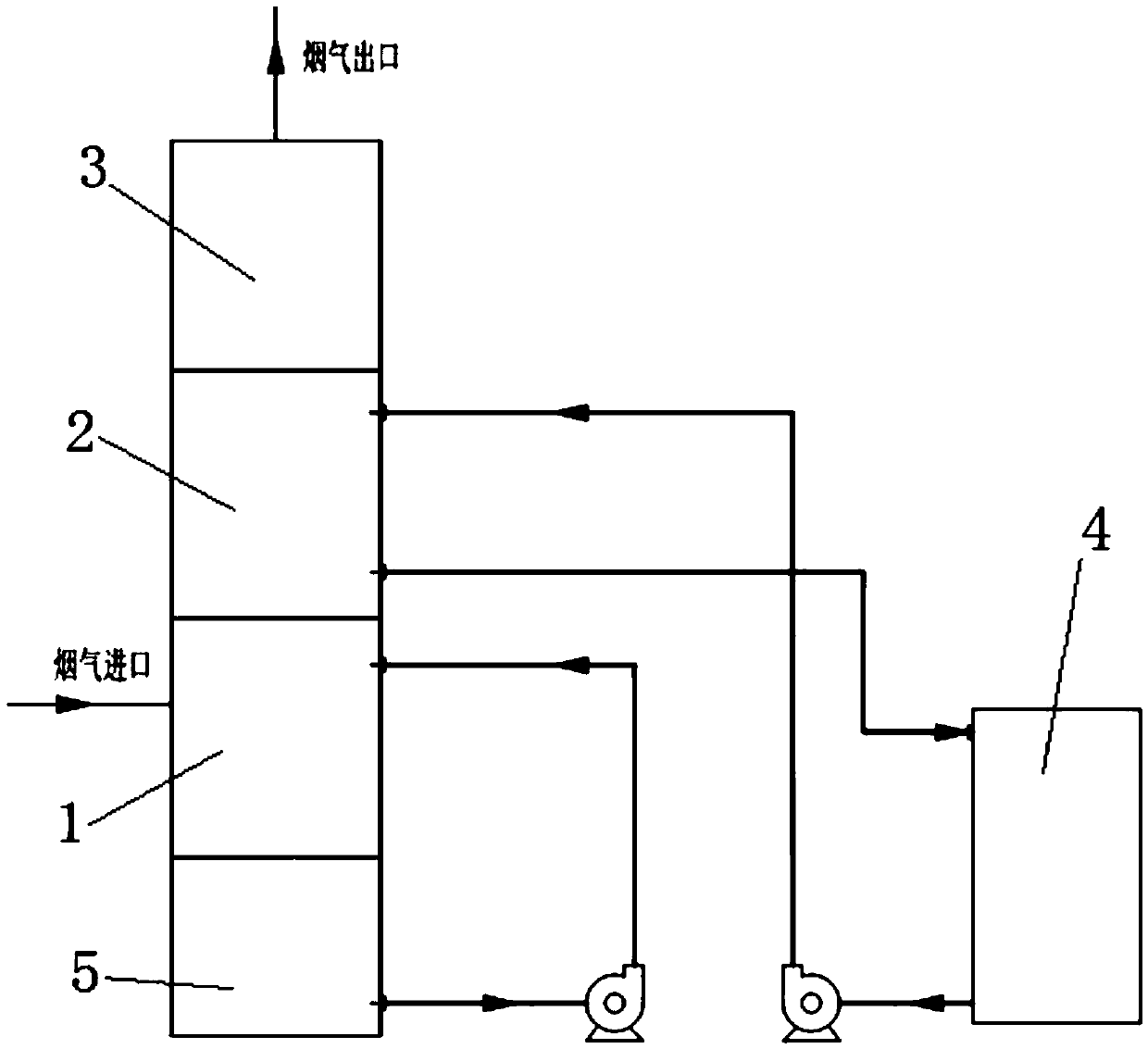

[0030] Such as figure 1 As shown, this embodiment adopts integrated equipment, which are tower kettle area 5, main desulfurization area 1, deep desulfurization area 2 and dust and mist removal area 3 from bottom to top. The solution in the deep desulfurization zone 2 is passed into the desulfurization liquid circulation pool 4, and ammonia water is added to obtain magnesium hydroxide for recycling. The specific steps are as follows:

[0031] (1) The concentration of sulfur dioxide in raw flue gas is 500mg / m 3 , the concentration of nitrogen oxides is 150mg / m 3 , of which nitric oxide 80mg / m 3 , nitrogen dioxide 70mg / m 3 , the flue gas temperature is 180°C; the raw flue gas is 3 The flow rate of / h is discharged into the main desulfurization zone 1; the main desulfurization zone adds a desulfurizer solution with a flow rate of 300L / h, which is prepared by dissolving lime in water, its concentration is 20wt%, and its pH is 6.5. After that, low-sulfur flue gas is obtained, a...

Embodiment 2

[0038] This embodiment adopts integrated equipment, which are dust and mist removal area, deep desulfurization area, main desulfurization area, and tower kettle area from top to bottom. The solution in the deep desulfurization area is passed into the desulfurization liquid circulation pool, and ammonia water is added to obtain magnesium hydroxide for recycling. The specific steps are as follows:

[0039](1) The concentration of sulfur dioxide in raw flue gas is 5000mg / m 3 , the concentration of nitrogen oxides is 450mg / m 3 , of which nitric oxide 250mg / m3, nitrogen dioxide 200mg / m3 3 , the flue gas temperature is 180°C; the raw flue gas is 3 The flow rate of / h is discharged into the main desulfurization area; the main desulfurization area adds a desulfurizer solution with a flow rate of 800L / h, which is prepared by dissolving lime in water, its concentration is 5wt%, and its pH is 5.5. After the reaction , to obtain low-sulfur flue gas, after the reaction, to obtain low-su...

Embodiment 3

[0046] Field test 1: Take the actual flue gas of a coal-fired power plant as the treatment object, and lead it out from the flue for 100m 3 / h of actual flue gas, in which the concentration of sulfur dioxide is 800mg / m 3 , the concentration of nitric oxide is 200mg / m 3 , the concentration of nitrogen dioxide is 180mg / m 3 (ozone injection). Limestone powder is used as the desulfurizer in the main desulfurization area, the solution concentration is about 10%, and the desulfurization liquid-gas ratio is 5L / m 3 , the desulfurization agent in the deep desulfurization area is magnesium oxide, the pH value of the desulfurization liquid is controlled at 7, the concentration of the slurry is 2%, and the desulfurization liquid-gas ratio is 2L / m 3 , and add 1% hydrogen peroxide in the deep desulfurization zone. Using the same steps as in Example (1), desulfurization and denitrification treatment was performed on raw flue gas. Through testing and analysis, it can be concluded that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com