Efficient ultrasonic vibration assisted forming tantalum capacitor pressing device

An ultrasonic vibration and auxiliary molding technology, applied in capacitor parts and other directions, can solve the problems of uneven pressing density distribution, complex pressing device structure, and large labor and material resources, and achieve excellent pressing effect, simple and integrated structure, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

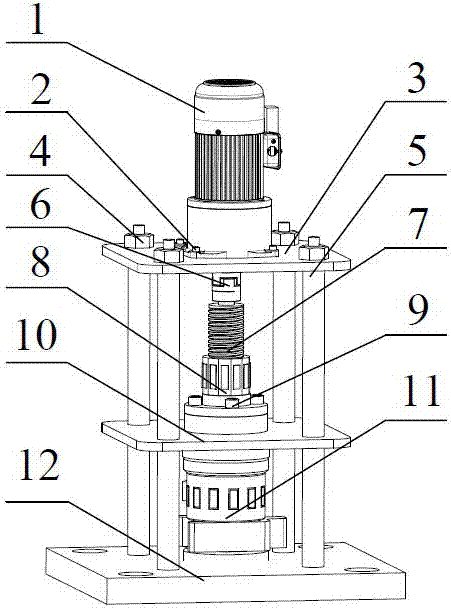

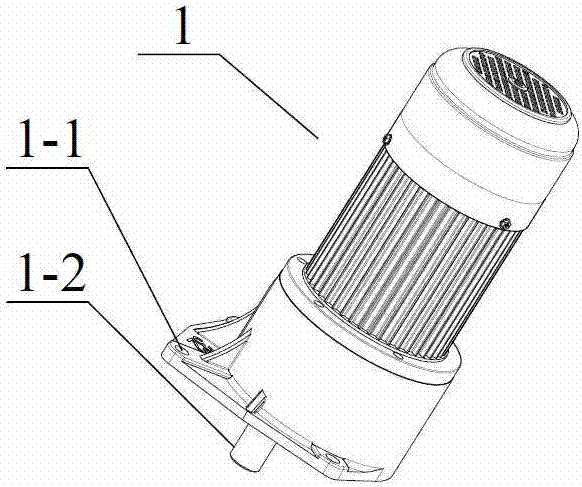

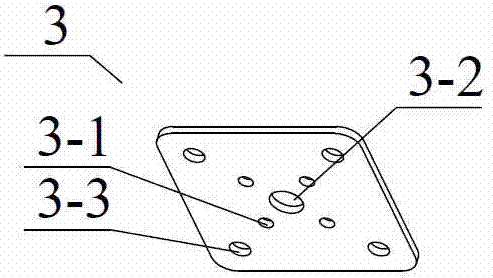

[0030] Specific implementation mode one: combine Figure 1~Figure 17 This embodiment will be described. This implementation mode provides a specific implementation scheme of an efficient ultrasonic vibration-assisted forming tantalum capacitor pressing equipment. The high-efficiency ultrasonic vibration-assisted forming tantalum capacitor pressing equipment includes a motor 1, a fixing bolt 2, a fixing plate 3, a nut 4, a support rod 5, a shaft coupling 6, a lead screw 7, an anti-friction nut 8, a fastening bolt 9. Pressing plate 10, vibrating mold assembly 11 and base 12; the motor 1 is fixed to the fixing plate 3 by screwing the fixing bolt 2 to the fixing plate 3; the nut 4 is threaded to the support rod 5 to realize the fixing plate 3 Fixing with the support rod 5; the coupling 6 connects the motor 1 and the lead screw 7 to realize the transmission of the kinetic energy of the motor 1; the lead screw 7 is threaded with the anti-friction nut 8; the fastening bolt 9 is thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com