Anhydrous oxyhalide tellurite glass and preparation method thereof

An oxyhalotellurite and glass technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problem of not increasing the phonon energy, and achieve the improvement of anti-devitrification ability, enhanced luminescence and laser output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

[0027] Table 1 provides the glass formula of 7 specific examples of the present invention:

[0028] Table 1

[0029]

[0030]

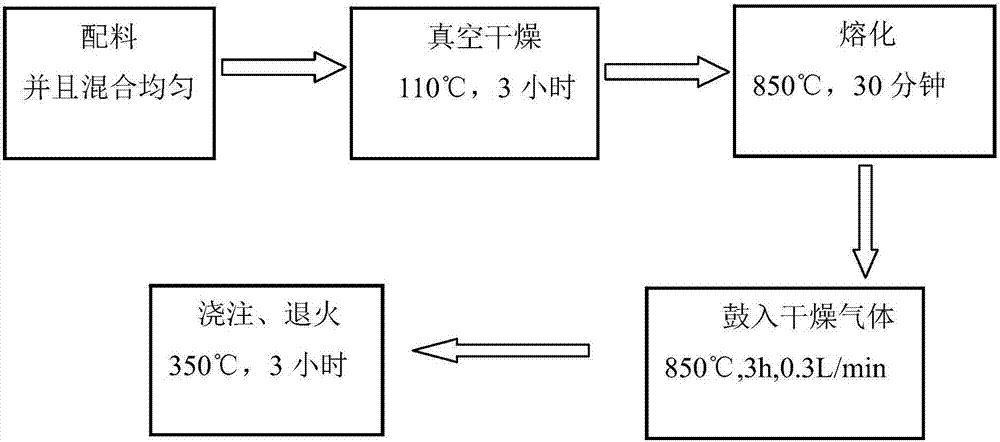

[0031] The present invention provides a kind of anhydrous oxyhalogen tellurate glass, and provides the preparation method of the anhydrous oxyhalogen tellurate glass, refer to figure 1 The preparation process comprises the following steps:

[0032] 1), according to the proportioning relationship of Table 1 Example 1, take the raw materials, add 2% ammonium bifluoride by weight, and mix evenly;

[0033] 2) Dry the mixture in a vacuum oven at 110°C for 3 hours;

[0034] 3) Put the raw material into an alumina crucible and melt it in a furnace at 850°C;

[0035] 4) After the glass is melted, use a quartz tube to feed dry high-purity oxygen into the molten glass, the flow rate of oxygen is 0.5L / min, and the time is 3 hours;

[0036] 5) Pour the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com