Preparation method of environment-friendly paint

An environmentally friendly, water-based polyurethane technology, applied in the field of coating technology, can solve problems such as difficult operation and unfavorable promotion, and achieve the effects of easy operation and control, favorable promotion and reduced dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

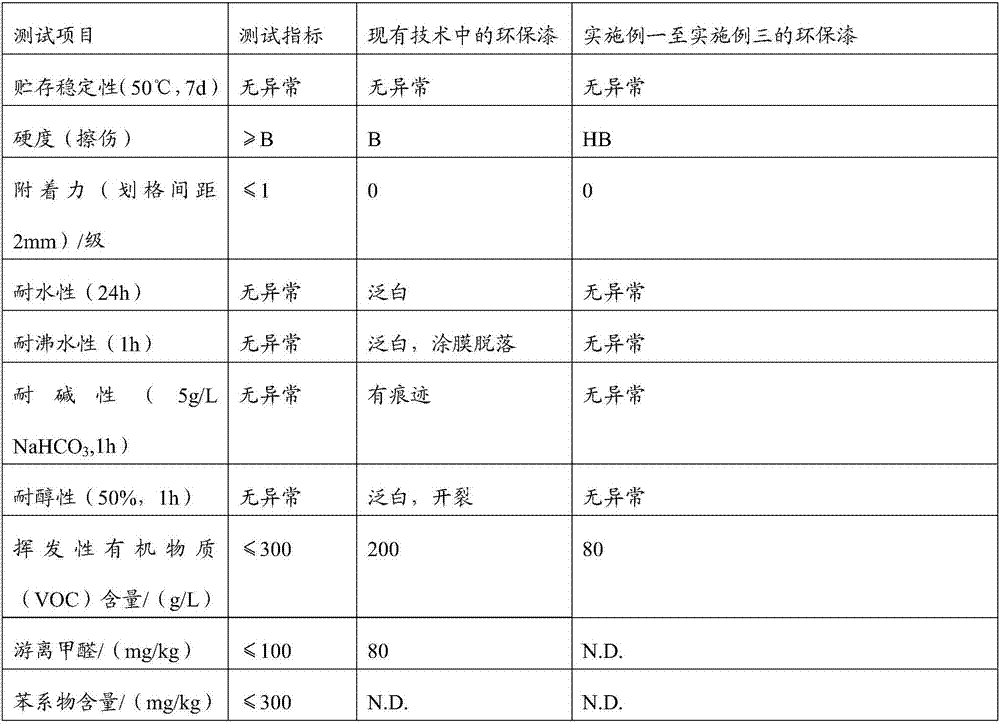

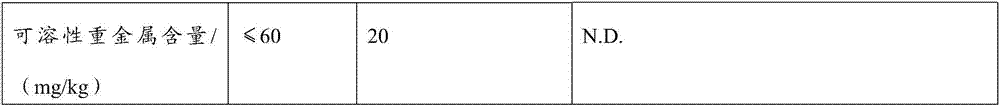

Examples

preparation example Construction

[0017] The invention provides a method for preparing an environmentally friendly paint, which comprises the following raw materials in parts by weight: 20-32 parts of water-based resin, 2-5 parts of dye auxiliaries, 40-65 parts of water, 0.3 parts of LT rheological additives, 0.5-0.7 parts of WT-204 rheological additives and 3-5 parts of film-forming aids, the water-based resin includes water-based polyurethane resin emulsion and water-based alkyd resin, the weight parts of the water-based polyurethane resin emulsion and water-based alkyd resin The ratio is 1:1;

[0018] Weigh the above raw materials in parts by weight, transfer water into the reaction vessel, control the temperature at 40-50°C, add water-based alkyd resin while stirring, control the temperature at 50-60°C, and then add water-based polyurethane resin while stirring For the emulsion, add LT rheological additive, WT-204 rheological additive, film-forming additive and dye additive in sequence while stirring, and ...

Embodiment 1

[0035] A preparation method of an environmentally friendly paint, which comprises the following raw materials in parts by weight: 20 parts of water-based resin, 2 parts of dye auxiliaries, 40 parts of water, 0.3 parts of LT rheological additives, 0.5 parts of WT-204 rheological additives, 3 parts of film-forming aids, the water-based resin includes a water-based polyurethane resin emulsion and a water-based alkyd resin, and the weight ratio of the water-based polyurethane resin emulsion to the water-based alkyd resin is 1:1. The film-forming aid is a mixture of diethylene glycol butyl ether and dipropylene glycol butyl ether, and the weight ratio of diethylene glycol butyl ether to dipropylene glycol butyl ether is 3.3:1. Described water-based polyurethane resin emulsion is the mixed solution that model is the water-based polyurethane resin emulsion of KT200 and the water-based polyurethane resin emulsion of KT803, and the model is that the water-based polyurethane resin emulsi...

Embodiment 2

[0038]A preparation method of an environmentally friendly paint, which comprises the following raw materials in parts by weight: 32 parts of water-based resin, 5 parts of dye auxiliaries, 65 parts of water, 3 parts of LT rheological additives, 0.7 parts of WT-204 rheological additives, 3-5 parts of film-forming aids, the water-based resin includes a water-based polyurethane resin emulsion and a water-based alkyd resin, and the weight ratio of the water-based polyurethane resin emulsion to the water-based alkyd resin is 1:1. The film-forming aid is a mixture of diethylene glycol butyl ether and dipropylene glycol butyl ether, and the weight ratio of diethylene glycol butyl ether to dipropylene glycol butyl ether is 3.8:1. Described water-based polyurethane resin emulsion is the mixed solution that model is the water-based polyurethane resin emulsion of KT200 and the water-based polyurethane resin emulsion of KT803, and the model is that the water-based polyurethane resin emulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com