Silane end capping agent-modified two-component polyurethane waterproof coating and preparation method thereof

A two-component polyurethane and waterproof coating technology, applied in the field of coatings, can solve the problems of products losing waterproof effect, air pollution, and bubbles, and achieve the effect of environmental protection and bubbles affecting product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

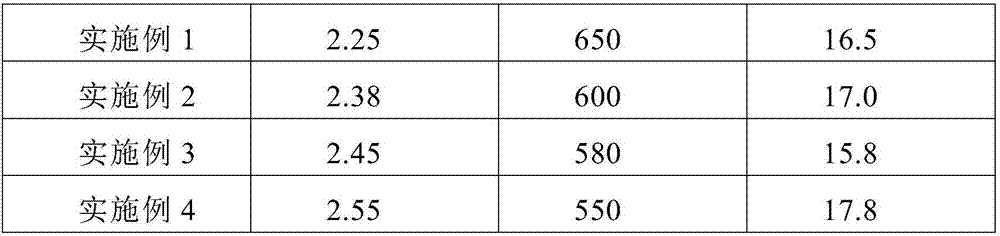

Embodiment 1

[0043] A silane-blocking agent modified two-component polyurethane coating is divided into A component and B component:

[0044] Raw material formula of component A: 40% polyether polyol 2000, 35% polyether polyol 3000, 2% toluene diisocyanate, 17% 3-isocyanatopropyl triethoxysilane, 4% chlorinated paraffin-42.

[0045] B component raw material formula: 5% aromatic oil, 5% polyether polyol 2000, 3% polyether polyol 3000, 15% chlorinated paraffin-42, 45% heavy calcium, 15% talc, 1% iron brown, 3.6% plasticizer, 0.2% catalyst, 0.2% defoamer, 7% environmentally friendly solvent methyl ether acetate malonate.

[0046] Put the raw materials of component A and component B in the mixer in turn, then mix components A and B uniformly according to the mass ratio of 1:2, and solidify to form a film.

Embodiment 2

[0048] A silane-blocking agent modified two-component polyurethane coating is divided into A component and B component:

[0049] Raw material formula of component A: 35% polyether polyol 2000, 39% polyether polyol 3000, 2.5% toluene diisocyanate, 19% 3-isocyanatopropyl triethoxysilane, 4.5% chlorinated paraffin-42.

[0050] B component raw material formula: 7% aromatic oil, 3% polyether polyol 2000, 5% polyether polyol 3000, 18% chlorinated paraffin-42, 40% heavy calcium, 15% talc, 1% iron brown, 3.6% plasticizer, 0.2% catalyst, 0.2% defoamer, 7% environmentally friendly solvent methyl ether acetate malonate.

[0051]Put the raw materials of component A and component B in the mixer in turn, then mix components A and B uniformly according to the mass ratio of 1:2.5, and solidify to form a film.

Embodiment 3

[0053] A silane-blocking agent modified two-component polyurethane coating is divided into A component and B component:

[0054] Raw material formula of component A: 30% polyether polyol 2000, 45% polyether polyol 3000, 3% toluene diisocyanate, 20% 3-isocyanatopropyl triethoxysilane, 2% chlorinated paraffin-42.

[0055] B component raw material formula: 5% aromatic oil, 4% polyether polyol 2000, 4% polyether polyol 3000, 15% chlorinated paraffin-42, 40% heavy calcium, 20% talcum powder, 1% iron brown, 3.6% plasticizer, 0.2% catalyst, 0.2% defoamer, 7% environmentally friendly solvent methyl ether acetate malonate.

[0056] Put the raw materials of component A and component B in the mixer in turn, then mix components A and B uniformly according to the mass ratio of 1:2.5, and solidify to form a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com