High viscosity environmental-friendly double-sided adhesive tape capable of being repeatedly used and manufacturing method thereof

A double-sided tape, high-viscosity technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc. Problems such as weak knot force and poor dimensional stability can achieve good curing effect, good initiation effect, and the effect of inhibiting the oxidation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

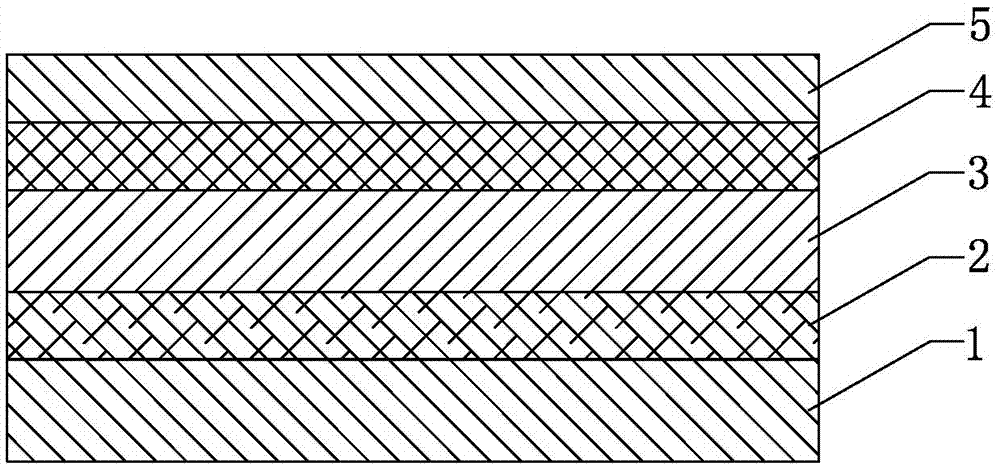

[0048] See figure 1 , environmentally friendly double-sided tape, the high-viscosity double-sided tape includes a first release film 1, a low-viscosity layer 2, a substrate layer 3, a high-viscosity layer 4 and a second release film arranged in sequence from bottom to top 5. The lower surface and the upper surface of the low-viscosity layer 2 are attached to the upper surface of the first release film 1 and the lower surface of the substrate layer 3 respectively, and the lower surface and the upper surface of the high-viscosity layer 4 are respectively bonded to the substrate. The upper surface of the layer 3 and the lower surface of the second release film 5 are pasted together.

[0049] The first release film 1 is a transparent fluorine release film; the low-viscosity layer 2 is a silica gel layer with a peeling force of 600-800g / 25mm; the substrate layer 3 is a film with a light transmittance ≥ 95%. PET film; the high adhesive layer 4 is an optical adhesive layer with a pe...

Embodiment 2

[0056] The difference between this embodiment and the above-mentioned embodiment 1 is that the optical adhesive layer includes the following raw materials in parts by weight:

[0057]Acrylic monomer 80 parts

[0058] Thickener 4 parts

[0059] Hardener 2 parts

[0060] Initiator 1 part

[0061] 1 part coupling agent

[0062] 1 part defoamer

[0063] Anti-ultraviolet agent 0.5 parts

[0064] Antioxidant 0.8 parts.

[0065] The acrylic monomer is a mixture composed of butyl acrylate, cyanoacrylate, hydroxypropyl methacrylate and tricarboxymethylpropane triacrylate in a weight ratio of 2:1.5:0.5:1.

[0066] The thickener is a mixture of carboxymethylcellulose, hydroxyethylcellulose and hydroxypropylmethylcellulose in a weight ratio of 1:1.5:0.5.

[0067] The curing agent is a mixture composed of isocyanate, methylene dicyclohexylamine and glycidyl methacrylate in a weight ratio of 1:0.8:1.4.

[0068] The initiator is composed of 2-hydroxyl-2-phenylacetophenone, 2-methyl-2...

Embodiment 3

[0074] The difference between this embodiment and the above-mentioned embodiment 1 is that the optical adhesive layer includes the following raw materials in parts by weight:

[0075] Acrylic monomer 90 parts

[0076] Thickener 5 parts

[0077] 3 parts curing agent

[0078] Initiator 2 parts

[0079] 1.5 parts of coupling agent

[0080] 1.2 parts of defoamer

[0081] Anti-ultraviolet agent 0.8 parts

[0082] Antioxidant 0.9 parts.

[0083] The acrylic monomer is a mixture composed of butyl acrylate, cyanoacrylate, hydroxypropyl methacrylate and tricarboxymethylpropane triacrylate in a weight ratio of 2.5:1.8:0.8:1.

[0084] The thickener is a mixture of carboxymethylcellulose, hydroxyethylcellulose and hydroxypropylmethylcellulose in a weight ratio of 1:1.8:0.8.

[0085] The curing agent is a mixture composed of isocyanate, methylene bicyclohexaneamine and glycidyl methacrylate in a weight ratio of 1:0.9:1.6.

[0086] The initiator is composed of 2-hydroxyl-2-phenylace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com