Prefabricated sandwiched thermal-insulation wallboard with novel connectors

A technology of prefabricated wall panels and thermal insulation wall panels, applied in building components, buildings, building structures, etc., can solve the problems of thermal bridges that cannot be properly solved, increased processing and installation costs of wall panels, and unfavorable cost control. Avoid thermal bridge effect, good thermal insulation and fire protection effect, quick installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

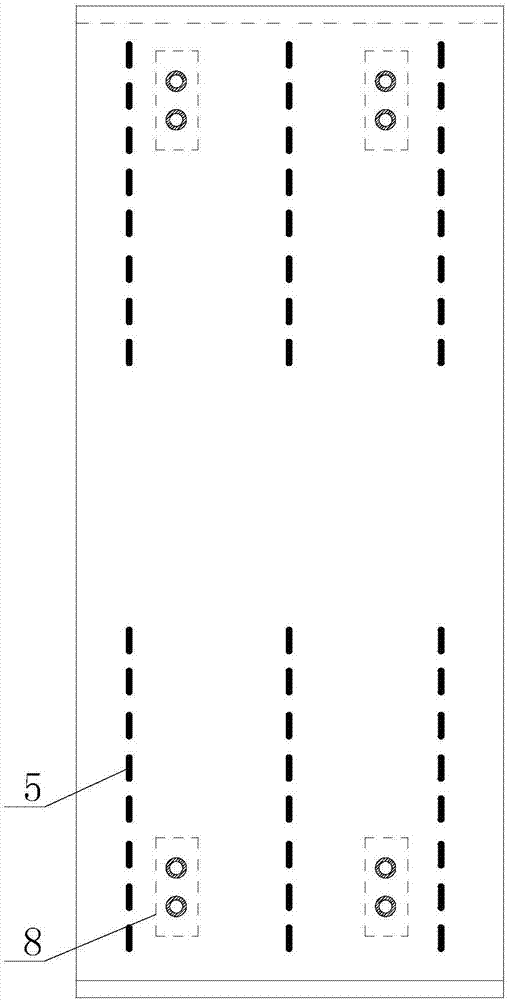

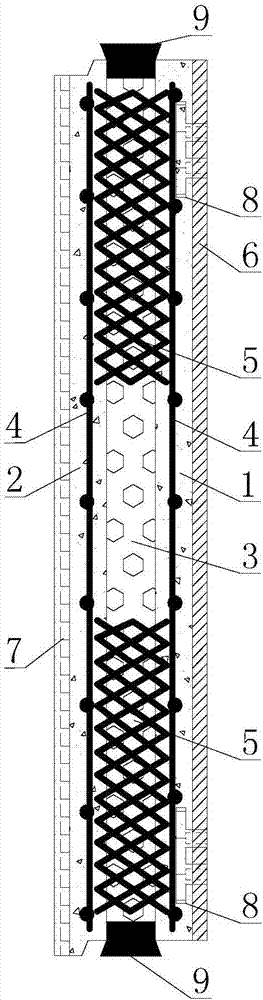

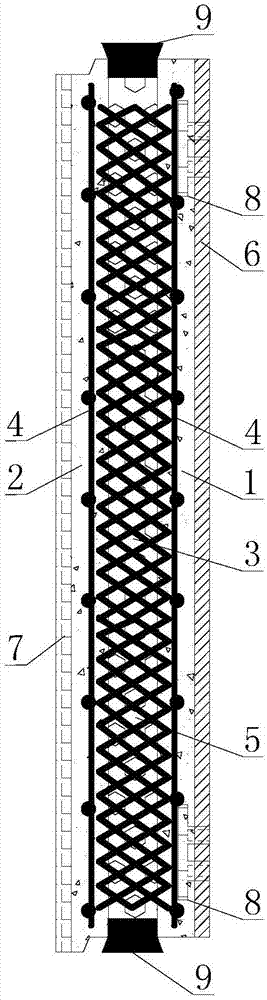

[0026] Such as Figure 1-5 Shown: a prefabricated sandwich insulation wall panel with a new type of connector, including prefabricated wall panel inner leaf wall 1, prefabricated wall panel outer leaf wall 2, sandwich insulation layer 3, stressed steel bar 4, mesh fiber Connector 5, inner decoration layer 6, outer decoration layer 7, installation connector 8 and rubber airtight strip 9;

[0027] The prefabricated sandwich insulation wall panel is divided into prefabricated wall panel inner leaf wall 1, sandwich insulation layer 3 and prefabricated wall panel outer leaf wall 2 from inside to outside, prefabricated wall panel inner leaf wall 1 and prefabricated wall panel outer leaf wall 2 is provided with stress steel bars 4, and the upper and lower ends of the sandwich insulation layer 3 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com