A compact photonic structure based on microring cavity to realize multiple resonance line shapes

A technology of photonic structure and microring, applied in the coupling of optical waveguide, etc., can solve the problem of insufficient compactness, and achieve the effect of small processing error, compact photonic structure, and low processing technology requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

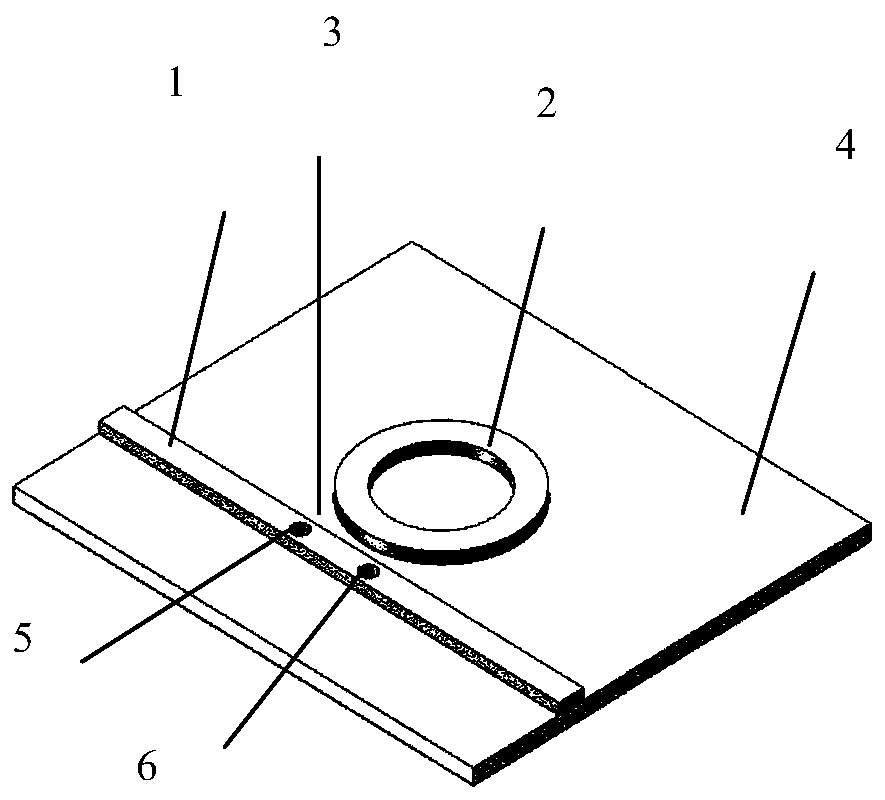

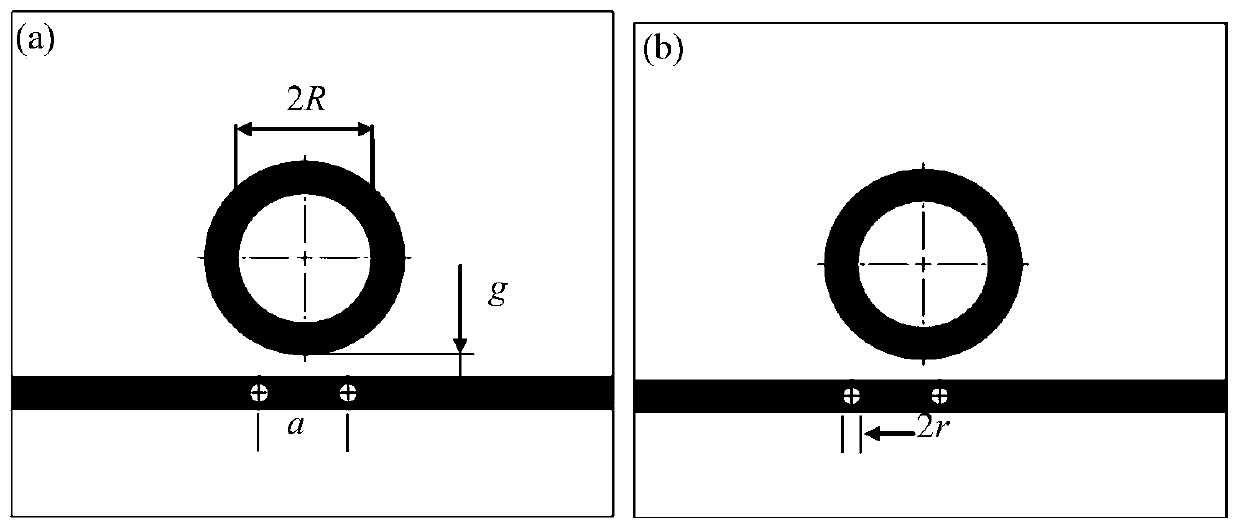

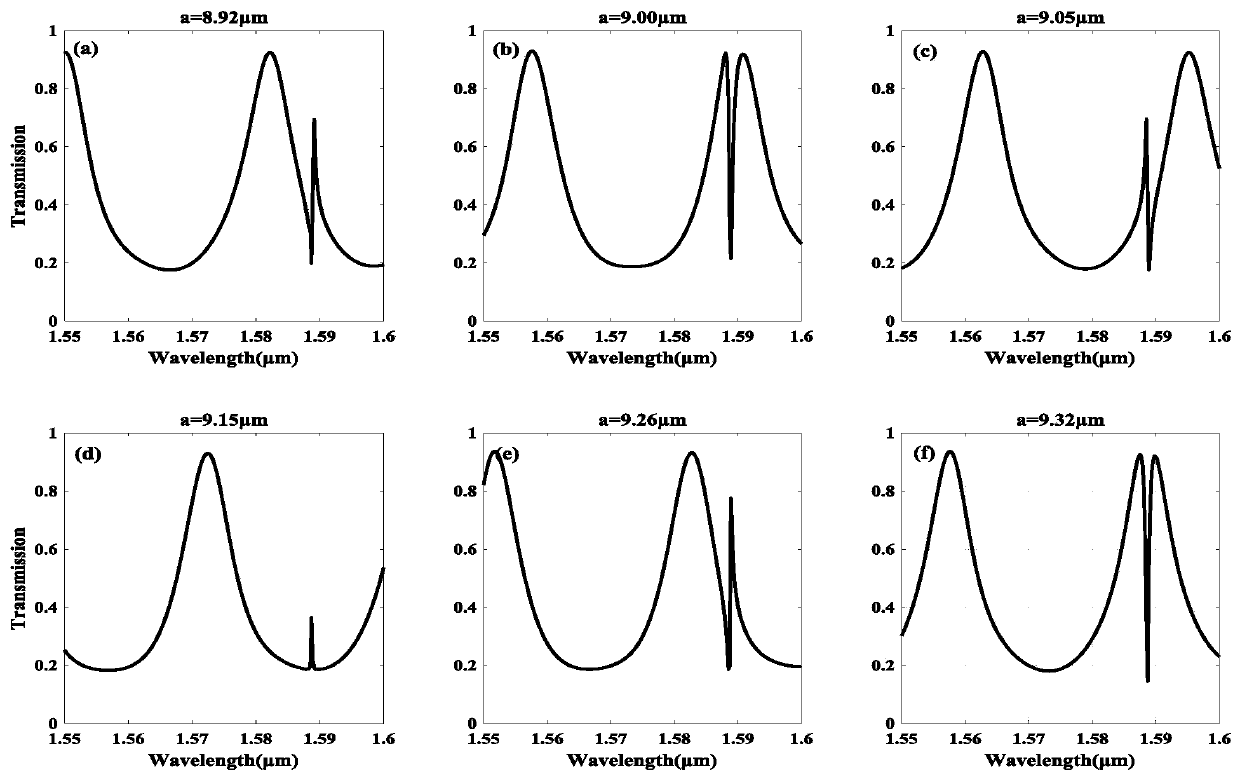

[0030] The embodiment of the present invention proposes a compact photonic structure based on a microring cavity to realize multiple resonance line types, such as figure 1 As shown in Fig. 1, the structure is based on the traditional micro-ring cavity side-coupled straight waveguide structure, and two air holes are dug out in the straight waveguide. Two air holes can be distributed symmetrically about the microring cavity figure 2 (a), also available off-centre figure 2 (b).

[0031] The materials used for the straight waveguide 1 and the micro-ring cavity 2 are generally high refractive index or have a high refractive index relative to its substrate and cladding, and there are group IV materials such as silicon, silicon nitride, silicon oxynitride, etc., III-V semiconductor materials such as gallium phosphide, lithium niobate, and certain polymers such as p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com