Silicon controlled rectifier module with sieve-aperture-shaped low-stress copper lead electrode, and assembling method for silicon controlled rectifier module

A lead electrode, low stress technology, used in circuits, electrical components, electrical solid devices, etc., can solve the problems of limiting product load power, poor heat dissipation capacity of molybdenum material, and overcurrent capacity limitations, to improve rapid heat dissipation capacity, improve Efficiency, effect of reducing transverse stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

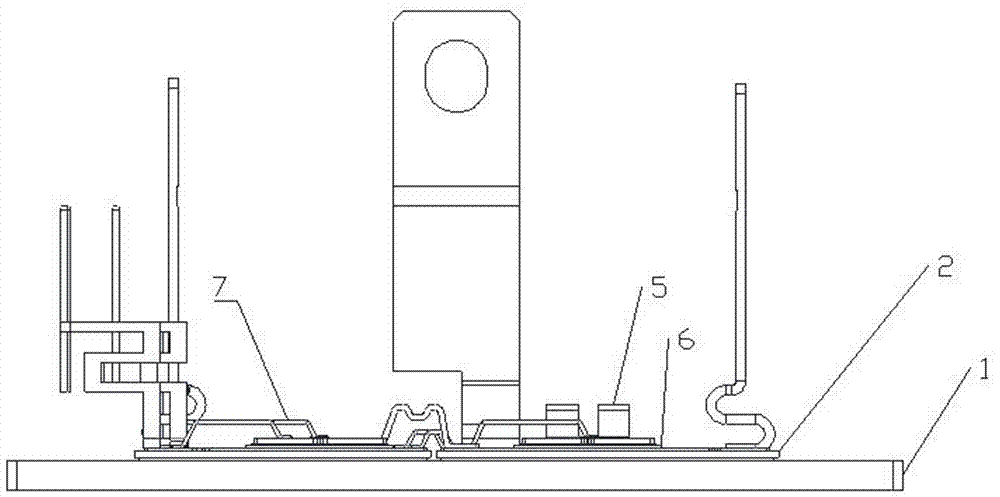

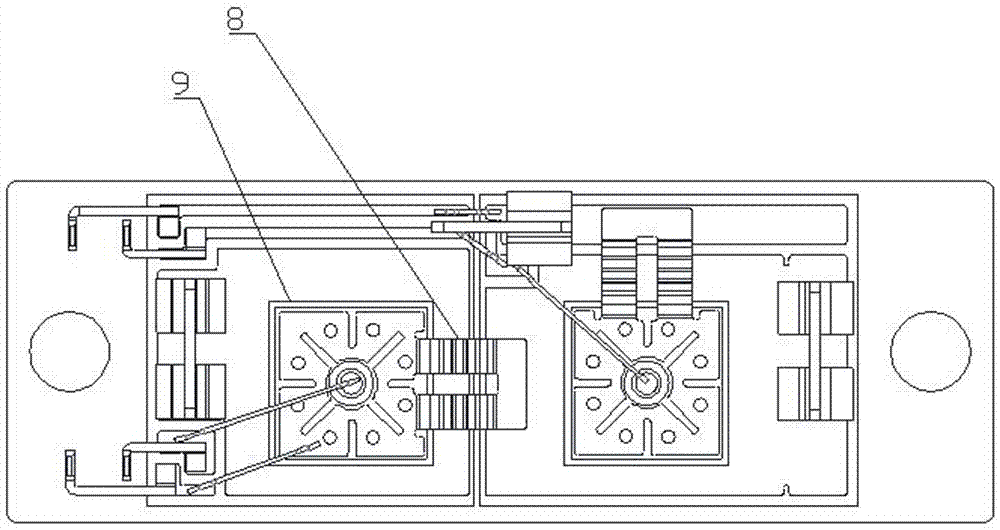

[0035] Such as Figure 1-12 As shown, the thyristor module with sieve-shaped low-stress copper lead electrodes includes a metal base plate 1, a ceramic copper-clad laminate base 2, the ceramic copper-clad laminate base 2 is welded on the metal base plate 1, and the ceramic copper-clad laminate base 2 is welded with a A chip 6, a second chip 9, an aluminum wire 7, a copper inner lead electrode sheet, the cathode surfaces of the first chip 6 and the second chip 9 are respectively provided with a first copper inner lead electrode sheet 5 and a second copper inner lead electrode sheet 8, the lead-out ends of the first copper inner lead electrode sheet 5 and the second copper inner lead electrode sheet 8 are welded on the base 2 of the ceramic copper clad laminate.

[0036] There are one or more hollowed-out elongated and circular mesh holes 4 on the contact surfaces of the first and second copper inner lead electrode sheets and the first and second chips.

[0037] There are one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com