Water supply device for automatic feed feeder using potential difference between two potential sensing needles

A technology of supplying device and potential difference, which is applied in the direction of animal drinking device, animal feeding device, non-electric variable control, etc., can solve the problem of water not flowing out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

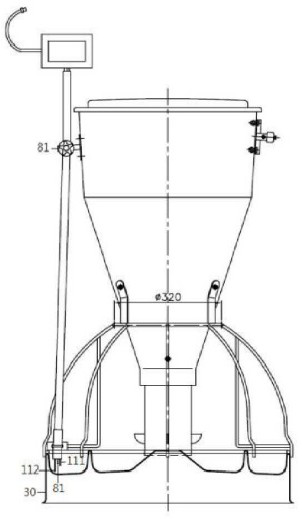

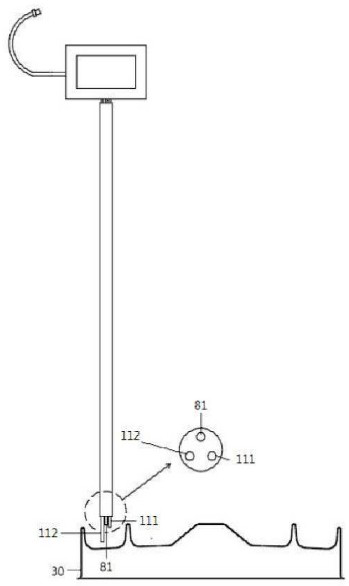

[0016] In the present invention, the water supply device of the automatic feed feeder which utilizes the potential difference of two potential sensing needles includes: a feed substrate 30 containing feed or water so that the pigs can eat it; a feed supply part, which supplies feed to the feeding substrate 30; a water supply part, which supplies water to the feeding substrate 30;

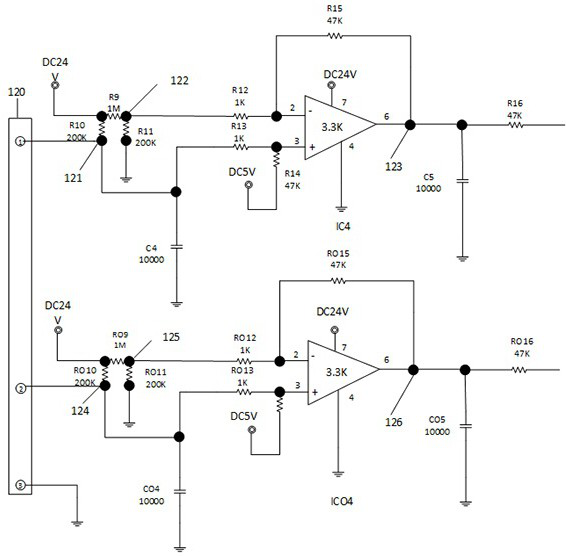

[0017] It is characterized in that, the water supply part includes: a water supply pipe, which is provided to obtain the supply of water to be supplied to the supply substrate 30; and a solenoid valve 81, which is provided in a part of the water supply pipe, according to the control part. The voltage signal is switched on and off, so as to be able to control whether the moving water moves or not; the upper potential sensing needle 111 is arranged on the feeding substrate 30 in a form of a certain height isolation, and senses the water level of the upper water , so that the water does not overflow; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com