Pipette tip automatic cleaning device

An automatic cleaning and pipetting technology, which is applied in the field of experimental equipment, can solve the problems of increasing the cost of equipment consumables, waste of resources, and heavy workload, and achieve the effects of saving equipment consumable costs, prolonging the service life, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

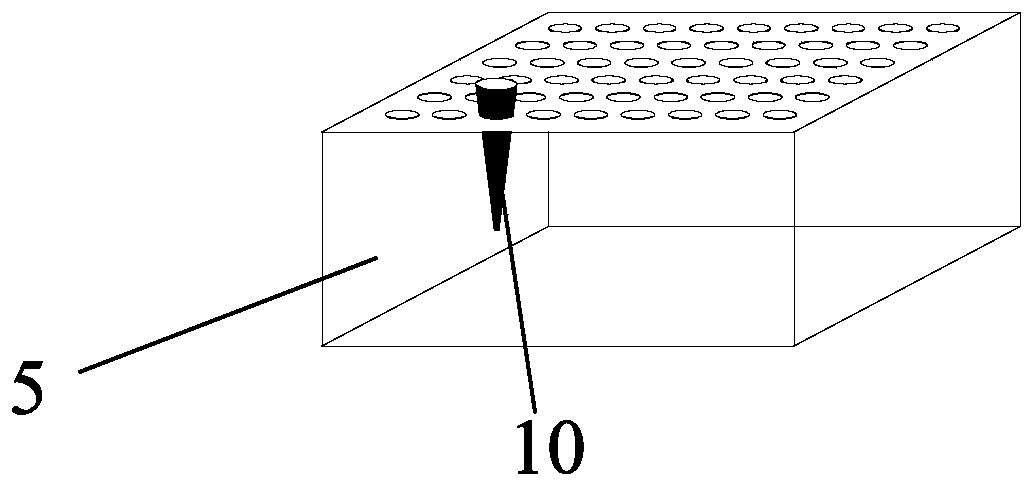

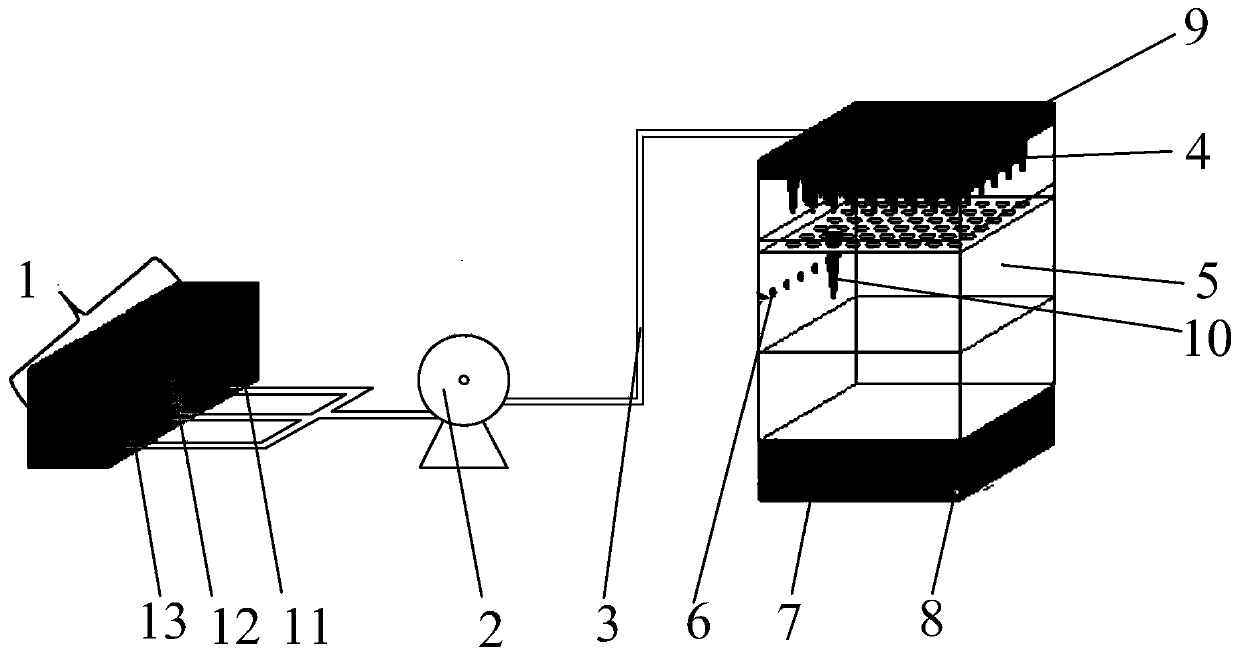

[0020] see figure 1 and figure 2 , figure 1 It is a structural schematic diagram of a pipette tip support of a preferred embodiment of the automatic pipette tip cleaning device of the present invention, figure 2 It is a structural schematic diagram of the preferred embodiment. The pipette tip automatic cleaning device of the present invention mainly includes: a lotion tank 1 for containing lotion, a pump 2, a hollow tube 3, a spray head 4, and a pipette tip bracket for inserting a pipette tip 10 5. The spray hole 6, the waste liquid tank 7, the sewage outlet 8, the cleaning box 9 and the automatic control system (not shown) for controlling the automatic cleaning device of the pipette tip to execute the preset cleaning program; the spray head 4 Set on the top of the cleaning box 9, the pipette tip bracket 5 is set directly below the spray head 4 in the cleaning box 9 so that the pipette tip 10 corresponds to the spray head 4 one by one, and the spray hole 6 is set in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com