Biological compound soil conditioner and preparation method thereof

A soil improver and biological technology, applied in the direction of urea compound fertilizer, fertilizer mixture, application, etc., can solve problems such as gaps, land resources in mining areas, and ecological environment damage, and achieve low cost, rich surface chemical functional groups, and high nutrient content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

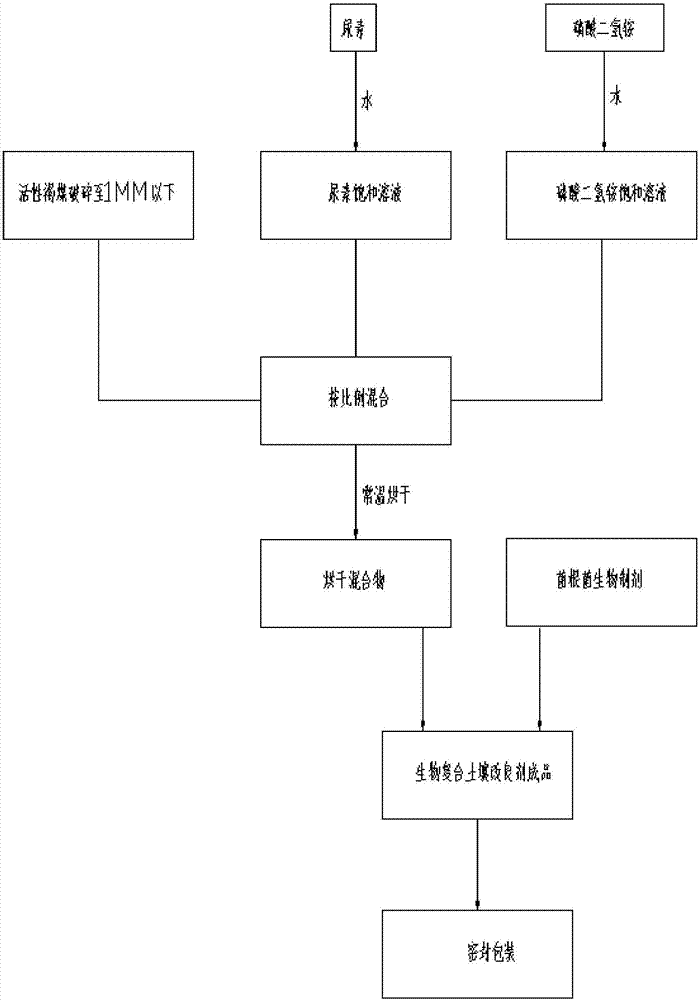

[0020] The raw material is selected from the active lignite produced from Yimin lignite as the substrate, and the preparation method of the biocomposite soil conditioner is as follows: figure 1 shown, including the following steps:

[0021] Step 1: active lignite crushing and screening: crushing and sieving active lignite to wide sieving particles with a diameter of less than 1mm;

[0022] Step 2: Preparation of urea solution: Dissolve 5 kg of urea granules in water at room temperature to make a saturated urea solution;

[0023] Step 3: Preparation of ammonium dihydrogen phosphate solution: Dissolve 5 kg of ammonium dihydrogen phosphate particles in normal temperature water to make a saturated solution of ammonium dihydrogen phosphate;

[0024] Step 4: by mass percentage, the active lignite of 89kg is mixed with the urea solution that urea content is 5kg and the ammonium dihydrogen phosphate solution that ammonium dihydrogen phosphate content is 5kg;

[0025] Step 5: drying ...

Embodiment 2

[0029] The raw material is selected from the active lignite produced from Yimin lignite as the substrate, and the preparation method of the biocomposite soil conditioner is as follows: figure 1 shown, including the following steps:

[0030] Step 1: active lignite crushing and screening: crushing and sieving active lignite to wide sieving particles with a diameter of less than 1mm;

[0031] Step 2: Preparation of urea solution: Dissolve 10kg of urea granules in water at room temperature to make a saturated urea solution;

[0032] Step 3: Preparation of ammonium dihydrogen phosphate solution: Dissolve 10 kg of ammonium dihydrogen phosphate particles in normal temperature water to make a saturated solution of ammonium dihydrogen phosphate;

[0033] Step 4: by mass percentage, the active lignite of 77kg is mixed with the urea solution that urea content is 10kg and the ammonium dihydrogen phosphate solution that ammonium dihydrogen phosphate content is 10kg;

[0034] Step 5: dryi...

Embodiment 3

[0038] The raw material is selected from the active lignite produced from Yimin lignite as the substrate, and the preparation method of the biocomposite soil conditioner is as follows: figure 1 shown, including the following steps:

[0039] Step 1: active lignite crushing and screening: crushing and sieving active lignite to wide sieving particles with a diameter of less than 1 mm;

[0040] Step 2: Preparation of urea solution: Dissolve 20kg of urea granules in water at room temperature to make a saturated urea solution;

[0041] Step 3: Preparation of ammonium dihydrogen phosphate solution: Dissolve 20kg of ammonium dihydrogen phosphate particles in normal temperature water to make a saturated ammonium dihydrogen phosphate solution;

[0042] Step 4: by mass percentage, the active lignite of 56kg is mixed with the urea solution that urea content is 20kg and the ammonium dihydrogen phosphate solution that ammonium dihydrogen phosphate content is 20kg;

[0043] Step 5: drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com