Organic vacuum evaporation source

A vacuum evaporation and organic technology, applied in the field of organic vacuum evaporation source equipment, can solve the problems of lack of vacuum equipment, achieve low cost, avoid local overheating, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

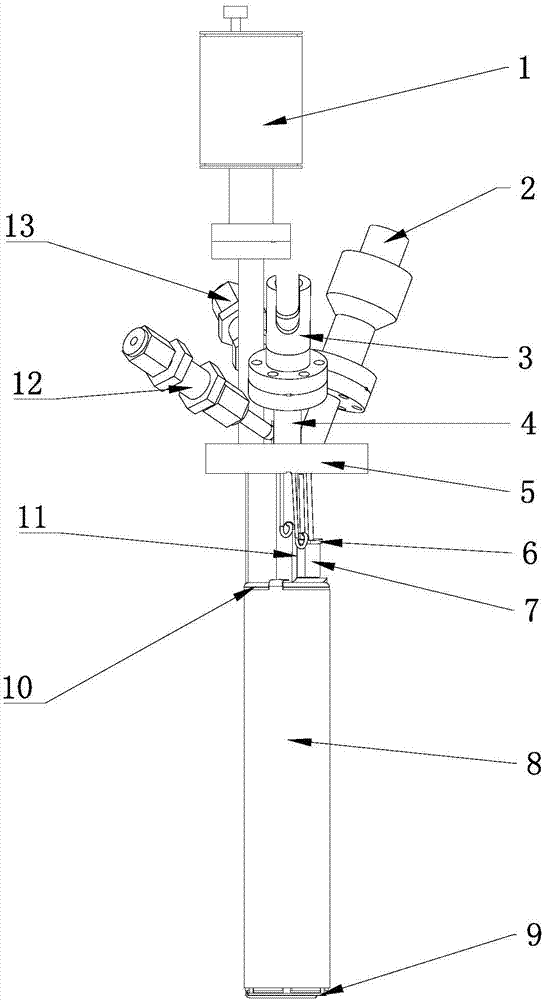

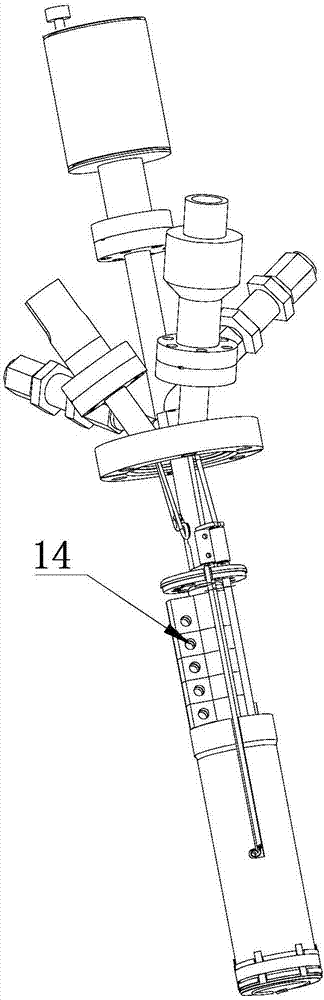

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 An organic vacuum evaporation source shown includes: a heating system, a cooling system, a temperature measuring system, a control system and connecting components;

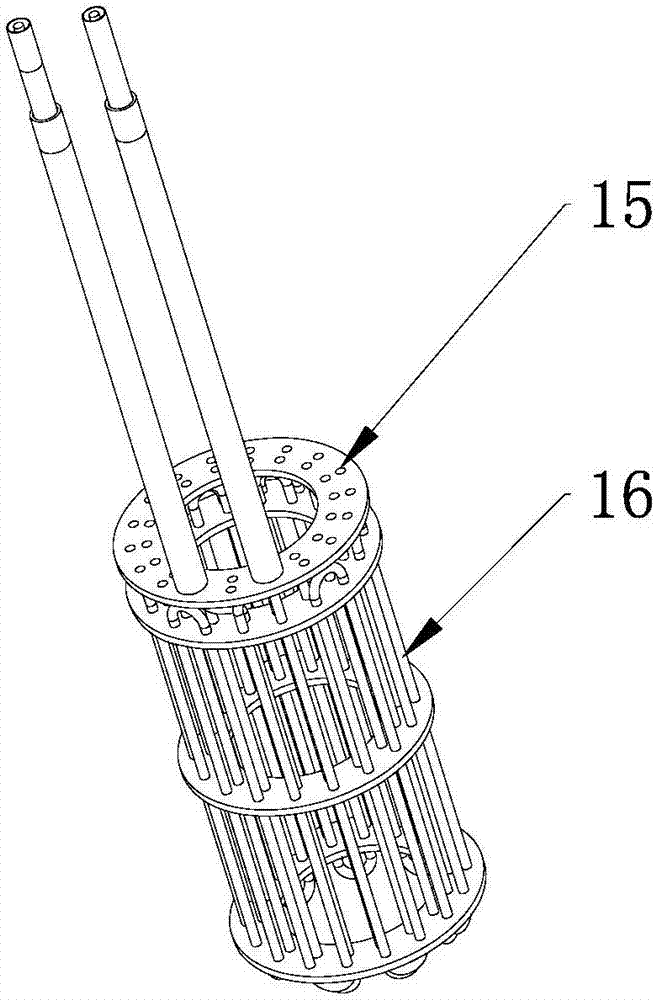

[0038] The heating system includes: electrode port 2, heating wire 16, metal heat conductor 21, crucible 17, fixing ring 15 and connector 7;

[0039] Among them, the heating wire 16 and the four fixing rings 15 form a hollow cylindrical heating core; one end of the electrode port 2 is connected with the power supply joint of the connecting piece 7 and the heating wire 16, and the other end is connected to the power supply for heating; the metal heat conductor 21 is Columnar body, the top end of the metal heat conductor 21 is provided with an axially downward crucible groove 21.1 for embedding the crucible 17, and the bottom end is provided with an axially upwardly extending heating core embedding groove 21.2 for embedding the heating cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com