In-situ Raman spectrum measurement method and measurement device for high temperature volatile and corrosive fused salt

A Raman spectroscopy, in-situ measurement technology, applied in measurement devices, Raman scattering, material excitation analysis, etc., can solve the problems of high cost, difficult operation, unsatisfactory effect, etc. Adjustment, temperature measurement point controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

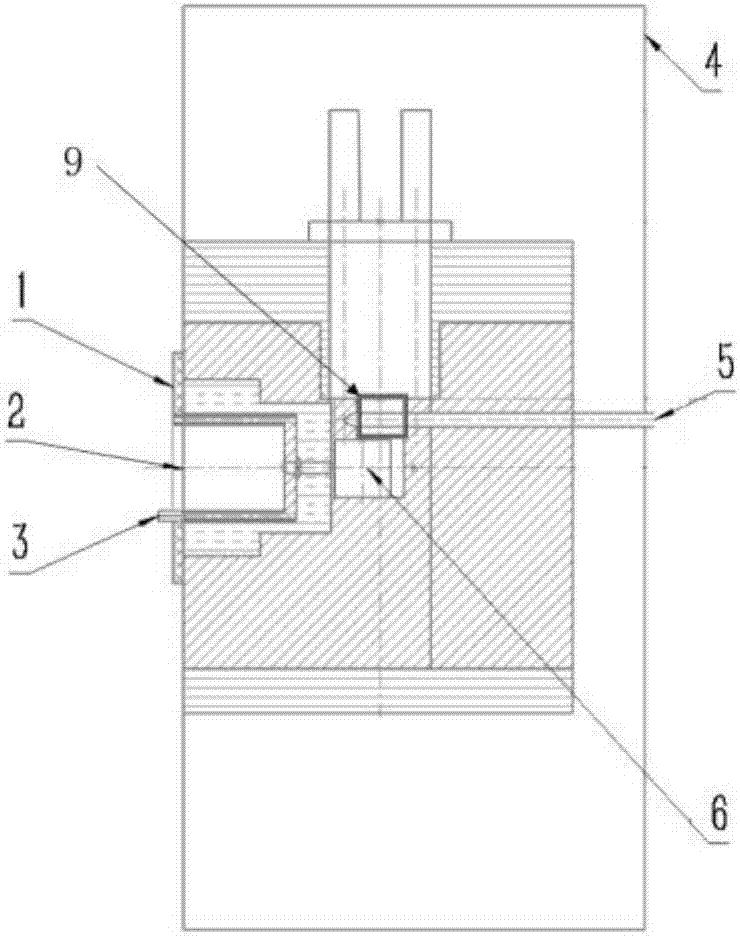

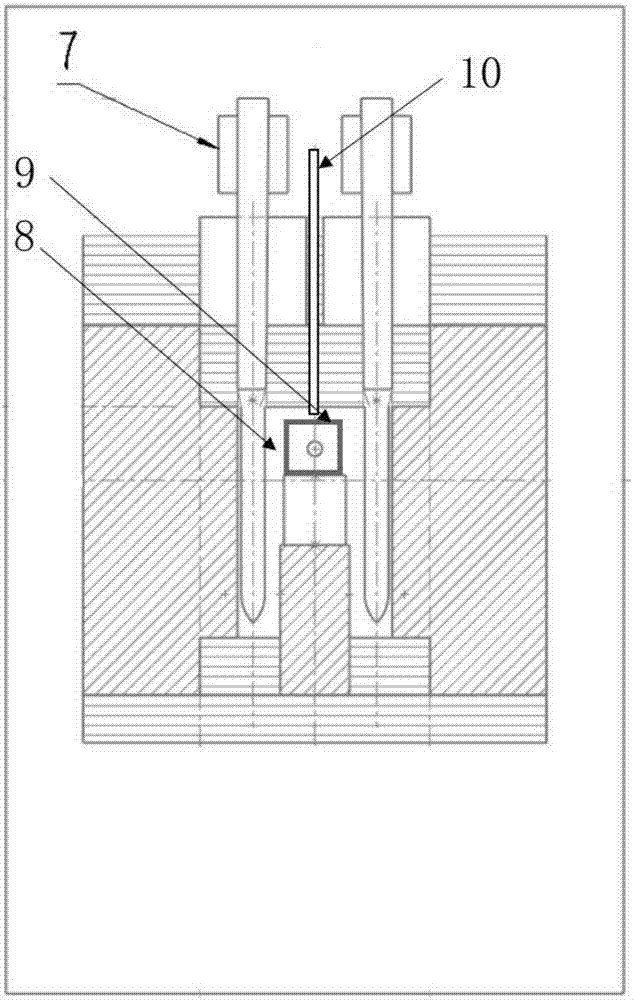

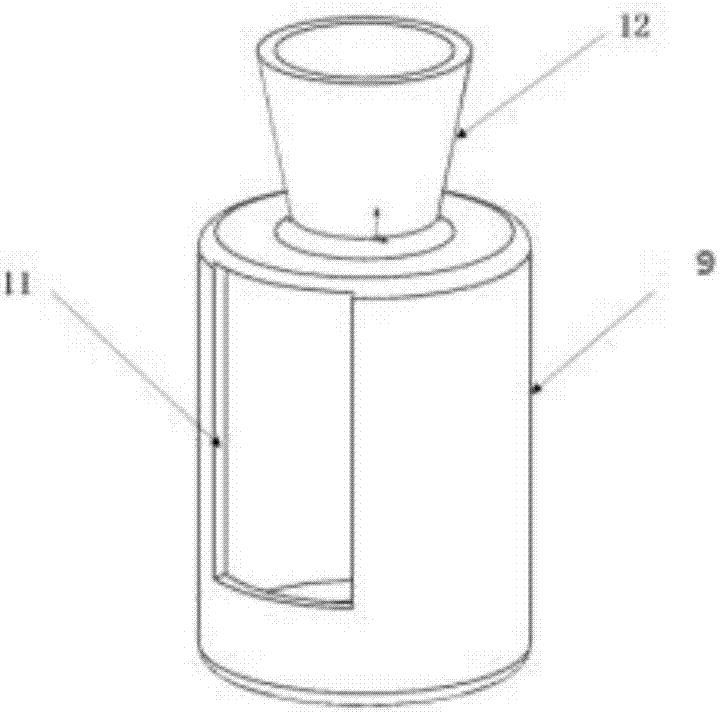

[0034] A kind of Raman spectroscopic in-situ measurement method that is used for high-temperature volatilization corrosive molten salt, uses a kind of Raman spectroscopic in-situ measurement device, comprises Raman spectrometer, corner objective lens, external heating furnace (such as Figure 1-2 As shown), the special quartz crucible 9, the laser is emitted by the Raman spectrometer, the corner objective lens is connected to the Raman spectrometer to export the laser light, the corner objective lens probe extends into the central hole of the cooling water furnace door, and the laser light shines on the quartz crucible loaded with samples , and collect the signal through the original optical path.

[0035] The above-mentioned external heating furnace also includes: a furnace body 4, a heating element 7, a thermocouple 5, a water-cooled furnace door 1, a program temperature control instrument (control cabinet), and the heating element and the thermocouple are respectively connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com