Water pressure monitoring device

A monitoring device and water pressure technology, which is applied in fire rescue and other fields, can solve the problems of insufficient water pressure of fire hydrants, difficulty in connecting power supply, and theft of fire hydrants, etc. It has strong performance of saturation and charging acceptance, improves safety and stability, and is effective management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

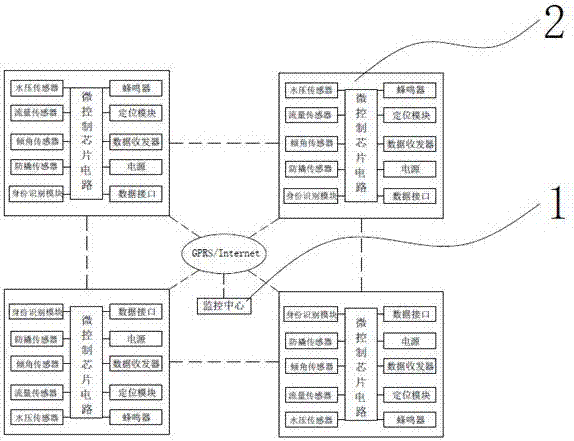

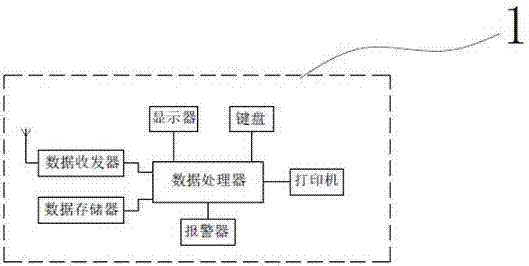

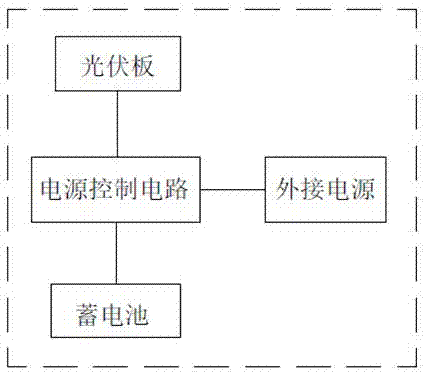

[0021] Such as Figure 1~5 As shown, a water pressure monitoring device includes a fire hydrant 16, a detector 2 installed on the fire hydrant 16, and a monitoring center 1 connected to the detector 2. The detector 2 is connected to the monitoring center 1 through a wireless network, and the monitoring center 1 Including a data processor and a display, the data processor is connected with a display, a keyboard, a printer, an alarm, a data memory and a data transceiver, the detector 2 includes a micro-control chip circuit, and the micro-control chip circuit is connected with a water pressure sensor, a flow sensor, Inclination sensor, anti-tamper sensor, identification module, buzzer, positioning module, data transceiver, power supply and data interface, the power supply includes a power control circuit, the power control circuit is connected with a photovoltaic panel, a battery and an external power supply, and the battery is lead-acid Battery, battery electrolyte is composed o...

Embodiment 2

[0028] Such as Figure 1~5As shown, a water pressure monitoring device includes a fire hydrant 16, a detector 2 installed on the fire hydrant 16, and a monitoring center 1 connected to the detector 2. The detector 2 is connected to the monitoring center 1 through a wireless network, and the monitoring center 1 Including a data processor and a display, the data processor is connected with a display, a keyboard, a printer, an alarm, a data memory and a data transceiver, the detector 2 includes a micro-control chip circuit, and the micro-control chip circuit is connected with a water pressure sensor, a flow sensor, Inclination sensor, anti-tamper sensor, identification module, buzzer, positioning module, data transceiver, power supply and data interface, the power supply includes a power control circuit, the power control circuit is connected with a photovoltaic panel, a battery and an external power supply, and the battery is lead-acid Storage battery, the electrolyte solution o...

Embodiment 3

[0041] The actual use of the water pressure monitoring device of the present invention:

[0042] Such as Figure 1~5 As shown, when the management and maintenance personnel are going to inspect the fire hydrant 16, they need to carry the induction card containing personal information with them, and the identification module arranged on the fire hydrant 16 will automatically instruct the detector 2 to disarm, and simultaneously upload the relevant information to the Monitoring center 1, monitoring center 1 displays the information of the inspection personnel, inspection time, fire hydrant 16 number, and the area where the inspection is completed. After the personnel leave, the identification module cannot search for the proximity card signal within 3 minutes. At this time, the detector 2 It will automatically re-arm, and at the same time upload the arming information to the monitoring center 1. According to the needs, a short-distance card swiping sign-in device can be added to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com