Anti-corrosion FRP full grouting sleeve and manufacturing method thereof

A full grouting and anti-corrosion technology, which is applied in auxiliary forming equipment, bridge parts, bridges, etc., can solve the problems of low shear stiffness and achieve the effect of improving poor corrosion resistance and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the anti-corrosion FRP full grouting sleeve for longitudinal reinforcement connection of the present invention will be described below in conjunction with the accompanying drawings:

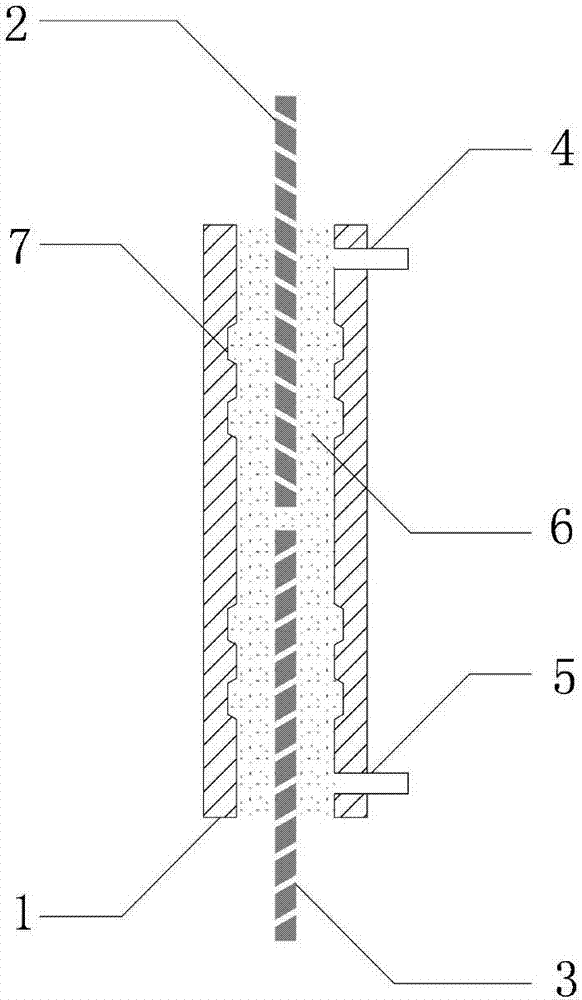

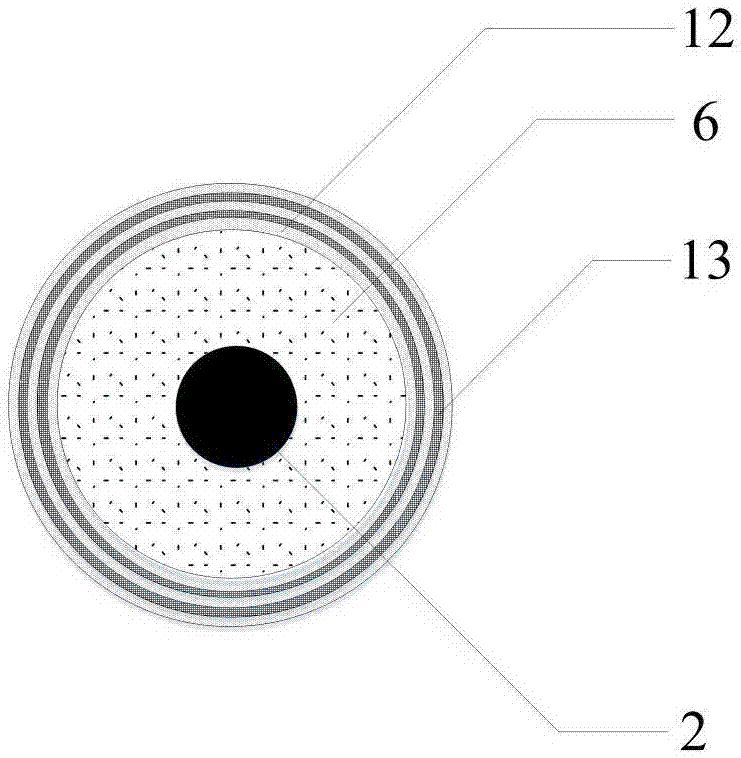

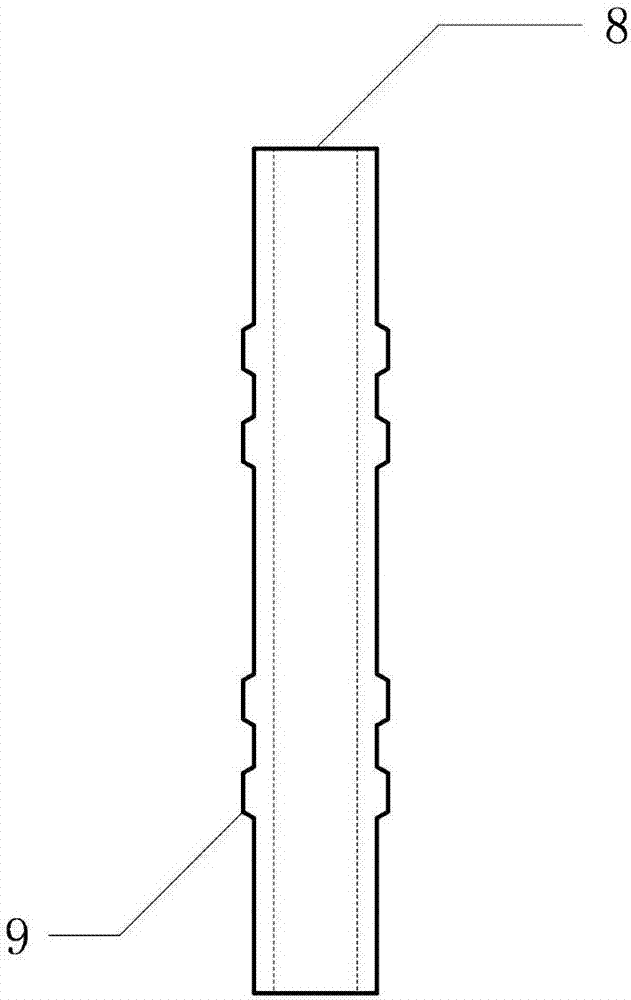

[0024] Such as figure 1 , 2 , 3, and 4 show a corrosion-resistant FRP full-grouting sleeve. The FRP sleeve body 1 is the main structure of the full-grouting sleeve. Inside the FRP sleeve body 1; on the side of the steel bar insertion section of the FRP sleeve body 1, there are respectively grouting ports 4 and grout outlets 5, and the inner cavity of the FRP sleeve body 1 is high-strength grouting material 6; the FRP sleeve body 1 Grooves 7 are provided on the inner wall of the inner wall, and the grooves 7 are used to increase the mechanical engagement force between the high-strength grouting material 6 and the FRP sleeve body 1, and improve connection reliability. The FRP sleeve body 1 is formed by wrapping FRP cloth in layers on a steel pipe mold 8. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com