Supercapacitor based on graphene/silicon-aluminum gel material and preparation of supercapacitor

A technology of supercapacitors and gelling materials, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor separators, hybrid capacitor electrodes, etc., can solve problems such as the influence of mechanical properties, and achieve energy storage structure integration and good capacitance performance , The effect of low carbon and no pollution in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

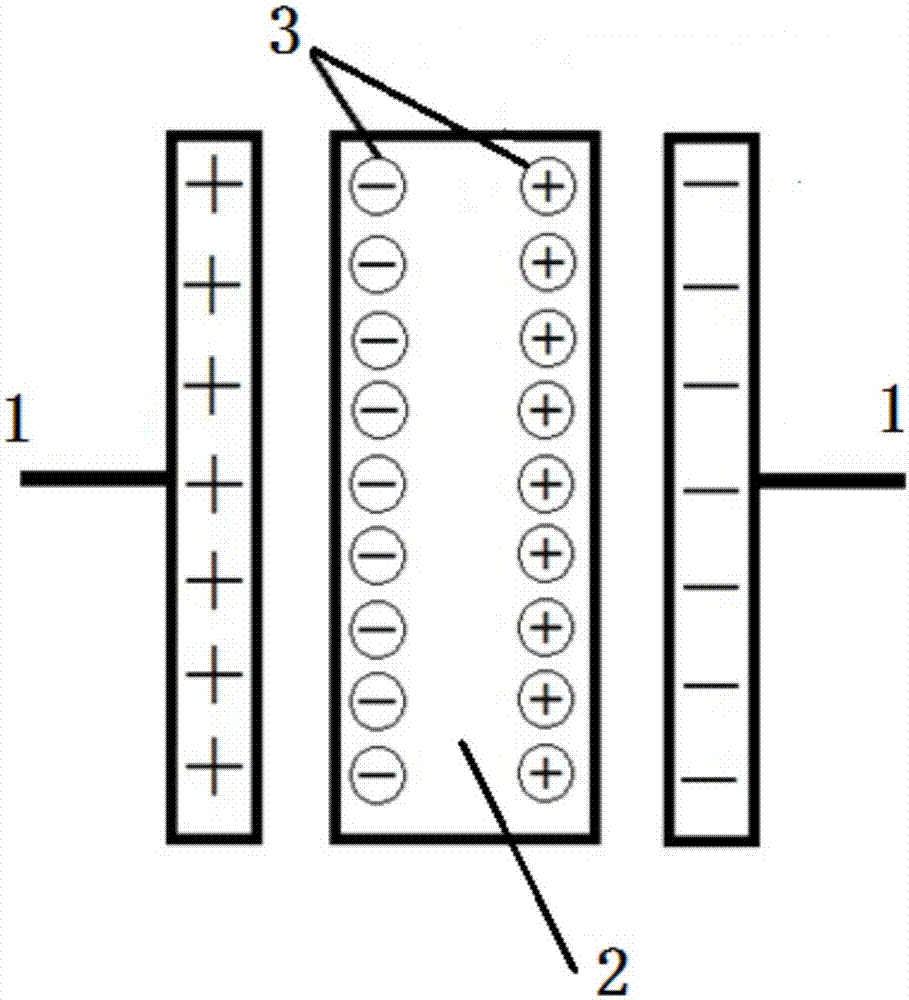

[0034] Weigh 100g of water glass, 6.82g of NaOH solid, and 30g of deionized water for mixing and stirring. After stirring evenly, let stand for 24 hours to obtain an alkali activator solution with a modulus of 2.0. Weigh 100g of metakaolin, introduce the alkali activator solution into the slurry mixer, and slowly add metakaolin while stirring at a constant speed, stir slowly for 120s, and stir quickly for 120s. The slurry was then added to a ring mold with a diameter of 10 mm and a thickness of 1 mm and a cube mold with a side length of 20 mm. After 24 hours, put them into the curing room (20°C±1°C, relative humidity about 90%) for curing.

[0035] After 28 days, the circular silica-alumina gel material sample in the curing room was taken out to obtain the interlayer material, which was immersed in a 2mol / L KOH solution to fully saturate it.

[0036] Electrode preparation: Weigh 80 mg of highly conductive graphene (), 15 mg of carbon black, and 5 mg of polytetrafluoroethylene...

Embodiment 2

[0041] Weigh 100g of water glass, 8.74g of NaOH solid, and 30g of deionized water for mixing and stirring. After stirring evenly, let stand for 24 hours to obtain an alkali activator solution with a modulus of 1.8. Weigh 100g of metakaolin, introduce the alkali activator solution into the slurry mixer, and slowly add metakaolin while stirring at a constant speed, stir slowly for 120s, and stir quickly for 120s. The slurry was then added to a ring mold with a diameter of 10 mm and a thickness of 1 mm and a cube mold with a side length of 20 mm. After 24 hours, put them into the curing room (20°C±1°C, relative humidity about 90%) for curing.

[0042] After 28 days, the circular silica-alumina gel material sample in the curing room was taken out to obtain the interlayer material, which was immersed in a 2mol / L KOH solution to fully saturate it.

[0043] Electrode preparation: Weigh 80 mg of highly conductive graphene, 15 mg of carbon black, and 5 mg of polytetrafluoroethylene PT...

Embodiment 3

[0048] Weigh 100g of water glass, 11.12g of NaOH solid, and 30g of deionized water for mixing and stirring. After stirring evenly, let stand for 24 hours to obtain an alkali activator solution with a modulus of 1.6. Weigh 100g of metakaolin, introduce the alkali activator solution into the slurry mixer, and slowly add metakaolin while stirring at a constant speed, stir slowly for 120s, and stir quickly for 120s. The slurry was then added to a ring mold with a diameter of 10 mm and a thickness of 1 mm and a cube mold with a side length of 20 mm. After 24 hours, put them into the curing room (20°C±1°C, relative humidity about 90%) for curing.

[0049] After 28 days, the circular silica-alumina gel material sample in the curing room was taken out to obtain the interlayer material, which was immersed in a 2mol / L KOH solution to fully saturate it.

[0050] Electrode preparation: Weigh 80 mg of highly conductive graphene, 15 mg of carbon black, and 5 mg of polytetrafluoroethylene P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com