Novel cylindrical lithium battery PACK automatic separation and automatic assembling machine

An automatic assembling machine and automatic sorting technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, climate sustainability, etc. The effect of improving reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

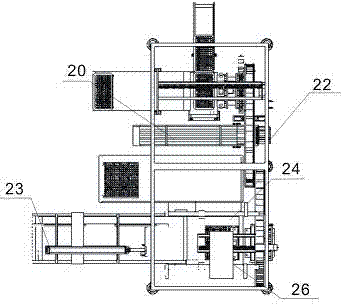

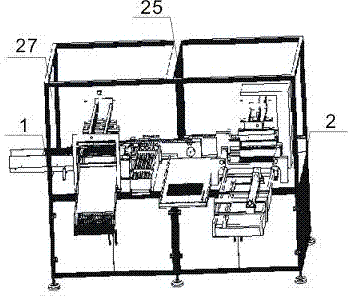

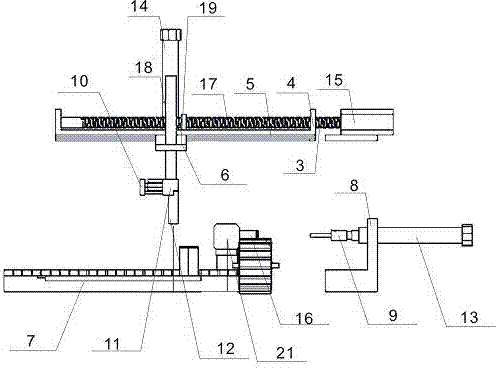

[0022] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0023] Such as figure 1 with 9 The preferred embodiment of a novel cylindrical lithium battery PACK automatic sorting and automatic assembly machine shown in the present invention includes a fuselage 1, an assembly line 2, a probe 3, a screw rod 4, a slide rail 5, a slider 6, and a battery cell Positioning block 7, support push rod 8, support push rod fixing block 9, magnet cylinder 10, magnet 11, magnet fixing plate 12, support push rod cylinder 13, reclaiming cylinder 14, servo motor 15, flip plate 16, connecting shaft Device 17, connecting shaft 18, sliding sleeve 19, baffle plate 20, turning motor 21, pen-shaped cylinder 22, bracket cylinder 23, bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com