Power conversion device

A technology of a power conversion device and a judging device, which is applied in the direction of controlling electromechanical transmission devices, measuring devices, and measuring electrical variables, etc., can solve the problems of inability to disconnect the state and inability to detect bad connections, and achieve the effect of increasing the cost of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

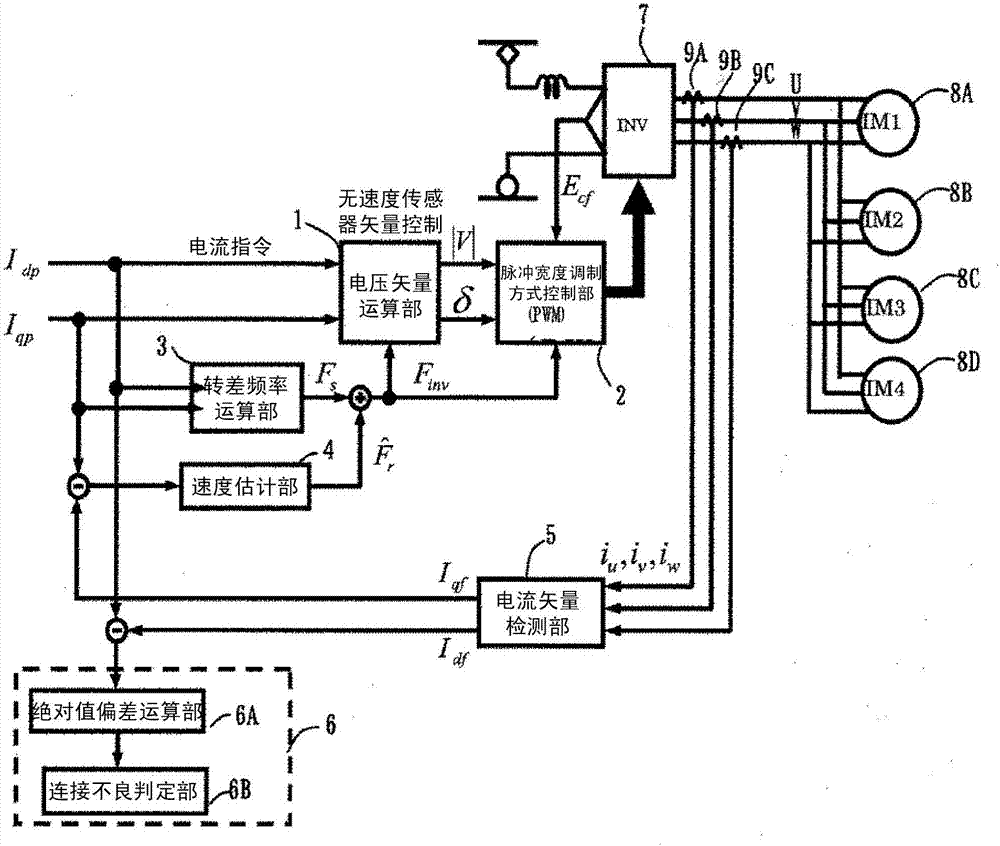

[0041] figure 1 A control block diagram of the drive control device for a railway vehicle in the first embodiment of the present invention is shown. Such as figure 1 As shown, DC power obtained from overhead lines via a pantograph is supplied to the inverter device 7 , and four induction motors 8A, 8B, 8C, and 8D are connected to the AC side of the inverter device 7 . These four induction motors 8A, 8B, 8C, and 8D are connected in parallel with each other, and vector control is performed by one inverter device 7 . The switching elements provided inside the inverter device 7 are switched based on the gate signal output from the pulse width modulation system control unit (PWM control unit) 2, thereby switching the four induction motors connected in parallel to the inverter device 7 8A, 8B, 8C, 8D provide the desired AC power.

[0042] The drive control device in this embodiment includes: a voltage vector calculation unit 1 that outputs a voltage command value and phase comman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com