Abrasive composition

A composition and abrasive technology, applied in the direction of polishing compositions containing abrasives, other chemical processes, chemical instruments and methods, etc., to achieve the effect of high surface finish and high cutting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

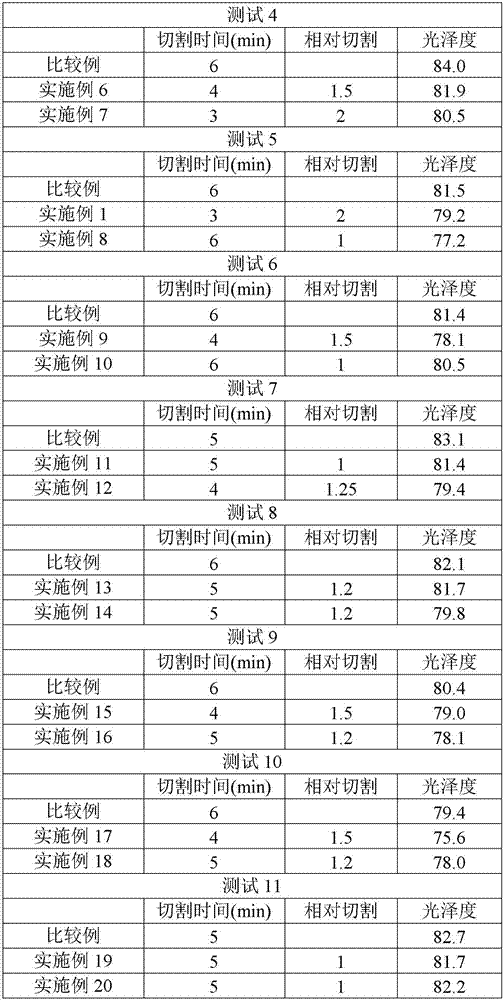

Examples

Embodiment approach

[0053] 1. An abrasive composition comprising: an organic solvent; a nonionic surfactant comprising a block copolymer of polypropylene oxide and polyethylene oxide; particulate abrasives; water; and a cosurfactant which, in combination with the remaining components of the abrasive composition, causes the abrasive composition to form a stable oil-in-water emulsion.

[0054] 2. The composition according to embodiment 1, wherein the nonionic surfactant has a hydrophilic-lipophilic balance in the range of 1 to 12.

[0055] 3. The composition according to embodiment 2, wherein the nonionic surfactant has a hydrophilic-lipophilic balance in the range of 1 to 7.

[0056] 4. The composition according to any one of embodiments 1 to 3, wherein the cosurfactant is nonionic and has a hydrophilic-lipophilic balance in the range of 10 to 20.

[0057] 5. The composition according to any one of embodiments 1 to 4, wherein the organic solvent is an aliphatic hydrocarbon present in an amount ra...

Embodiment 1

[0123] A 400 gram batch of polishing compound was prepared as follows. 64 grams of Exxsol D80, 20 grams of Tween 80 and 12 grams of Parol 70 were added to a mixer (Dispermat CV2-FHV, obtained from VMA-Getzmann, Reichshof, Germany) and mixed for 15 minutes at approximately 23°C. Then, 2 grams of triethanolamine, 222.6 grams of water, and 8 grams of glycerin were added to the mixer and mixed under low shear for 10-15 minutes. Then 60 grams of Grind-1, 4 grams of NIS1 and 0.4 grams of Kathon CG were added and mixing continued until a uniform dispersion was formed (approximately 15 minutes). 7 grams of Acusol 820 were slowly added to the dispersion while increasing the shear rate. Mixing was continued for an additional 30 minutes under high shear.

Embodiment 2

[0125] The procedure generally described in Example 1 was repeated, replacing 60 grams of Abrasive-1 with 60 grams of Abrasive-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com