Oil-in-water emulsion gel composition, external preparation for skin and producing method of oil-in-water emulsion composition

An emulsified composition, an oil-in-water technology, which is applied in the directions of skin care preparations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of difficulty in combining a large amount of oily ingredients, unacceptable, and low moisturizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

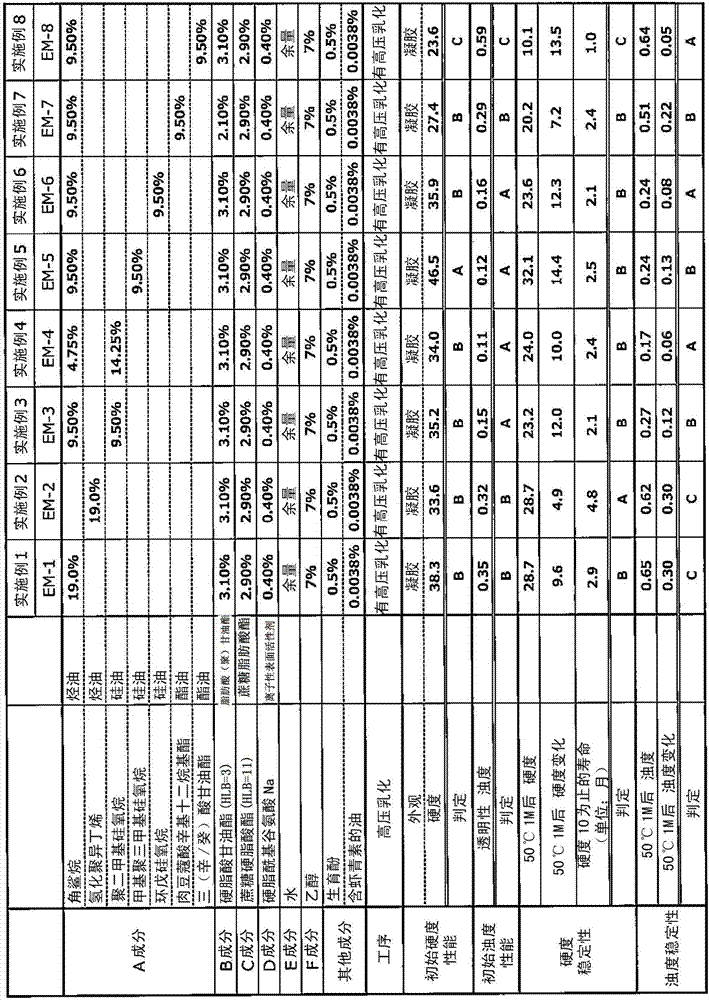

Embodiment 1~ Embodiment 8

[0202] Among the components described in Table 1 below, component C, component D, component E, and ethanol as component F were heated and dissolved at 70° C. for 45 minutes to obtain an aqueous phase composition A.

[0203] Component A, component B, other components of tocopherol and astaxanthin-containing oil (Haematococcus extract, ASTOTS-S, Fujifilm Co., Ltd., containing 20% astaxanthin) listed in the following Table 1 ) was heated at 70° C. for 30 minutes to dissolve, thereby obtaining an oil phase composition A.

[0204] While stirring the obtained water phase composition A, add the obtained oil phase composition A to the water phase composition A, using an ultrasonic homogenizer (model: US-600, Nippon Seiki Seisakusho Co., Ltd.), every 100g. Sonicate for 1 minute to obtain a pre-emulsion.

[0205] Next, the obtained pre-emulsion was subjected to high-pressure emulsification at a pressure of 245 MPa using an ultra-high-pressure emulsification device (model name: Ultima...

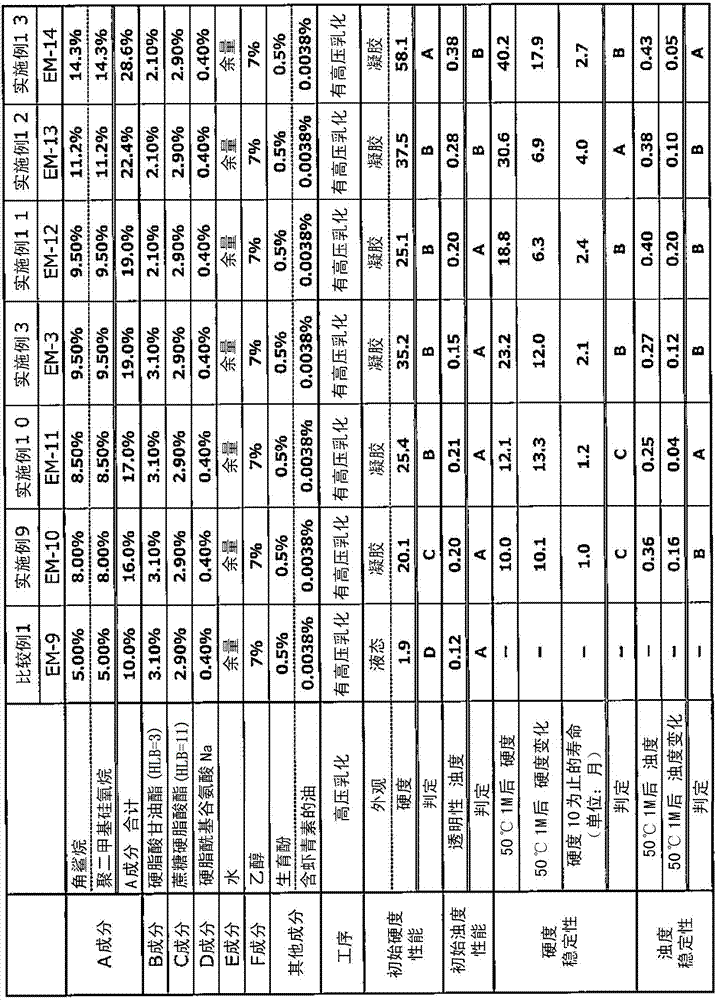

Embodiment 9~ Embodiment 13

[0281] [Example 9 to Example 13, Comparative Example 1]

[0282] An emulsified composition was prepared in the same manner as in Example 1 according to the recipe in Table 2 below, and the obtained emulsified composition was evaluated in the same manner as in Example 1. The results are collectively described in Table 2 below. As a comparative example, the formulation and evaluation results of Example 3 are listed in Table 2.

[0283] 【Table 2】

[0284]

[0285] As can be seen from the results in Table 2, the emulsified compositions of Examples 9 to 13, like the emulsified composition of Example 3, have good transparency and are emulsified compositions having practically sufficient gel hardness. From the evaluation results of Example 3 and Examples 9 to 13, it can be seen that when the content of component A is increased, the gel hardness tends to increase.

[0286] On the other hand, in Comparative Example 1 in which the content of component A was 15% or less, the hardne...

Embodiment 14~ Embodiment 17、 comparative example 2~ comparative example 6

[0288] An emulsified composition was prepared in the same manner as in Example 1 according to the recipe in Table 3 below, and the obtained emulsified composition was evaluated in the same manner as in Example 1. The results are collectively described in Table 3 below. As a comparative example, the formula and evaluation results of Example 3 are described in Table 3.

[0289] 【table 3】

[0290]

[0291] As can be seen from the results in Table 3, the emulsified compositions of Examples 14 to 17, like the emulsified composition of Example 3, have good transparency and are emulsified compositions having practically sufficient gel hardness. From the evaluation results of Example 3 and Examples 14 to 17, it was found that by using fatty acid (poly)glycerides as the B component, both transparency and gel hardness were further improved.

[0292] On the other hand, when a fatty acid (poly)glyceride (comparative component) with an HLB exceeding 7 was used or a surfactant (compara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com