Electric automobile air conditioner refrigeration system

A technology for air-conditioning and refrigeration and electric vehicles, which is applied to vehicle components, air handling equipment, heating/cooling equipment, etc. It can solve the problems of reduced precision, high cost, and inability to effectively maintain a constant temperature in the car, achieving controllable output, The effect of shrinking space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

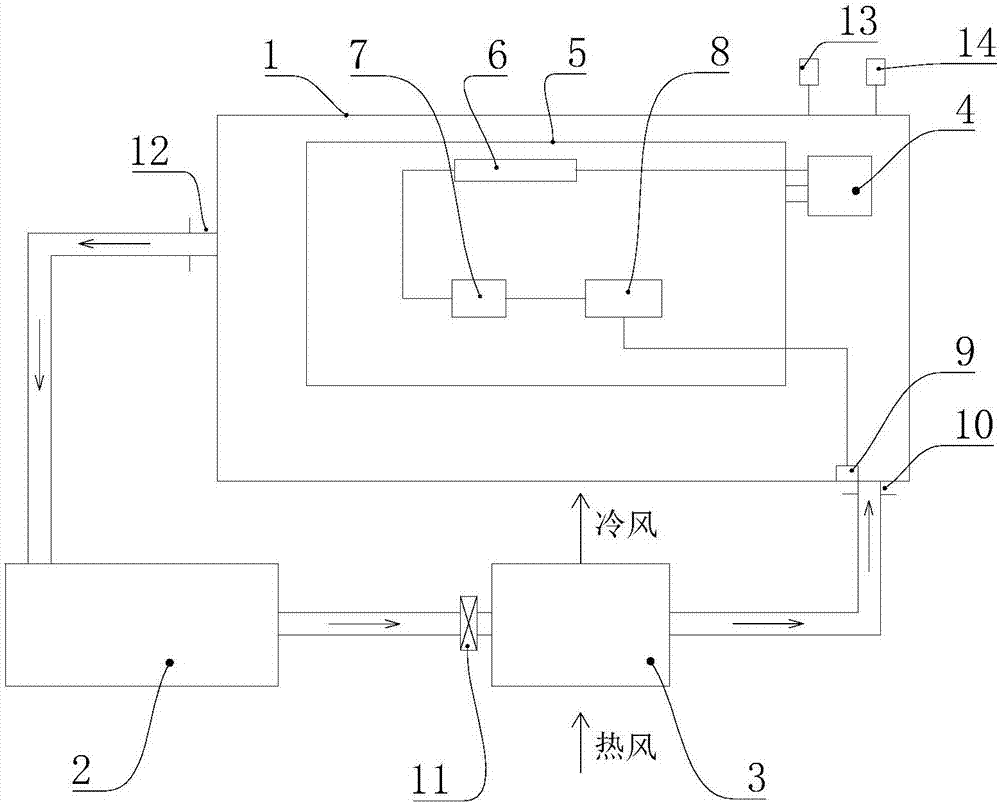

[0016] see figure 1 As shown, an electric vehicle air-conditioning and refrigeration system includes an electric compressor assembly 1, a condenser 2 and an evaporator 3 connected in series in sequence. The electric compressor assembly 1 includes a motor 4, and the compressor connected to the motor 4 is controlled 5 and the control module for controlling the rotating speed of the motor 4; the control module includes a main control single-chip microcomputer 6 connected in series, a temperature control single-chip microcomputer 7, an analog-to-digital converter 8 and a thermistor 9, and the main control single-chip microcomputer 6 is connected with the motor 4; The above-mentioned thermistor 9 is arranged at the suction port 10 of the evaporator 3, and the rotation speed of the motor 4 is adjusted through the thermistor 9 sensing the stability of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com