Mems gyroscope chip wafer level testing system and testing and screening method

A test system, wafer-level technology, applied in microstructure devices, sorting, microstructure technology, etc., can solve the problems of low measurement accuracy, long test time, unsuitable for batch testing of production lines, etc., to save packaging costs, accurate The effect of effective testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific drawings and embodiments.

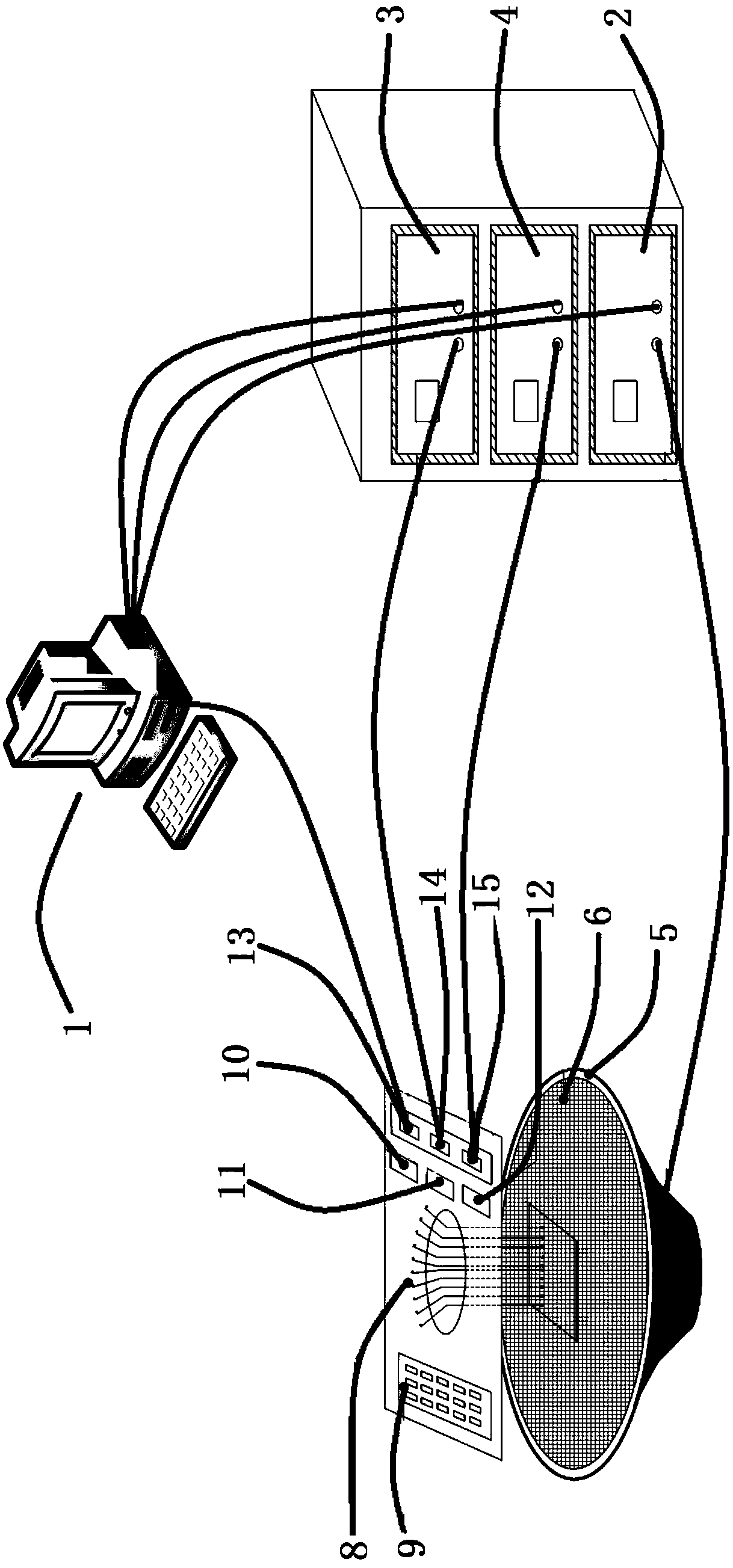

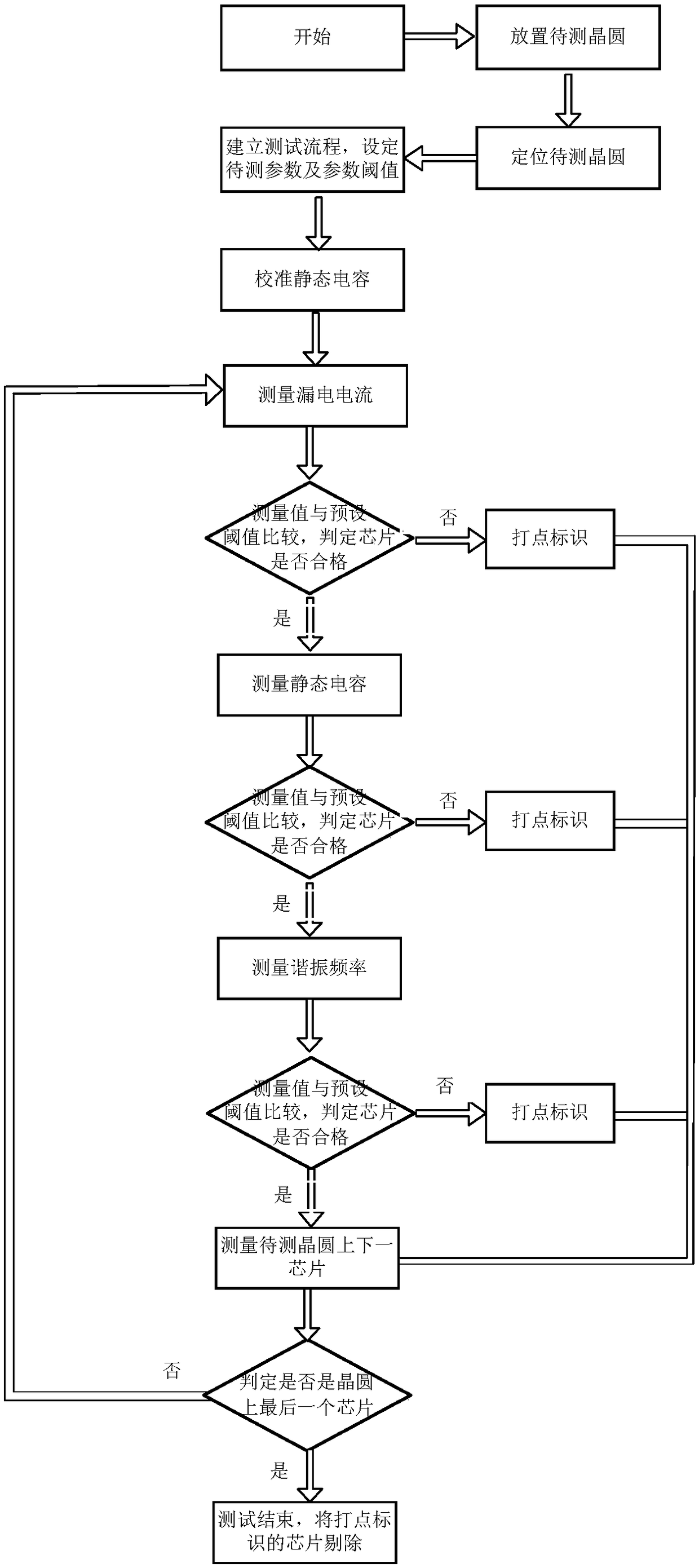

[0034] According to attached figure 1 Said, in order to be able to realize the fast and effective test of MEMS gyroscope wafer-level chip, the present invention has designed MEMS gyroscope chip wafer-level test system, it is characterized in that: comprise control host computer 1 and be used to place the carrier sheet of wafer 6 to be tested Platform 5, a program-controlled motor 16 is provided below the slide table 5, and the program-controlled motor 16 is connected to the control host 1 through the probe station controller 2; a probe card is fixed directly above the slide table 5 with a clamp 7. The probe card 7 is connected to the electrode of the wafer 6 to be tested on the slide table 5 through the probe 8; the probe card 7 is provided with an RS485 interface 13, a BNC triaxial interface 14 and a BNC coaxial interface 15. The probe card 7 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com