High-efficiency aerobic granular sludge continuous flow reactor and running method

An aerobic granular sludge and reactor technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problem of large water head loss, low equipment utilization rate, and low volume utilization rate and other problems, to achieve the effect of saving floor space, saving operation and management costs, and improving separation effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

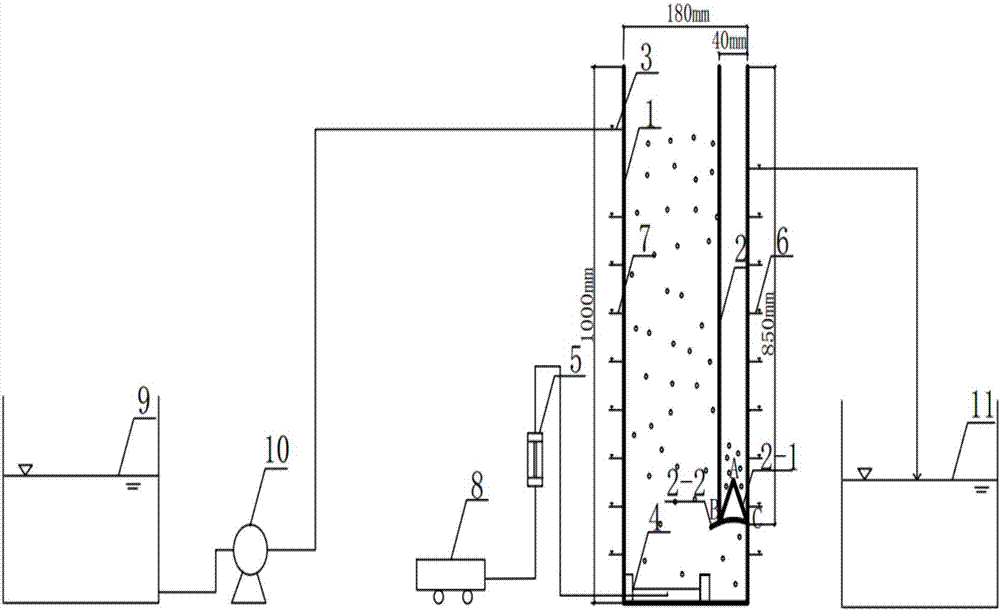

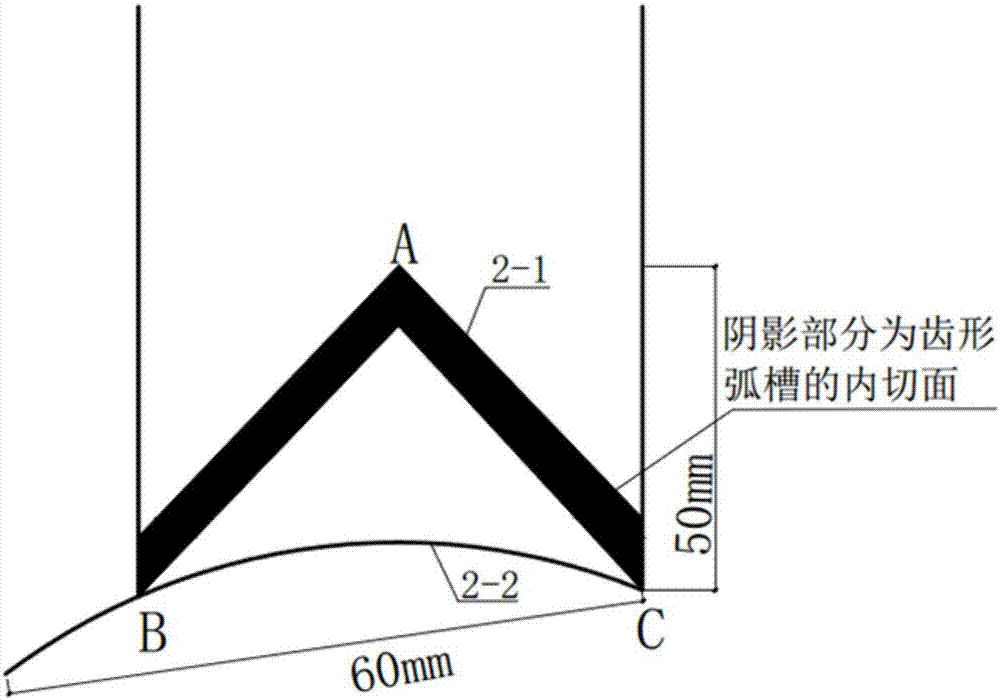

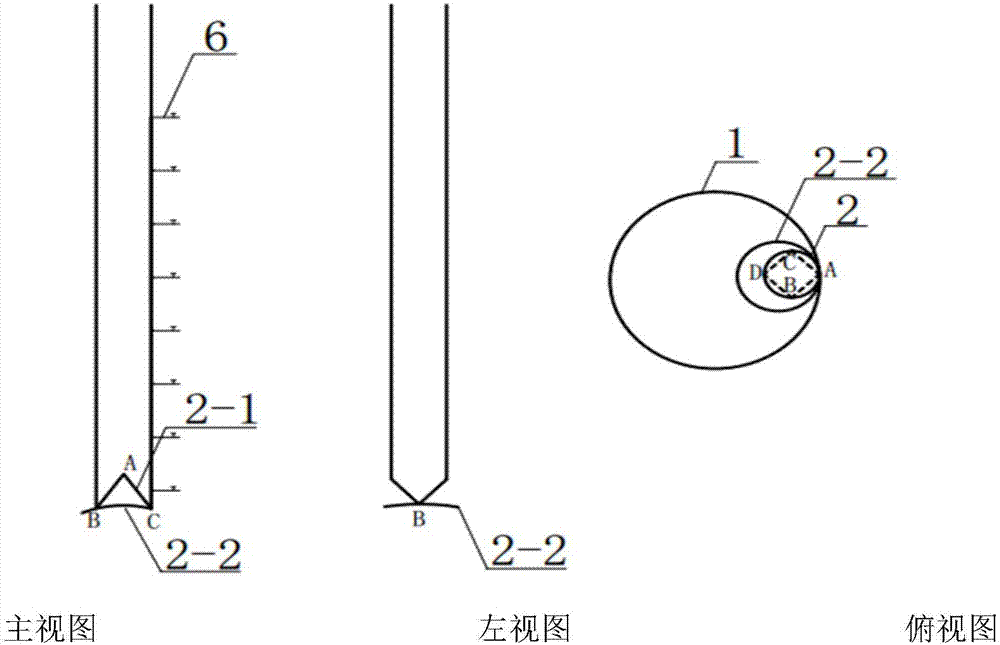

[0028] Such as figure 1 As shown, the present invention is a high-efficiency aerobic granular sludge continuous flow reactor, including a reactor main body 1, a water inlet system, an aeration system, and a drainage system. The outer diameter of the reactor main body 1 is 180 mm. When the diameter of the pipe is 40mm, the sedimentation performance of granular sludge is the best, and it is easier to separate mud and water. One side of the wall of the built-in high-efficiency sedimentation tube is glued to the wall of the main body of the reactor. The bottom is an upwardly convex spherical surface, which can effectively prevent the gas from entering the sedimentation tube, and can realize the sewage treatment of the reactor under the operating condition of continuous flow. At the same time, the upward convex spherical design can make the granular sludge flow out of the sedimentation pipe better, and at the same time, the mud-water mixture flow outside the sedimentation pipe can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com