Method of separating and purifying polymethoxyflavone compounds from tangerine fruits

A technology for separating and purifying polymethoxyflavonoids is applied in the field of separating and purifying polymethoxyflavonoids from citrus fruits, and can solve the problems of high cost, low monomer purity, low preparation amount, complicated process, etc. Low, safe and easy to operate production process, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

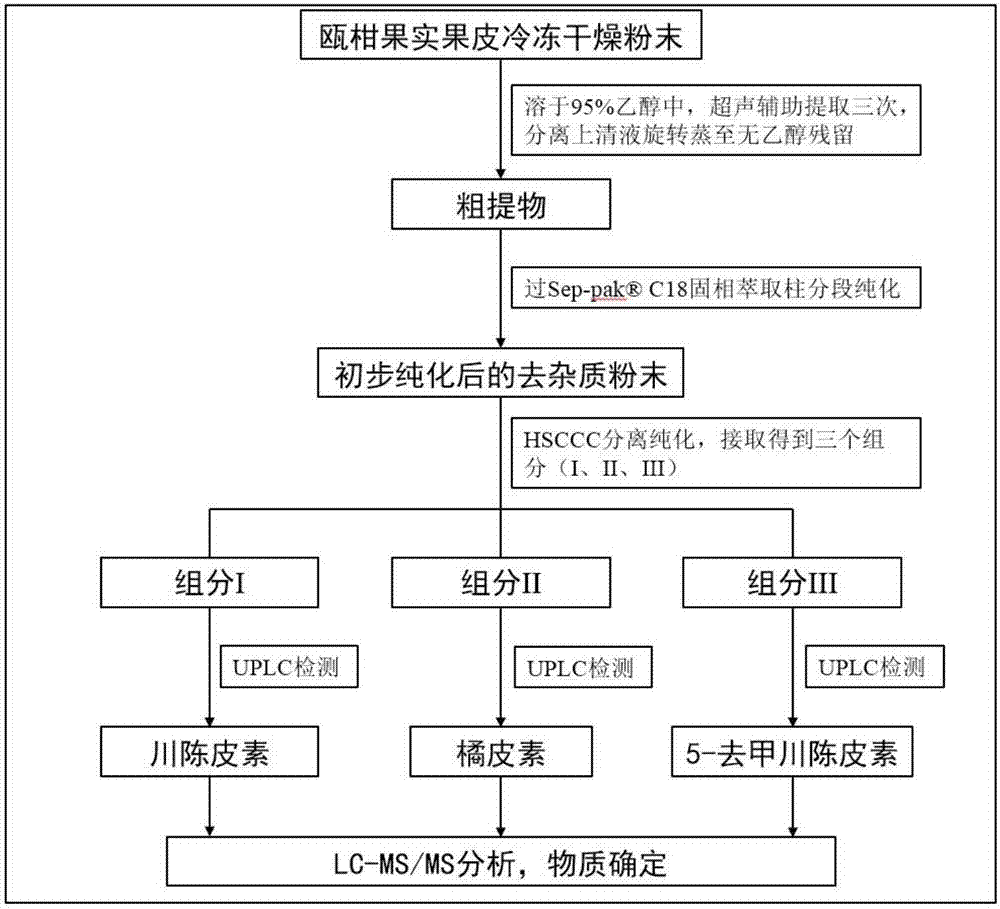

[0022] The operating method of the present invention for separating and purifying nobiletin, tangeretin and 5-nornobiletin is carried out according to the following steps, see figure 1 :

[0023] (1) Ultrasonic-assisted extraction: 10.3 g of freeze-dried Ou mandarin fruit peel powder was ultrasonically extracted three times (25°C) with 95% ethanol (solid-to-liquid ratio 1:20), each time for 45 minutes, after vacuum filtration, the supernatant was combined , evaporated to dryness on a rotary evaporator to an ethanol-free phase, and dissolved in deionized water to obtain an aqueous solution of the crude extract.

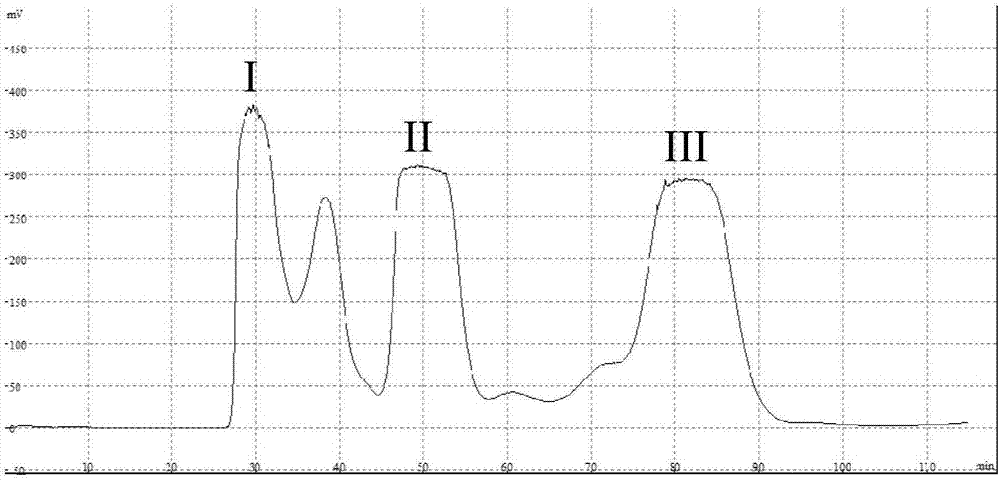

[0024] (2) C18 solid-phase extraction column for sugar removal and segmentation: take about 5 mL of the crude extract aqueous solution obtained in step (1) and load it C18 solid-phase extraction column, after loading, the solid-phase extraction column is first eluted with deionized water for 25 times of column bed volume (BV) to remove impurities with higher polar...

Embodiment 2

[0027] The operating method of the present invention for separating and purifying nobiletin, tangeretin and 5-nornobiletin is carried out according to the following steps, see figure 1 :

[0028] (1) Ultrasonic-assisted extraction: 11.2 g of freeze-dried Ou mandarin fruit peel powder was ultrasonically extracted three times with 95% ethanol (solid-to-liquid ratio 1:20) (25°C), each time for 45 minutes, vacuum filtered, and the supernatant was combined , evaporated to dryness on a rotary evaporator to an ethanol-free phase, and dissolved in deionized water to obtain an aqueous solution of the crude extract.

[0029] (2) C18 solid-phase extraction column for sugar removal and segmentation: take about 5 mL of the crude extract aqueous solution obtained in step (1) and load it C18 solid-phase extraction column, after loading, the solid-phase extraction column is first eluted with deionized water for 25 times of column bed volume (BV) to remove impurities with higher polarity, a...

Embodiment 3

[0031] Embodiment 3 The present invention carries out the screening determination of influence factor by following test

[0032] 1. Selection of purification materials

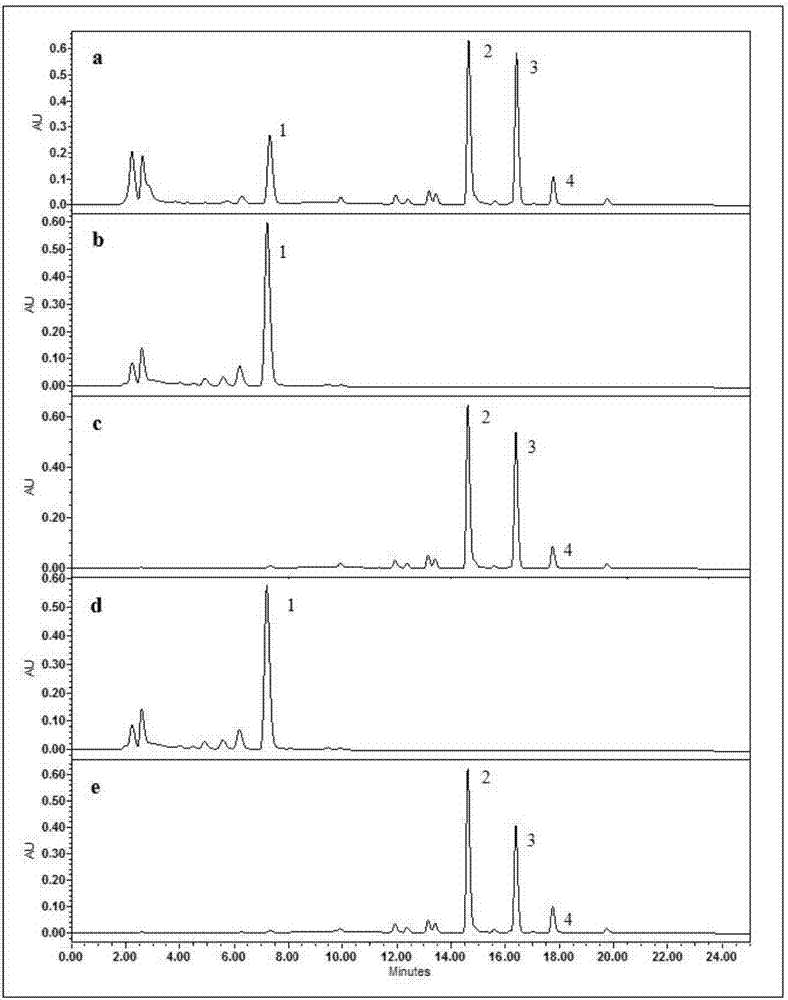

[0033] The peel of fresh Ou mandarin fruit is freeze-dried to constant weight and ground into powder with a mill. Take a certain quality of freeze-dried Ou mandarin peel powder and use 95% ethanol (solid-to-liquid ratio: 1:20) to ultrasonically extract for 45 minutes (25°C), repeat twice, and after vacuum filtration, combine the supernatant for multiple use. UPLC analysis of methoxylated flavonoids. The UPLC mobile phase includes deionized water (solution A) and chromatographic acetonitrile (solution B), using gradient elution, the detection wavelength is 330nm, the temperature is room temperature (25 ° C), the injection volume is 2 μl, and the flow rate is 0.3ml / min. The conditions are: solvent B: 0-5min, 20%, 5-8min: 20%-34%; 8-20min: 34%-60%, 20-22min: 60%-100%, 22~23min: 100% Change, 23-24min: 100%-20%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com