Device and method for producing ultra-low sulphur gasoline by inferior catalytic gasoline hydrogenation upgrading

A catalytic gasoline and hydrogenation upgrading technology, which is applied in the fields of hydrotreating process, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of waste of resources and large loss of octane number, and achieve energy saving and small loss of octane number , the effect of good combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

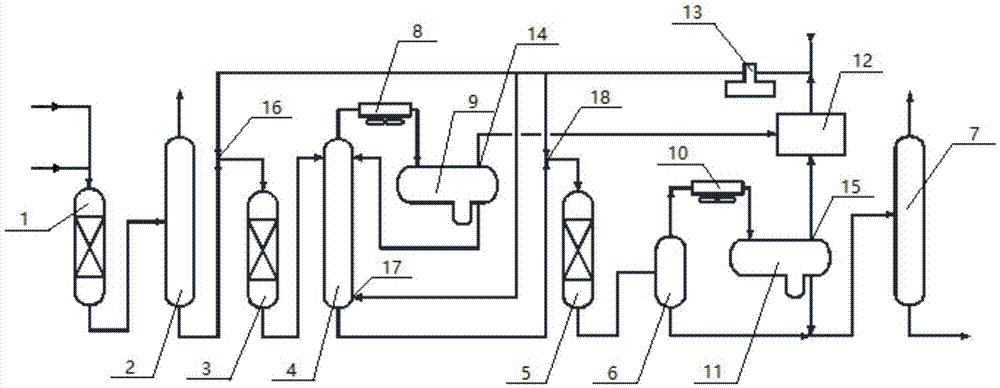

[0069] This embodiment provides a device for producing ultra-low-sulfur gasoline by hydrogenation and upgrading of inferior catalytic gasoline. Stripping tower 4, octane recovery reactor 5, heat separation tank 6, stabilizing tower 7, and stripping tower overhead air cooler 8, reflux tank 9, reaction product air cooler 10, cold separation tank 11 and the circulation connected in sequence Hydrogen desulfurizer 12 and circulating hydrogen compressor 13.

[0070] Hydrogen sulfide stripper 4 top outlets, stripper top air cooler 8, the inlet of reflux tank 9 are connected in sequence, and the outlet of reflux tank 9 is connected with hydrogen sulfide stripper 4 top inlets; The top outlet of heat separation tank 6, The inlets of the reaction product air cooler 10 and the cold separation tank 11 are connected in sequence, and the outlet of the cold separation tank 11 is connected with the connecting pipeline between the hot separation tank 6 and the stabilizing tower 7 .

[0071] Th...

Embodiment 2

[0073] In this example, the device for producing ultra-low-sulfur gasoline by hydro-upgrading of inferior catalytic gasoline provided in Example 1 is used, and the inferior-quality catalytic gasoline is subjected to hydro-upgrading treatment to produce ultra-low-sulfur gasoline.

[0074] Introduce inferior catalytic gasoline and fresh hydrogen into the pre-hydrogenation reactor 1, under hydrogen partial pressure 2.5Mpa, temperature 150°C, volume space velocity 4.0h -1 The hydrogenation reaction is carried out under certain conditions, wherein the volume ratio of fresh hydrogen to inferior catalytic gasoline is 5:1, and the pre-hydrogenation catalyst includes the following components in mass percentage: Ni and Cu oxides 20%, and the balance is alumina carrier. The specific surface area of the prehydrogenation catalyst is 260m 2 / g, the pore volume is 0.45ml / g. The product obtained by the above hydrogenation reaction enters the fractionation tower 2 for fractionation to obta...

Embodiment 3

[0078] In this example, the device for producing ultra-low-sulfur gasoline by hydro-upgrading of inferior catalytic gasoline provided in Example 1 is used, and the inferior-quality catalytic gasoline is subjected to hydro-upgrading treatment to produce ultra-low-sulfur gasoline.

[0079] Introduce inferior catalytic gasoline and fresh hydrogen into the pre-hydrogenation reactor 1, under hydrogen partial pressure 2.0Mpa, temperature 100°C, volume space velocity 2.5h -1 The hydrogenation reaction is carried out under certain conditions, wherein the volume ratio of fresh hydrogen to inferior catalytic gasoline is 4:1, and the pre-hydrogenation catalyst includes the following components in mass percentage: 12% oxides of Zn and Ge, and the balance is alumina carrier. The specific surface area of the prehydrogenation catalyst is 220m 2 / g, the pore volume is 0.25ml / g. The product obtained by the above hydrogenation reaction enters the fractionation tower 2 for fractionation to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com