Process method for thioalkylation of thiophene

A process method and technology of thiophene sulphane, which are applied in the directions of hydrotreating process, petroleum industry, hydrocarbon oil treatment products, etc., can solve the problems of low removal rate of thiophene sulphur and large loss of octane number, etc., and achieve high product yield , the effect of improving the removal rate and improving the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

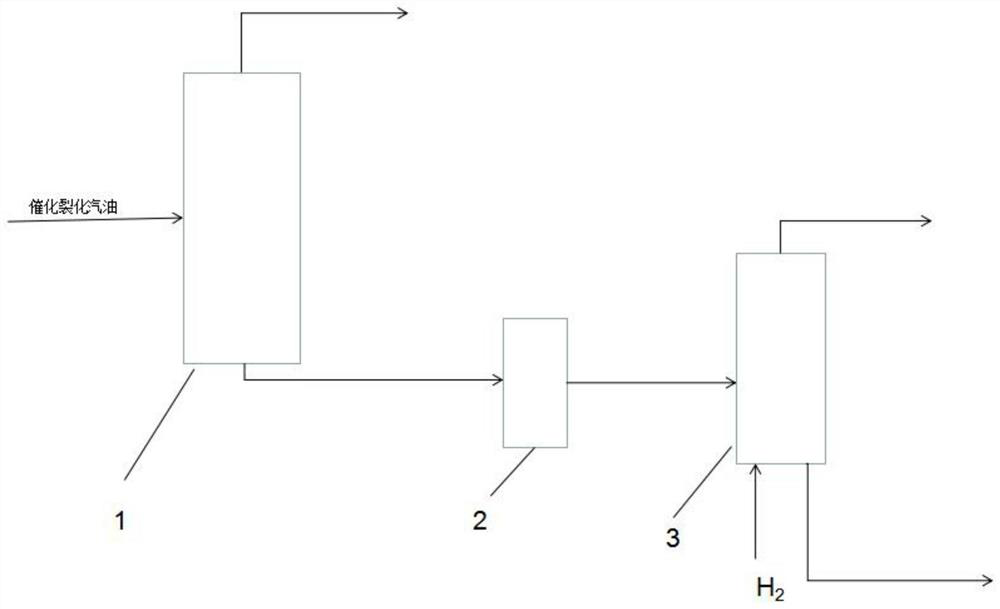

[0028] A kind of processing method of thiophene sulfur alkylation, comprises the following steps:

[0029] (1) Fractional distillation separation: FCC gasoline is used as the reaction raw material, and the FCC gasoline enters the fractionation tower 1 for fractionation to obtain light components and heavy components; the light components are discharged from the top of the tower, and the heavy components are discharged from the bottom of the tower and then enter the in the reactor;

[0030] The operating conditions of the fractionation tower are: tower top temperature 50°C, pressure 0.1MPa; tower bottom temperature 70°C, pressure 0.5MPa.

[0031] (2) Alkylation reaction: the heavy component in the step (1) is treated with 0.1h -1 After the space velocity enters the prereactor 2 (fixed bed reactor), the thiophene sulfur and olefins in the heavy component undergo alkylation under the catalysis of the resin catalyst KC115-2 produced by Kairui Environmental Protection Technology C...

Embodiment 2

[0037] A kind of processing method of thiophene sulfur alkylation, comprises the following steps:

[0038] (1) Fractional distillation separation: FCC gasoline is used as the reaction raw material, and the FCC gasoline enters the fractionation tower 1 for fractionation to obtain light components and heavy components; the light components are discharged from the top of the tower, and the heavy components are discharged from the bottom of the tower and then enter the in the reactor;

[0039] The operating conditions of the fractionation tower are: tower top temperature 60°C, pressure 5MPa; tower bottom temperature 78°C, pressure 6MPa.

[0040] (2) Alkylation reaction: the heavy component in step (1) with 5h -1 After the space velocity enters the prereactor 2 (fixed bed reactor), the thiophene sulfur and olefins in the heavy component undergo alkylation under the catalysis of the resin catalyst KC115-2 produced by Kairui Environmental Protection Technology Co., Ltd. in the prere...

Embodiment 3

[0046] A kind of processing method of thiophene sulfur alkylation, comprises the following steps:

[0047] (1) Fractional distillation separation: FCC gasoline is used as the reaction raw material, and the FCC gasoline enters the fractionation tower 1 for fractionation to obtain light components and heavy components; the light components are discharged from the top of the tower, and the heavy components are discharged from the bottom of the tower and then enter the in the reactor;

[0048]The operating conditions of the fractionation tower are: tower top temperature 70°C, pressure 10MPa; tower bottom temperature 80°C, pressure 12MPa.

[0049] (2) Alkylation reaction: the heavy component in the step (1) with 10h -1 After the space velocity enters the prereactor 2 (fixed bed reactor), the thiophene sulfur and olefins in the heavy component undergo alkylation under the catalysis of the resin catalyst KC115-2 produced by Kairui Environmental Protection Technology Co., Ltd. in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com