Environment-friendly biomass fuel and production process thereof

A biomass fuel and biomass technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of large smoke and dust, difficulty in biomass utilization, environmental pollution, etc., and achieve high calorific value, excellent combustion performance, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

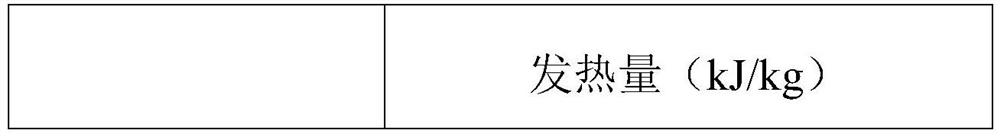

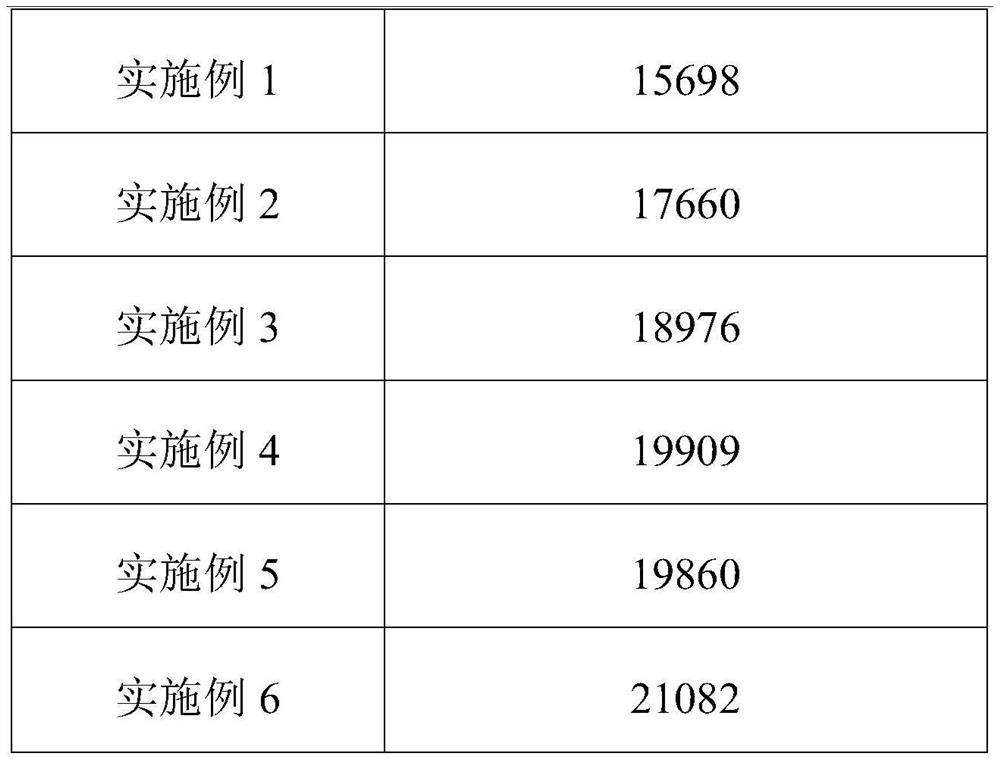

Embodiment 1

[0064] The production process of environmentally friendly biomass fuel comprises the following steps:

[0065] (1) In parts by weight, 85 parts of biomass substrates and 7 parts of fillers are put into a mixer, and stirred at 400 rpm for 50 minutes to obtain a uniformly mixed premix;

[0066] (2) Extrude the premix with a molding granulator to obtain a density of 1.0g / cm 3 , a biomass fuel with a diameter of 8mm and a moisture content of 4wt%.

[0067] The filler is composed of chlorite and tourmaline in a mass ratio of 3:4.

[0068] The preparation method of described biomass matrix is:

[0069] Litchi shells, litchi cores, durian shells, durian cores, longan shells, longan cores, pomegranate skins, and pomegranate seeds are cleaned and dried, respectively crushed and passed through a 30-mesh sieve to obtain litchi shell powder, litchi core powder, and durian shell powder , durian core powder, longan shell powder, longan core powder, pomegranate peel powder, pomegranate se...

Embodiment 2

[0071] The production process of environmentally friendly biomass fuel comprises the following steps:

[0072] (1) In parts by weight, 85 parts of biomass substrates and 7 parts of fillers are put into a mixer, and stirred at 400 rpm for 50 minutes to obtain a uniformly mixed premix;

[0073] (2) Extrude the premix with a molding granulator to obtain a density of 1.0g / cm 3 , a biomass fuel with a diameter of 8mm and a moisture content of 4wt%.

[0074] The filler is composed of chlorite and tourmaline in a mass ratio of 3:4.

[0075] The preparation method of described biomass matrix is:

[0076] S1: Clean litchi shells, litchi cores, durian shells, durian cores, longan shells, longan cores, pomegranate peels, and pomegranate seeds, dry them, crush them and pass through a 30-mesh sieve to obtain litchi shell powder, litchi core powder, and durian Shell powder, durian core powder, longan shell powder, longan core powder, pomegranate peel powder, pomegranate seed powder, desc...

Embodiment 3

[0081] The production process of environmentally friendly biomass fuel comprises the following steps:

[0082] (1) In parts by weight, 85 parts of biomass substrates and 7 parts of fillers are put into a mixer, and stirred at 400 rpm for 50 minutes to obtain a uniformly mixed premix;

[0083] (2) Extrude the premix with a molding granulator to obtain a density of 1.0g / cm 3 , a biomass fuel with a diameter of 8mm and a moisture content of 4wt%.

[0084] The filler is composed of chlorite and tourmaline in a mass ratio of 3:4.

[0085] The preparation method of described biomass matrix is:

[0086] S1: Clean litchi shells, litchi cores, durian shells, durian cores, longan shells, longan cores, pomegranate peels, and pomegranate seeds, dry them, crush them and pass through a 30-mesh sieve to obtain litchi shell powder, litchi core powder, and durian Shell powder, durian core powder, longan shell powder, longan core powder, pomegranate peel powder, pomegranate seed powder, desc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com