Solid glass cleaner and preparation method thereof

A cleaning agent and glass technology, applied in the field of cleaning agents, can solve the problems of inconvenient product transportation and sales, and achieve the effects of light weight, scientific compatibility, and low transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

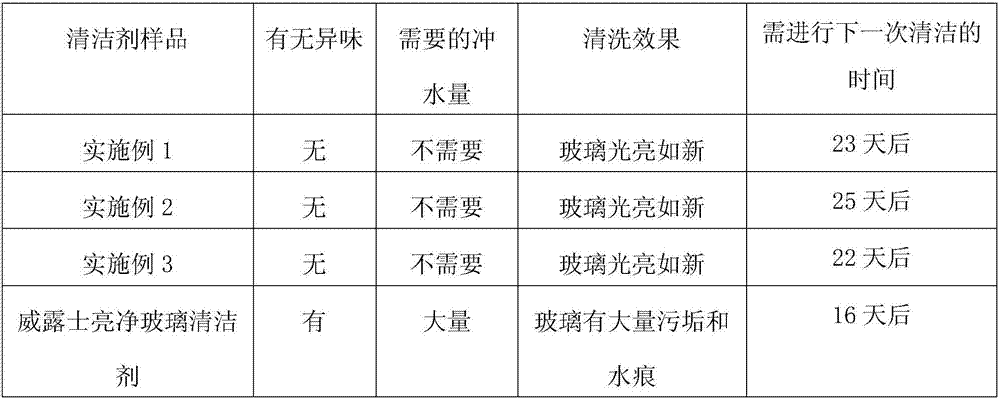

Examples

Embodiment 1

[0034] A kind of solid glass cleaner provided by the present embodiment is made up of the raw material of following weight part: Cocamidopropyl betaine 12 parts, sorbitol 6 parts, sodium benzoate 4 parts, coconut oil fatty acid diethanolamide 4 parts, 5 parts of sodium sulfate, 4 parts of myristyl alcohol, 5 parts of calcium silicate, 1 part of table salt, 3 parts of sodium tripolyphosphate, 5 parts of ethanol, 6 parts of zeolite powder, 3 parts of mica powder, 10 parts of cleaning solution and 15 parts of water Wherein, the cleaning solution is composed of the following raw materials in parts by weight: 12 parts of avocado, 10 parts of glycerin, 15 parts of acacia oil, 5 parts of sodium hydroxide and 20 parts of water.

[0035] The preparation technology of above-mentioned solid glass cleaner comprises the steps:

[0036] (1) Preparation of cleaning solution

[0037] a. Weigh 12 parts by weight of avocado, 10 parts by weight of glycerin and 15 parts by weight of acacia oil, ...

Embodiment 2

[0050] A kind of solid glass cleaner provided by the present embodiment is made up of the raw material of following weight part: Cocamidopropyl betaine 15 parts, sorbitol 9 parts, sodium benzoate 6 parts, coconut oil fatty acid diethanolamide 6 parts, 7 parts of sodium sulfate, 6 parts of myristyl alcohol, 7 parts of calcium silicate, 3 parts of table salt, 4 parts of sodium tripolyphosphate, 7 parts of ethanol, 9 parts of zeolite powder, 6 parts of mica powder, 15 parts of cleaning solution and 17 parts of water Wherein, the cleaning solution is composed of the following raw materials in parts by weight: 15 parts of avocado, 12 parts of glycerin, 18 parts of acacia oil, 7 parts of sodium hydroxide and 24 parts of water.

[0051] The preparation technology of above-mentioned solid glass cleaner comprises the steps:

[0052] (1) Preparation of cleaning solution

[0053] a. Weigh 15 parts by weight of avocado, 12 parts by weight of glycerin and 18 parts by weight of acacia oil,...

Embodiment 3

[0066] A kind of solid glass cleaner provided by the present embodiment is made up of the raw material of following weight part: Cocamidopropyl betaine 18 parts, sorbitol 12 parts, sodium benzoate 8 parts, coconut oil fatty acid diethanolamide 8 parts, 10 parts of sodium sulfate, 8 parts of myristyl alcohol, 9 parts of calcium silicate, 5 parts of table salt, 5 parts of sodium tripolyphosphate, 10 parts of ethanol, 12 parts of zeolite powder, 8 parts of mica powder, 20 parts of cleaning solution and 20 parts of water Wherein, the cleaning solution is made up of the following raw materials in parts by weight: 18 parts of avocado, 15 parts of glycerin, 22 parts of acacia oil, 10 parts of sodium hydroxide and 28 parts of water.

[0067] The preparation technology of above-mentioned solid glass cleaner comprises the steps:

[0068] (1) Preparation of cleaning solution

[0069] a. Weigh 18 parts by weight of avocado, 15 parts by weight of glycerin and 22 parts by weight of acacia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com