Photobioreactor for microalgae culture

A technology of photobioreactor and photoreaction, applied in photobioreactor, specific-purpose bioreactor/fermenter, combination of bioreactor/fermenter, etc., can solve the difficulty of cleaning the inner wall of photobioreactor, Low light energy utilization efficiency of microalgae, increased cost of microalgae cultivation, etc., to avoid sticky wall growth, improve photosynthetic efficiency, and prolong suspension time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Other advantages, objectives and features of the present invention will be partially embodied by the following description, and partly will be understood by those skilled in the art through the research and practice of the present invention.

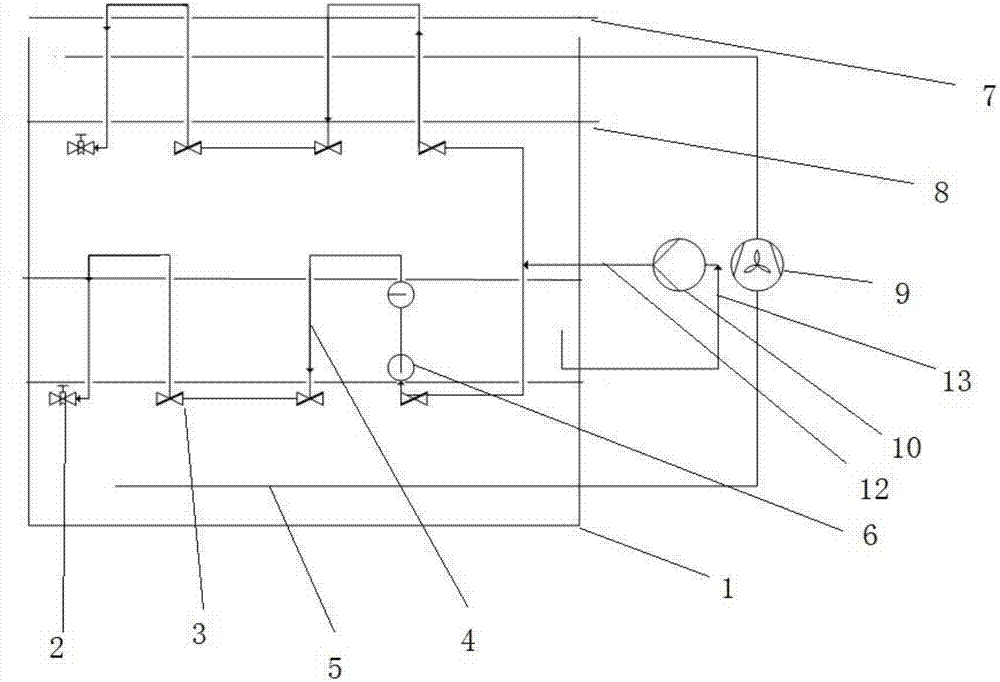

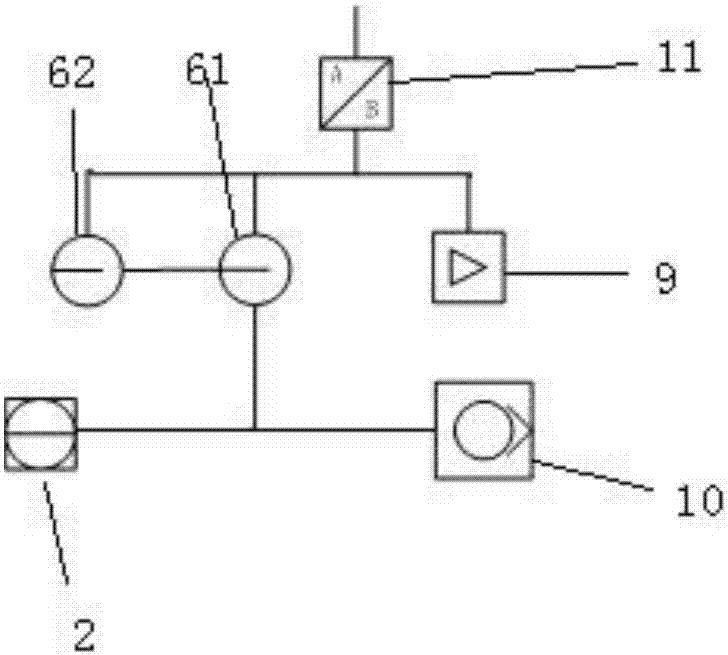

[0020] Such as figure 1 As shown, a photobioreactor for microalgae cultivation includes:

[0021] The culture pond 1 is rectangular in shape and 50cm in depth;

[0022] The aeration unit, which includes an aeration pump 9 and an aeration tube 5, is formed by the connection of the aeration tube 5 and the aeration pump 9. The aeration unit not only plays a role in regulating pH, but also suspends microalgae in the water , Improve the utilization rate of light energy;

[0023] The water circulation pump 10 has a water inlet connected to one end of a water inlet pipe 13, and the other end of the water inlet pipe 13 is placed at the bottom of the aquaculture pond 1;

[0024] The photoreaction unit includes a photoreaction tube 4, a lower positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com